F1000 Crosshead Mud Pump Parts Fluid End Crosshead for Oilfield Equipment

-

Transport Package:

-

By wooden box

-

Specification:

-

F1000

-

Trademark:

-

HTON

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

Certification:

-

ISO 9001:2000 ISO 9001:2008

-

Power Source:

-

Hydraulic Electric

-

Operation Pressure:

-

Atmospheric Pressure Other

-

Material:

-

Alloy Stainless Steel Cast Aluminum Cast Steel Other

-

Type:

-

Other

-

Payment:

-

L/C T/T

-

Export Port:

-

Tianjin

-

Output:

-

500000

-

Model NO:

-

F1000

Quick Details

short introduction

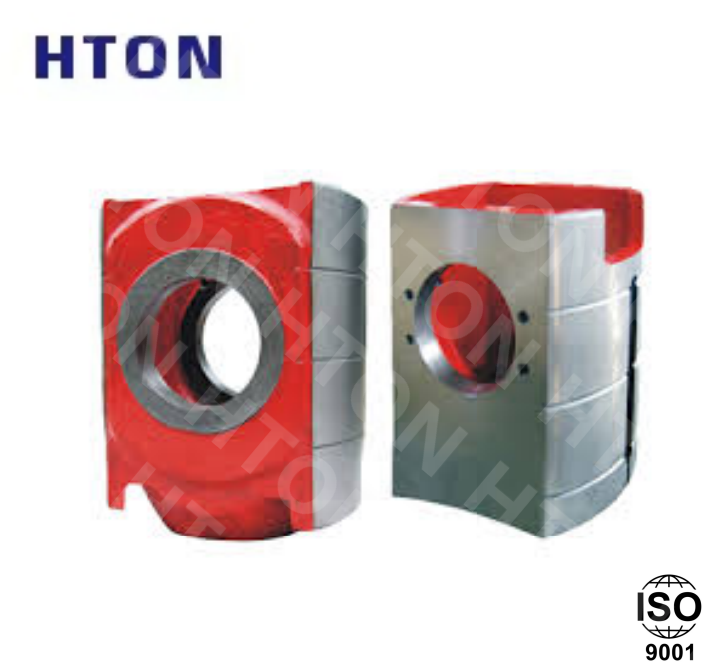

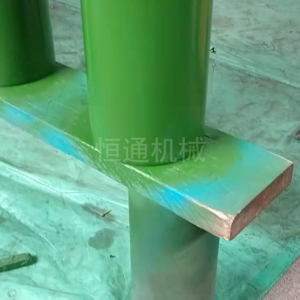

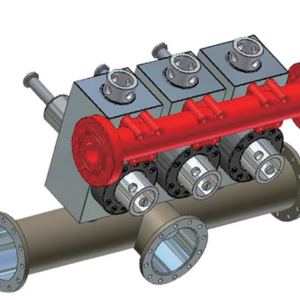

The crosshead is a key part of the power end of the mud pump. When working, the crosshead slides in the upper and lower guide plates, pushing the middle tie rod to transmit power to the hydraulic end. One end of the crosshead fixes the middle tie rod, and the small end of the connecting rod is connected to the cavity through the crosshead pin. The material of the crosshead is ductile iron with a tensile strength greater than 600MPa, which ensures its high strength and wear resistance.

detailed photo

Importance of the Crosshead in a Mud Pump:

Transmission of Motion: The primary function of the crosshead is to transfer and convert the rotary motion of the crankshaft into a reciprocating linear motion. This motion is used to drive the piston of the mud pump.

Protection: The crosshead ensures that the rotary motion from the crankshaft and the associated lubricants do not contaminate the linear system of the piston and the drilling fluid. This is crucial, as contamination could cause damage to the piston, the mud pump, and even the well being drilled

Guidance: It provides guidance and alignment to the piston rod, ensuring straight and smooth movement. This is essential for the efficient functioning of the mud pump and for minimizing wear and tear.

Absorption of Side Loads: The crosshead absorbs any side loads or off-axis forces that might arise, ensuring that the piston moves straight and true. This is vital for the efficient operation of the mud pump and for extending the life of the pump components.

Crosshead •Photo used for illustrative purposes

Parts that Make Up the Crosshead:

Crosshead Body: This is the main component that provides the sliding mechanism to convert rotary to linear motion.

Crosshead Pin: This pin connects the crosshead to the connecting rod, enabling the transmission of motion.

Crosshead Guides: These are guides, often made of metal plates, that ensure the straight-line movement of the crosshead.

Crosshead Slipper: It's an additional guiding component that might be present in some designs to stabilize the crosshead's movement.

Lubrication System: Most crossheads come with their lubrication channels or mechanisms to ensure minimal wear and tear due to friction.

Characteristics of the Crosshead:

Robust Design: Given the high pressures and forces involved in mud pumping, crossheads are designed to be sturdy and to handle these extreme conditions.

Tight Tolerances: Precision is crucial in drilling operations. Thus, crossheads are manufactured with tight tolerances to ensure efficient operation and minimize unwanted sideways movement.

Wear-resistant: Since they are continuously in motion during drilling operations, crossheads are typically made of wear-resistant materials or are designed with replaceable wear surfaces.

Lubrication: Effective lubrication mechanisms are integrated to minimize friction, reduce wear, and extend the lifespan of the crosshead and associated components.

Ease of Maintenance: Many modern crossheads are designed for easy maintenance and replacement, ensuring minimal downtime for the drilling rig.

FAQ

How to order?

Please send us your inquiry with detail item description or with Model number.

If there is no packing demand we take it as our regular exported standard packing.

We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

You send ud your detail requirement, we provide quotation to you.

Can I expect a quality products?

All the production and processing are strictly according to ISO 9001:2008 and API standard. At the same time, mature production technology ensuring the quality satisfy international request. We also welcome the third party inspection, such as BV, SGS and TUV.

The information you may like to know before Payment:

1. Methods of Payment:

T/T (Telegraphic Transfer) or L/C at sight

2. Shipping way

Sample order: we suggest Courier express like DHL/UPS/TNT/FEDEX or by air

Bulk order: we suggest by air or by sea.

3. Quality Control

We have our own experienced QC.

There will be strict inspection and testing for every order before shipping out.