A complete guide of truck tyre selection: what are different types of truck tyres

Introduction:

Tires are key parts of vehicles because they affect vehicle performance and fuel economy, tread patterns can affect the performance and handling of your vehicle, especially for trucks and heavy conveyance. The job of a truck driver is not easy because they are constantly on the move. They drive in all weather conditions and terrains to ensure timely delivery. Therefore, good truck tires are an important part of trucks. They need to not only ensure the safety of the driver but also provide a smooth and comfortable driving experience. We will discuss the types of tires with different tread patterns, how to choose the right truck tires, how long a truck tire can last, and which vehicles truck tires are suitable for in our blog. At Bestsuppliers.com, you'll find a diverse range of truck tire options to suit your specific requirements.

Three Types of Truck Tyres:

1. Highway Truck Tires (H/T Tires):

H/T tires are made for expressways. The tread pattern and structure of them are more similar to those of car tires. The tread pattern is dense and the wall is relatively soft. Since it does not take into account the off-road needs, its ride comfort will be better than other professional tires. Whether it is shock absorption, or sound insulation, road control performance is better while providing longevity. These tires typically offer better gas mileage than other types, and with skyrocketing gas prices, H/T tires can be an economical choice. For people who do not have off-road needs, mainly driving in the city and occasionally walking on some light unpaved roads, H/T tires can be chosen.

2. All-terrain Truck Tires (A/T tires):

All-terrain truck tires are suitable for off-road or rough conditions. When not driving on paved surfaces, these tires feature a stronger tread pattern for increased traction. Compared with highway truck tires, A/T tires have deeper pattern depth, wider pattern grooves, and larger pattern blocks. But on paved surfaces, A/T tires are less comfortable and have less handling, and they wear out faster. So the A/T tire is suitable for people with some off-road needs.

3. Max-Traction or Mud-Terrain Truck Tires (M/T Tires):

These tires are suitable for rocky and soft terrains. Since tires need optimal traction on rugged terrains like mud and slippery rocks, these truck tires are typically larger while featuring tread lugs. M/T tires typically use softer compounds that can flex and “grab” onto rocky surfaces, providing increased traction on bumpy trails. However, these softer compounds also cause M/T tires to wear out more quickly when used at highway speeds. These tires offer good brake performance, wear resistance, and increased resistance to cuts. They may have increased noise levels and a shorter lifespan than other tires. So M/T tires are suitable for extreme off-road driving.

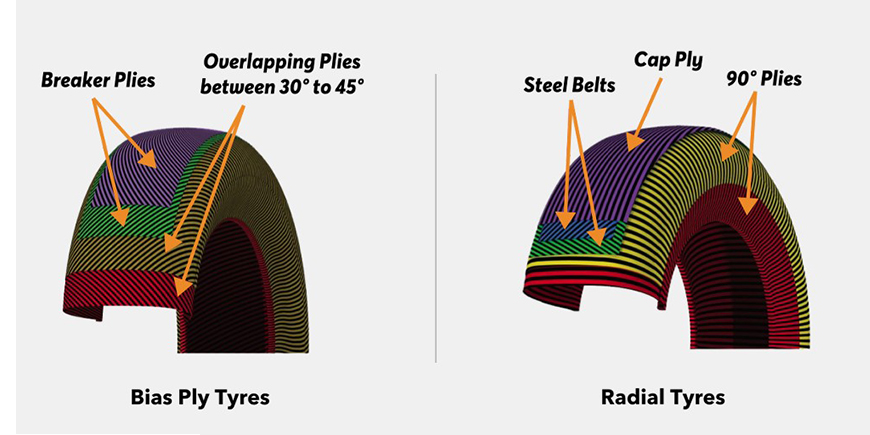

What Are Bias Ply Tires and Radial Tyres?

The main difference between bias and radial tires is the belting structure. The cord material is also different, resulting in the functional performance of bias tire and radial tire changes. Bias tires are nylon tires and radial tires are steel tires.

