High Grade Pearl Nickel 6 Inch 7 Inch 8 Inch Diagonal Pliers

-

Transport Package:

-

Carton

-

Origin:

-

Jiangsu China

-

Type:

-

Needle Nose Pliers

-

Material:

-

Chrome Vanadium Steel

-

Size:

-

Common

-

Handle Color:

-

Colorful

- Product Details

- {{item.text}}

Quick Details

-

Handle Material:

-

TPR

-

Size:

-

6 Inch 8 Inch 7 Inch

-

Output:

-

10000Pcs/Week

-

Export Port:

-

Shangahai,Ningbo

-

Payment:

-

L/C T/T Western Union Paypal Money Gram

-

Model NO:

-

HLT-QZ-03-02

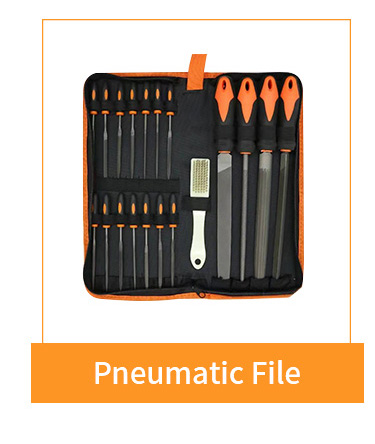

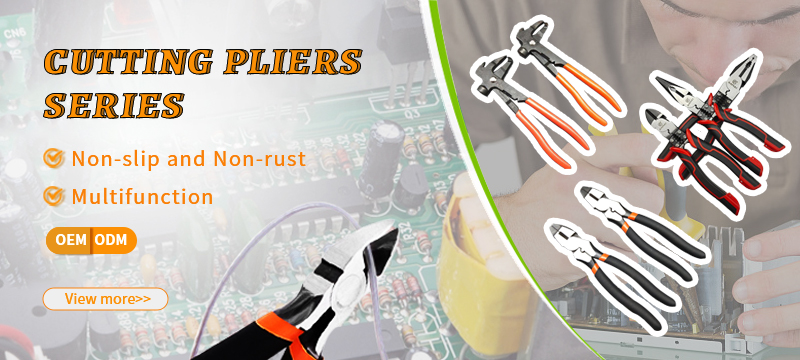

Cutting Pliers Description

Pliers are a hand tool used for clamping, fixing work or twisting, bending, and cutting wires. There are many types of pliers, and the common types are needle-nose pliers, snap ring pliers, cobra pliers, aviation scissors, etc. The nipper pliers body material is chrome vanadium steel, which is highly wear-resistant, durable, and cuts smoothly. The blade can be processed by high-temperature quenching, electropolishing, sandblasting, painting, etc. It is practical and beautiful, and the blade is tough and sharp, not easy to rust. Ergonomically designed, comfortable to hold, with PVC handle and TPR handle, the rubberized treatment process is not easy to slip and sweat, suitable for long-term work, simple and worry-free. Thickened pliers head design, strong shearing force. All parts are tightly connected, not easy to damage, no need to worry about violent use. Bestsuppliers provides tool pliers of various material types, you can contact us at any time to choose the style and quantity you need.

Cutting Pliers Application

The needle nose cutting pliers are essential hand tools for small space operation. which are used in different workers, they can be used by cabinetmakers, shopkeepers,. builders, electricians, construction workers and etc. THE pliers pinch together to cut wires , wood , nails, and anything you want to cut, the cutting pliers are extremely useful in fence building for cutting and twisting the wire , and also for agricultural use in the plant trimming.

Cutting Pliers Production Process

The Pliers production process involve as below:

1.Forging

Forging is the first step and also most important process that decide the pliers final quality ,

2.Drilling

The metal will undergo machining work to form into the rough shape of final product. A small eye will be drilled to fix the pliers. The drilling process will directly affect the coordination of the whole wire cutter , so our cooperating manufacturers will make proper adjustment of individual machine in order to make the high quality products.

3.Rough Scraping

Producing roughly form a metal casting into the shape of a plier via machine.

4.Forming

Gradually form the appearance of pliers

5.Fine scraping

Scraping the surface of pliers to make it more refines

6.Assembly

The palstic handles are added over the top of metal lever

7.Crating blade

Crating a blade from the original metal casting head according to technical specifications

7.Precise drilling

Drill an eye desirable for rivet stamping

8.Riveting

Stamping rivets make cutter stable and durable

9.Grinding

Grinding the surface of the pliers with grinding wheels to remover burrs and creat a polished finish.

10.Quencing

By quencing the pliers, the pliers will be cooled rapid and reach the hardness and strength desired .

11.Blading sharpening

Blade sharpening is the process of sharpening the cutting edges of a blade by grinding or honing it. This process can decide the final cutting sharpness, which is very important for pliers .

12.Polishing

In this process, workers will polish products carefully .even though this process will not affect the product function , it can help create a good appearance for attracting customer to use it.therefor it’s still very important for sale.

Product Category

Company Profile

If you are interested in our products,Please feel free to contact us!

FAQ

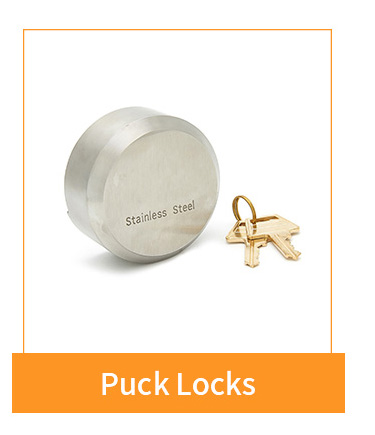

1.What types of hardware, tools, and locks do you supply?

Answer: We provide a diverse range of hardware and tools, including a variety of locks such as padlocks, door locks, and specialty locks. Our tools cover both hand tools and power tools for various applications.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to evaluate the quality, durability, and functionality of our hardware, tools, and locks before committing to a larger order.

3.What is the minimum order quantity (MOQ) for your products?

Answer: The MOQ varies depending on the type of product. Please contact our sales team for specific information about MOQs for locks, tools, or other hardware.

4.How do you ensure the quality of your tools and hardware?

Answer: We implement stringent quality control measures at every stage of production to ensure that our locks and hardware meet the highest standards. Our team conducts thorough inspections and testing.