Categories

-

Tools & Hardware

- Drilling Tools

- Drill Bit

- Drill Collar

- Drill Rod

- Drill Sleeves

- Drilling Jar

- Drilling Stabilizer

- Other Drilling Tools

- Fastener & Fittings

- Nail

- Screw

- Rivet

- Tapping Screws

- Glass Holder

- Circlip

- Combination & Joint Fittings

- Pin

- Stud

- Wire Thread Insert

- Wood Screws

- Other Fastener & Fitting

- Flanges

- Bolts

- Nuts

- Anchor

- Gasket & Washer

- Hand Tools

- Brush

- Hammer

- Tape Measures

- Other Hand Tools

- Chisel & Punch

- Crowbar

- Hand Tool Set

- Tag Gun

- Tap & Die

- Axe

- Screwdriver

- Grease Gun

- Files

- Wrench

- Nail Guns

- Pliers

- Nail Puller

- Riveter

- Sickle

- Levels

- Saw

- Abrasive & Grinding

- Grinding Wheel

- Emery Cloth

- Abrasive Brush

- Abrasive Cloth & Mesh

- Abrasive Grains

- Blasting Media

- Flap Disc

- Grinding Ball

- Grinding Beads

- Grinding Disc

- Grinding Head

- Grinding Powder

- Grinding Rods

- Grinding Segment

- Non-Woven Abrasives

- Polishing Pad

- Sanding Belt

- Sharpening Stone

- Superhard Materials

- Other Abrasive & Grinding Tools

- Abrasive Tools

- Sandpaper

- Grinder

- Diamond Tools

- Diamond Cutter

- Diamond Saw Blade

- Diamond Drilling Tools

- Diamond Fickert

- Diamond Grinding Wheel

- Diamond Router Bit

- Diamond Wire Saw

- Door & Window Hardware

- Window Handle

- Door Stop

- Door Viewer

- Window Screening

- Door & Window Hinges

- Curtain Rod

- Curtain Rod Accessories

- Curtain Track

- Curtain Track Fittings

- Door & Window Hook

- Door & Window Roller

- Door & Window Slide

- Door Curtains

- Patch Fitting

- Other Door & Window Hardware

- Door Handle

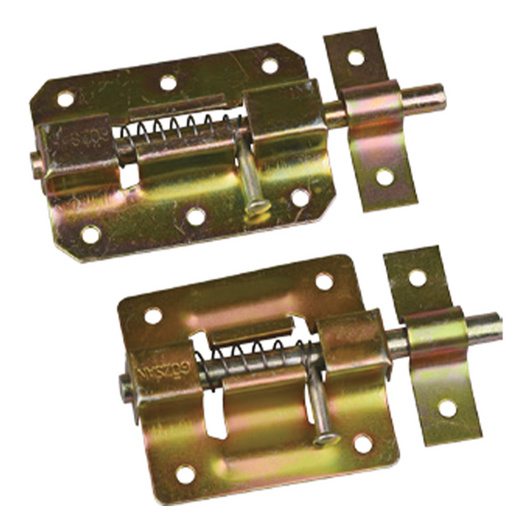

- Door & Window Bolt

- Door Closer

- Door Opener

- Furniture Hardware

- Other Furniture Hardware

- Bed Hook

- Drawer Slides

- Furniture Handles & Pulls

- Furniture Hinges

- Furniture Bolt

- Swivel Plate

- Wardrobe Tube

- Building Hardware

- Other Building Hardware

- Hydraulic Parts

- Hydraulic Accumulator

- Hydraulic Cylinder

- Hydraulic Fittings

- Hydraulic Motor

- Hydraulic Power Unit

- Hydraulic Pump

- Hydraulic Seal

- Hydraulic Valve

- Other Hydraulic Parts

- Hydraulic Tool

- Lean Pipe & Pipe Rack System

- Machine Hardware

- Other Machine Hardware

- Tools & Hardware Stocks

- Other Tools & Hardware

- Power Tools

- Demolition Hammer

- Electric Planer

- Electric Screwdriver

- Electric Trimmer

- Electric Wrench

- Heat Gun

- Hot Knife

- Pipe Threading Machine

- Power Tool Accessories

- Power Tool Set

- Rotary Hammer

- Sander

- Wall Chaser

- Other Power Tools

- Other Power Tool Accessories

- Hot Melt Glue Guns

- Power Hammer Drills

- Electric Drill

- Electric Saw

- Home Hardware

- Knife

- Other Home Hardware

- Scissors

- Pneumatic Tools

- Hardware Accessories

- Hasp & Staples

- Lid Stay

- Roller

- Clamps

- Turnbuckle

- Shackles

- Other Hardware Accessories

- Spring

- Hooks

- Brackets

- Chain

- Wheel & Caster

- Industrial Caster

- Furniture Casters

- Medical Caster

- Dustbin Wheel

- Supermarket Caster

- Wheel & Caster Accessories

- Other Wheels & Casters

-

Apparel & Accessories

- Children's Clothing

- Girl's Clothing

