Wafer Type Semi Ball Valve for Molten Salt Dissolving System

Min. Order: 1 Piece

-

Transport Package:

-

Polywood Case

-

Specification:

-

DN50~DN500

-

Trademark:

-

Quanshun

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Zhengzhou China

-

Media:

-

Water

-

Material:

-

Stainless Steel

-

Connection Form:

-

Other

-

Driving Mode:

-

Manual

-

Nominal Pressure:

-

ANSI CLASS 150-900

-

Channel:

-

Straight Through Type

-

Structure:

-

Fixed Ball Valve

-

Type:

-

Fixed Ball Valve

-

Function:

-

Other

-

Temperature:

-

Normal Temperature

-

Application:

-

Industrial Usage

-

Payment:

-

L/C T/T

-

Export Port:

-

QINGDAO , SHANGHAI, TIANJING

-

Output:

-

5000pieces/year

-

Model NO:

-

BQ377Y

Quick Details

Wafer Type Semi Ball Valve for Molten Salt Dissolving System are a kind of semi ball valve designed for molten salt dissolving system foa alumina refinery .

The continuous working temperature of the valve is 350ºC, and the max instant temperature cal reach to 450ºC,applicable for medium of salt liquid - KNO3, NaNO3, NaNO2 mixture. According to the working condition, the structure is designed as good flow capacity and a linear rotary valve structure.The valve cavity is designed as streamline to reduce the flow resistant,connection of the internal parts are solid and reliable, all moving and sealing parts are all designed for anti-scaling.

In order to short the time of installation and removal, the valve and the pipe flange are connected by a four holes lug.

Because of the offset between the valve flow channel and center line of the valve, the valve stem has "Cam effect" to make sure there is no wear between the ball sealing face and the valve seat sealing face during the opening and closing of the valve, and realizes crush seal to improve the valve working life and guarantee the long time sealing performance. Due to the valve seat be 360°adjusted in the radial direction and can be micro adjusted in axial direction by compressing the gasket. The sealing performance is easy to be guaranteed. And an antifriction gaskets is installed between the ball and valve body to make the ball to be adjusted up and down and also effectively guarantee the good concentricity between the valve seat and ball to make the valve life to be longer.Otherwise,the valve stem and the ball is connected with high position accuracy and big transfer torque by a rectangular spline.

In order to guarantee the working life, the valve body material is selected with ASTM A216WCB and the carbon content is controlled less than 0.23 to improve the corrosion resistance .

Materials of the ball and seat is selected with ASTM A182 316 with hard alloy coatings and whole surface hardening treatment to improve the abrasion -resistance and corrosion resistance.

Material of the valve stem is selected with precipitation-hardening stainless steel 17-7PH with high strength and surface hardness is higher than the normal stainless steel and the anti-corrosion performance is excellent.

Material of packing and gasket is selected with material of heat resistant and non-graphite of high density and High resilient rate to avoid the chemical reaction with the medium and threat to the safety.

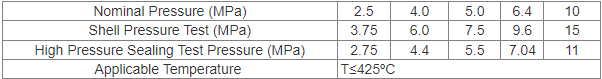

Main Technical Parameters

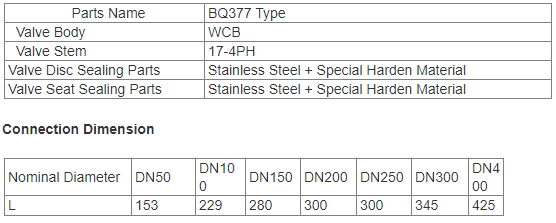

Main Parts and Material