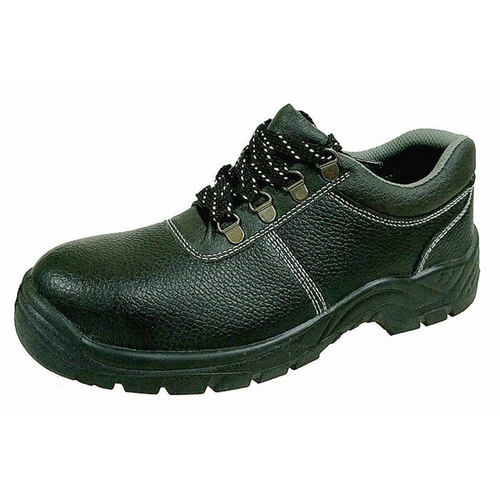

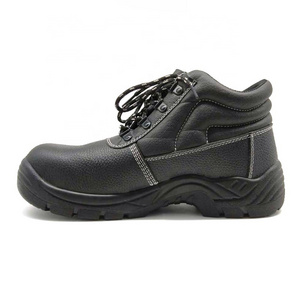

Steel Toe Safety Unisex Cheap Price Industrial Waterproof Leather Work Boots For Men

-

Material:

-

Fabric Custom

-

Feature:

-

Slip-Resistant Puncture-Resistant Waterproof Anti-Static Insulative Custom

-

Outsole Material:

-

PU

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Insole Material:

-

EVA

-

Upper Material:

-

Custom

-

Waterproof:

-

Waterproof Custom

-

Acid and Alkali Resistant:

-

Acid and Alkali Resistant Custom

-

Lining Material:

-

Mesh

-

Hand Made:

-

Hand Made Not Handmade Custom

-

Gender:

-

Unisex

-

Payment:

-

L/C T/T Western Union Paypal Money Gram

-

Export Port:

-

Ningbo

-

Output:

-

10000piece/month

Quick Details

Safety Shoes For Men Description

Safety work shoes are special shoes designed for people working in specific working place, such as construction site, factory, where workers are exposed to the danger of high falling objects that may get feet injured. In this case, a safety work shoe can effectively keep worker’s feet safe from heavy or sharp objects while working in the factory, as this special kind of shoe is durable and reinforced with steel in the toe.

The safety work boots are mainly made of steel, aluminium and plastic caps. The steel made safety shoes are generally with steel toes, but now a lot of safety shoes are also made with carbon fiber, composite material or aluminium alloy safety toes. Both of aluminium alloy toe and composite materials toes shoes provide with the same protection level like old steel toes shoes.

