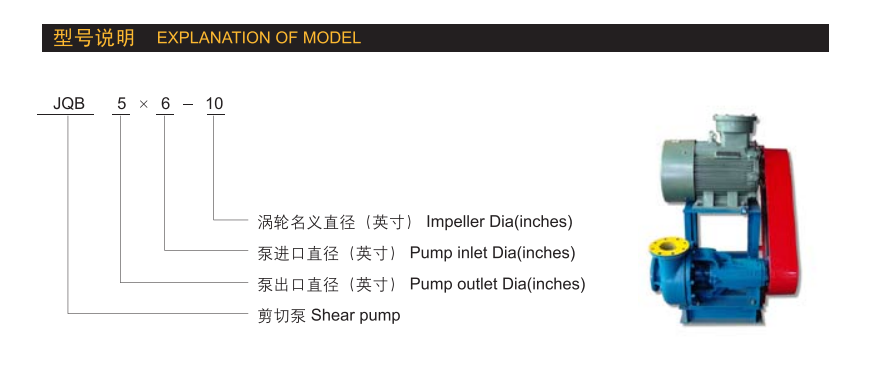

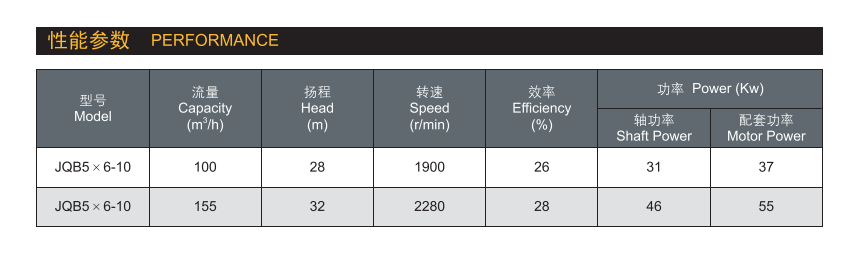

6x5x11/14 Drilling Fluid Shear Pump for Solid Control Equipment

-

Transport Package:

-

Wooden Pakage

-

Specification:

-

JQB5×6-10

-

Trademark:

-

JINGZHENG

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

Certification:

-

ISO 9001:2000 ISO 9001:2008 Other

-

Power Source:

-

Electric

-

Operation Pressure:

-

Atmospheric Pressure

-

Material:

-

Alloy

-

Type:

-

Sand Pump

-

Payment:

-

L/C T/T Other

-

Export Port:

-

Tianjin shanghai

-

Output:

-

50000 pics/year

-

Model NO:

-

JQB5×6-10

Quick Details

PRODUCT INTRODUCTION

Shear Pumps are an essential piece of equipment and part of the mud cleaning process. It is a mechanical device that is used for the purpose of pumping liquid and semi-solids. The principle used for the device to work is the high shear force that is produced in between the working head. A Shear Pump simply uses a high-speed rotor powered by an electric motor. They work on the fluid, creating a flow and shear.

The shear pumps have a hydration system attached, which quickly cuts and dilutes hydrated polymers. A unique mechanical composite steel technology is used in the shear pump to ensure that there is no leakage. The high wear-resistant metallic materials are used for the impellers and the casing, which prolongs their service life. The Impeller is structured in a way that is according to the principle of fluid mechanics and results in increased liquidity. The low shear force results in the efficient working of this Shear Pump.

Drilling shearing pump applies axial suction structure, consisting of a motor, pump seat, pump shell, impeller, shearing impeller, and other components. Vee belt and mechanical compound seal guarantee no leakage. There is a stainless turbine inside(which composes entrance bucket, main impeller, nozzle,catch compartment)and a shearing plate.

Shear Pump can mix effectively and hydrate completely the material added in the drilling fluid, save the mud material, reduce the time of configuration, and provide the performance mud for the shear drilling. Shear Pump is efficient equipment which provides the fast configuration and treatment mud for the user, the user satisfy with configuration high -performance mud.

Shearing pump can mix high property drilling mud very soon. Decrease the mixing time by much and enhance the drilling efficiency with structure cost control. guarantee pump can help much on eliminate “fish eye” phenomenon. It will help much on , drilling mud demand for whole a drilling.

MAIN FEATURES OF SHEAR PUMP

- Impeller

- Hydration system

- High-speed rotor

- Electric motor

- A power device

Benefits

- No modifications to existing piping required;

- FAG, SKF or other top brand bearing;

- Reduce drill cuttings by 50 microns;

- Economical and compact method of shearing polymers;

- Versatile stuffing box;

- Thick, strong concentric casing with replaceable casing wear pads;

- Casing gasket receded for protection;

- Replaceable stuffing box cover with dual stuff box bolts;

- Replaceable shaft sleeve prevents shaft wear;

- Machinery seals for maximum bearing protection come standard;

- Standard options : IECEX, ATEX, UL, DGMS, CE, Gost.

EXPLANATION OF SECTIONAL

The JQB5×6-10 shear pump adopts a set of compound seal for no leakage at stuffing box. Inside pump is a 300 series stainless steel turbine containing 44 nozzles, four scoops and shear plate. Fifty(50)% of the fluid is sheared twice each time thorugh the pump.This turbine shear pump is mounted on a special base with belts and sheaves to drive pump, OSHA type belt guard and a 75HP(55KW) explorsion U/L approved electric motor, 460 volt, 3 phase 60 cycle. Included is a special hopper(ZHP150) with nozzle sized for this application and one mud kit as a package in order to build a complete shear and hydration system. The pump is designed to give longer service life through the improved shaft seal.

WARNING

This pump can not be used on active mud system since it will shesr drill solids and barite,these solids will also damage pump very quickly.