- Boy's Clothing

- Baby Clothing

- Toddler Clothing

- Family Matching Outfits

- Men's Clothing

- Men's Hoodies & Sweatshirts

- Men's T-Shirts

- Plus Size Men's Clothing

- Men's Jackets

- Men's Shirts

- Men's Shorts

- Men's Pants & Trousers

- Men's Polo Shirts

- Men's Sets

- Men's Suits & Blazer

- Men's Tank Tops

- Men's Jeans

- Men's Sweaters

- Men's Vests & Waistcoats

- Men's Down Coats

- Men's Coats

- Men's Sleepwear

- Men's Leggings

- Women's Clothing

- Jumpsuits & Playsuits & Bodysuits

- Maternity Clothes

- Women's Shorts

- Women's Blouses & Shirts

- Women's Coats

- Women's Hoodies & Sweatshirts

- Women's Jackets

- Women's Jeans

- Women's Pants & Trousers

- Women's Sets

- Women's Suits & Tuxedo

- Women's Sweaters

- Women's T-Shirts

- Women's Trench Coats

- Women's Underwear

- Womens Skirts

- Womens Dresses

- Plus Size Women's Clothing

- Women's Jumpsuits & Playsuits

- Women's Skirts

- Women's Sleepwear

- Women's Denim

- Women's Tank Tops

- Women's Leggings

- Women's Shorts

- Women's Polo Shirts

- Novelty & Special Use

- Hospital Uniforms

- Training Dancewear

- Performance Wear

- Reenactment Attire

- Restaurant & Bar Uniforms

- Mascot

- Anime Costumes

- Hotel Uniforms

- Sexy Costumes

- School Uniforms

- Other Uniforms

- Promotion Uniforms

- Fireman Uniforms

- Camouflage

- Guard Uniforms

- Airline Uniforms

- Bank Uniforms

- Costume Props

- Game Costumes

- TV & Movie Costumes

- Zentai / Catsuit

- Other Costumes

- Scarves & Shawls

- Silk Scarves

- Other Scarves & Shawls

- Square Scarf & Handkerchiefs

- Knitted Shawls

- Fur Scarves

- Fur Shawls

- Knitted Scarves

- Silk Shawls

- Sun Protection Veil

- Ties & Accessories

- Polyester Ties

- Other Ties & Accessories

- Silk Ties

- Bow Ties

- Cravats

- Tie Clips & Tie Bars & Tie Pins

- False Collar Accessories

- Knitting Apparel

- Clothing Accessories

- Trimmings

- Other Garment Accessories

- Ribbons

- Shoulder Pads

- Tag Guns

- Knitting Rib

- Braid

- Boning

- Garment Hooks

- Mannequins

- Underwear Accessories

- Sewing Needles

- Sewing Threads

- Tailor's Scissors

- Other Sewing Supplies

- Button

- Apparel Beads

- Apparel Clip

- Apparel Eyelet

- Buckle & Hook & Loop

- Clothing Flower

- Clothing Pads

- Clothing Rivet

- Clothing Stopper

- Cuff Links

- Fashion Chains

- Fur Collar

- Interlining & Lining

- Neckline

- Patch

- Rhinestone

- Rib Cuff

- Rope & Woven Tape

- Sequins

- Webbing

- Zipper & Slider

- Other Clothing Accessories

- Gloves & Mittens

- Work & Labor Gloves

- Cleaning Gloves

- Etiquette Gloves

- Oven Gloves

- Sports Gloves

- Warm Gloves

- Wedding Gloves

- Work & Safety Gloves

- Other Gloves & Mittens

- Safety & Protective Apparel

- Isolation Gown

- Protective Clothing

- Reflective Safety Clothing

- Chemical Protective Clothing

- Fireproof Suit

- Flame Retardant Clothing

- Stab-resistant Clothing

- Other Safety & Protective Apparels

- Bullet Proof Clothing

- Shoes & Accessories

- Functional Shoes

- Outdoor Shoes

- Slippers

- Women Shoes

- Shoe Parts & Accessories

- Athletic & Sports Shoes

- Sportswear

- Swimwear & Beachwear

- Fitness & Yoga Wear

- Rugby Football Wear