Safety Shoes For Men Detailed Photos

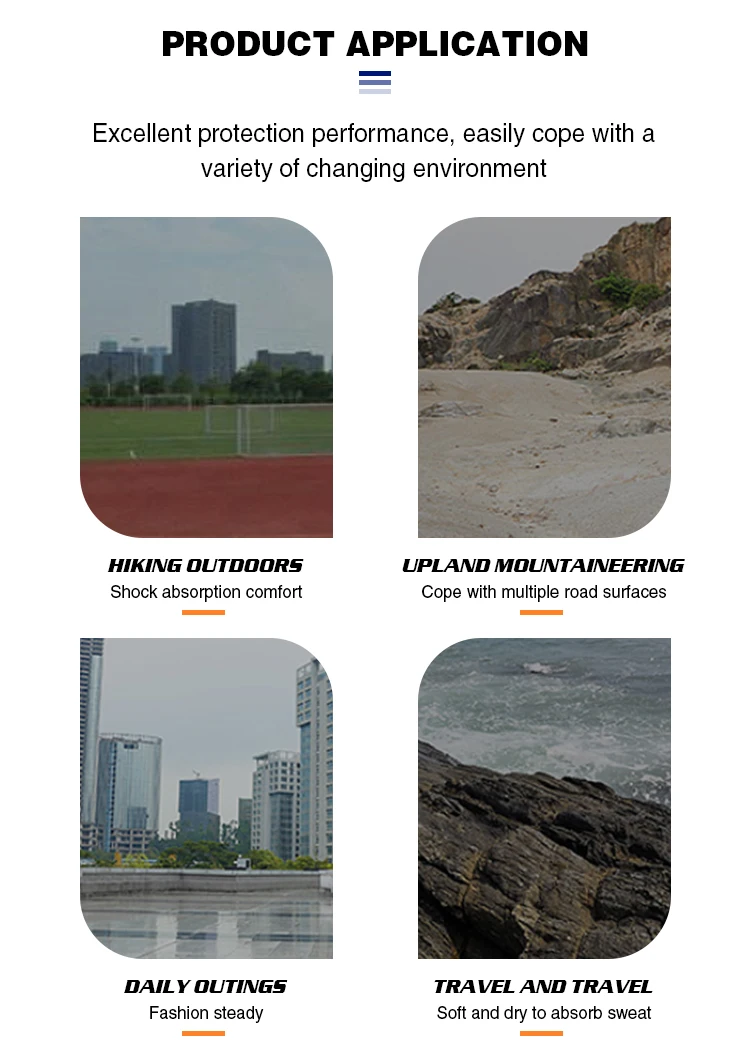

Safety Shoes For Men Application

Safety work shoes for construction industry:

The construction industry requires safety work shoes that provide enhanced protection to guarantee both protection and comfort, these safety shoes must be heat-cold resistant under extreme weather.

Safety boots for foundry industry:

The outsoles are rubber nitrile made for better resistance to the heat, the leathers are thicker thicker than normal shoes, and also with fire proof stitching.

Safety boots for chemical industry:

The safety shoes must have protection against chemicals, they should be highly resistant to certain substance.

Safety work shoes for welders:

The safety shoes have to be anti-adhesive to liquid metal as welding will produce the liquid metal that may attach to the shoes.

Factory Information

Step 1: Cutting the safety shoe parts

The workers place the leather or synthetic materials on the automatic cut machine to die cut sections of safety shoe vamp parts. The machine will cut through leather or synthetic materials depending on what materials are used to make the shoe, in this process, factory will use dies in different sizes and also different designs to form into the patterns.

Step 2: Sewing the safety shoe parts together

After you have already the patterns, then the sewing machine is used to stitch these cut pieces together to make safety upper vamps. Then the toe area is prepared, in this process the metal hooks or eyelets are attached by machine.

Step 3: Shaping the safety shoe

Firstly the protective midsole will be attached as required. Then workers will attach the mold or shoe last, the last plays an important role in shaping the shoe into the form required. Then the shoe safety toe cap needs to be installed inside, the shoe cap is usually made of steel, composite materials.

Step 4: Making safety shoe sole

The sole needs to be prepared by using required method. With the prepared sole, workers needs to attach it to the shoe upper. Generally the sole is mold injected, then sewn, or glued to the upper. Then remove the excess materials to make it a prefect finished shoe.

Step 5: Safety shoe quqlity control

Final finished shoes will be checked for quality using specific measuring instruments. Then the shoes are packed into boxes, and get ready for shipping to customer

Our Service

| Pre-sales Service 1.Keep in touch with you closely, keep you posted for all the line of your goods. 2.Do our best to cooperate with you from the enquiry to order to the shipment arrangement. |

After-Sales Service 1.Supply competitive price and heart to heart service for our customer. |  |

Shipping&Payment

FAQ

1.What types of building materials do you supply?

Answer: We offer a wide range of building materials, including but not limited to steel, glass, tiles, roofing materials,and insulation.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to assess the quality, specifications, and suitability of our building materials for their projects.

3.What is the minimum order quantity (MOQ) for your building materials?

Answer: The MOQ varies depending on the type of building material and specific product. Please contact our sales team for detailed information about MOQs.

4.Are your building materials compliant with international standards?

Answer: Yes, our building materials comply with relevant international standards and certifications. We can provide documentation upon request.

5.Can you customize building materials to meet specific project requirements?

Answer: Yes, we offer customization options for certain building materials. Contact our sales team to discuss your specific requirements and customization possibilities.

6.What is your lead time for production and delivery?

Answer: Production and delivery times depend on the type and quantity of building materials ordered. We provide estimated timelines upon order confirmation.