About Bias Ply Tyres:

Advantages:

The sturdy construction and tread pattern make it more suitable for off-road, with more flexible sidewalls that provide better grip on irregular surfaces, making it ideal for off-road vehicles. They are usually cheaper than radial tires. Provides a more stable ride and is better able to withstand heavy loads.

Disadvantages:

Tread wears faster due to higher traction. High rolling resistance can affect fuel economy. The rollover effect can cause a loss of traction in a turn.

About Radial Tyres:

Advantages:

Radial tires are the most commonly used. It has an up-and-down vertical side wall made of a single layer of wire rope cord fabric at a 90-degree Angle to the center line of the tire. It is smoother and more comfortable to drive than bias tires. Radial tires operate at lower temperatures at high speeds and under load, are more fuel efficient, have a longer service life, are more puncture resistant, and can better cope with high speeds. Radial tires have a better grip on the road, providing better handling and stability.

Disadvantages:

Sometimes, the steel strip structure can affect the ride quality. Curb impacts can cause sidewall damage. Harder tread increases tire noise. They are usually more expensive than bias-ply tires.

What tread depth should truck tires be replaced?

When it comes to replacing truck tires, one important factor to consider is the thread depth. The thread depth of a tire is crucial for maintaining traction and ensuring safety on the road.

The general rule of thumb is that truck tires should be replaced when the tread depth reaches 4/32 of an inch. This is the minimum depth recommended by most experts to ensure optimal performance and safety.

When the tire tread depth falls below 4/32 inches, the tire's traction and water evacuation capabilities significantly decrease, increasing the risk of skidding on wet or slippery roads. Additionally, insufficient tread depth can affect tire wear resistance, shortening the tire's lifespan.

How long do truck tires last

Truck tires typically last between 30,000 to 80,000 miles, depending on factors such as road conditions, load weight, driving habits, and regular maintenance. However, some truck operators may replace tires sooner to ensure vehicle safety and performance.

It is important to note that regular inspections of tire wear, pressure, and overall condition are crucial for extending the lifespan of truck tires. Timely replacement of severely worn or aged tires can reduce the risk of accidents and improve driving efficiency.

Four Factors to Consider When Choosing Commercial Truck Tires:

1. Trucking Routes:

It is vital to know the condition of the road on which the truck is traveling. Do they take the highway or the dirt road? Does it often rain on these routes, or is it usually dry? Is the area usually warm or cold? These factors affect the performance of the tire, so using the right type of tire can avoid future problems and reduce operating costs.

2. Vehicle Type and Cargo Load:

Pickup trucks and utility vehicles typically use passenger car radial tires (PCR), while heavier vehicles such as vans use light truck radial tires (LTRS). Even heavier vehicles use truck bus radial tires (TBR) or Heavy equipment tires (HET).

3. Tire Material:

The rubber in tires varies in hardness. Tires made of softer rubber usually have better traction and a smoother ride on the road. However, soft rubber also has lower fuel efficiency and durability than hard rubber tires. Hard tires are more durable but have less traction.

4. Service life:

Please consider the service life of the product before purchase. High-quality tires are an investment, so you want to make sure they last for the entire expected duration.

Application Vehicle:

1. Bulldozer:

They’re used to clear construction sites of obstacles. In addition, they can be used to dig ditches, do agricultural work, and take part in military activities.

2. Front Loader:

They are used to transport building materials, such as digging tools, pipes, metal rods, and bricks. In addition, they are used to sweep loose materials from the ground to clear obstructions at construction sites.

3. Dump Truck:

Dump trucks are used to dump debris and deliver extra materials to construction sites, factories, etc.

4. Backhoe:

Excavators are also engineering vehicles used to move debris. They can be driven over rough terrain and used to clean construction sites.

5. Compactor:

Compactors compact soil on construction sites to prevent the soil structure from being damaged.

6. Crane:

Cranes are used to lift and lower heavy objects beyond human capacity. Among other things, they can move materials horizontally.

In Conclusion:

Are you looking for quality tires? Bestsuppliers offers a wide array of tires for various purposes—from passenger cars and motorcycles light trucks to heavy equipment vehicles. We will deliver at an affordable price.