- Soccer Wear

- American Football Wear

- Basketball Wear

- Yoga sets

- Bikinis & Beachwear

- Baseball & Softball Wear

- Sports Bras

- Cycling Arm Sleeves

- Gym Fitness Sets

- E-sports Wear

- Pickleball Wear

- Horse riding wear

- Golf Clothing

- Gymnastics Clothing

- Cheerleading Uniforms

- Hunting Wear

- Volleyball Wear

- Ice Hockey Wear

- Tennis Wear

- Fishing Wear

- Martial Arts Wear

- Motorcycle & Auto Racing Wear

- Ski & Snow Wear

- Wetsuits

- Rash Guard

- Other Sportswear

- Jogging Wear

- Running Pants&Shorts

- Training Wear

- Tracksuits

- Running T-shirts&Tops

- Running Tights

- Cycling Jerseys

- Cycling Sets

- Bib Shorts&Tights

- Yoga Leggings

- Hoodies&Sweatshirts

- Insulated & Down

- Outdoor Jackets

- Outdoor Shirts&Tops

- Outdoor Pants

- Racing Swimsuits

- Fitness Swimwear

- Swimsuit cover ups

- Board shorts&Swim trunks

- Wedding Apparel & Accessories

- Wedding Dresses

- Flower Girls' Dresses

- Hat & Cap

- Other Hats & Caps

- Sports Caps

- Leisure Caps

- Warm Caps

- Work Caps

- Sun Cap

- Belt & Accessories

- Belt Parts & Accessories

- Fabric Belt

- Belt Chains

- Leather Belt

- PVC Belts

- Metal Belt

- Tummy Belts

- PU Belt

- Beaded Belts

- Plastic Belt

- Chain Belts

- Suspenders

- Knitted Belts

- Other Belts

- Shell Belts

- Other Belt Accessories

- Sock & Stocking

- Kids Shoes

- Children's Shoes

- Baby Shoes

- Other Kids' Shoes

- Apparel Stocks

- Couples Clothes

- Down & Winter Apparel

- Dress Hat

- Bowler & Deby Hat

- Fedora

- Formal Hat

- Other Dress Hat

- Dresses

- Dust Coat

- Ethnic & Folk Apparel

- Modest Swimwear

- Traditional Muslim Clothing&Accessories

- Traditional Chinese Clothing

- Asia & Pacific Islands Clothing

- Modest Dress

- Modest Coats

- Modest Sets

- African Clothing

- Indian & Pakistani Clothing

- Modest Sportswear

- American Clothing

- Other Regional Clothing

- European Clothing

- Modest Hoodies & Sweatshirts

- Modest Evening Dress

- Modest Trench Coats

- Modest Blouses & Shirts

- Modest Jackets

- Modest Sweaters

- Modest Jumpsuits & Playsuits & Bodysuits

- Modest Wedding Dress

- Modest Pants

- Modest Underwear

- Ethnic Scarves & Shawls

- Ethnic Bandanas

- Other Ethnic Accessories

- Family Clothing

- Jacket

- Jeans

- Leather & Fur

- Leisure Apparel

- Mannequin

- Military Style Apparel

- Necktie & Bow Tie

- Outer Wear

- Pajamas & Bathrobe

- Pants & Trousers

- Scarf & Warm

- Bandana & Headband & Cravat

- Scarf

- Shawl

- Warm Set

- Shirt & Blouse

- Shoes

- Boots

- Dance Shoes

- Leather Shoes

- Leisure & Comfort Shoes

- Men's Shoes

- Sandals

- Shoes Parts & Accessories

- Used Shoes

- Work & Safety Shoes

- Silk Apparel

- Skirt

- Specialized Cap

- Birthday Party Hat

- Cosplay Hat

- Festive Hat & Party Cap

- Santa's Hat

- Wedding Hat

- Other Specialized Cap

- Suit

- Sweater

- Swimwear

- T-Shirt

- Children's T-Shirts

- Tank Top

- Theatrical Costume

- Underwear

- Bra

- Camisole & Lingerie

- Sexy Lingerie

- Shapers

- Underpants

- Underwear Set

- Other Underwear

- Uniform & Work Clothes

- Uniform

- Work Clothes

- Used Clothes

- Vest & Waistcoat

- Wedding Dresses & Ceremonial Clothing

- Bridesmaid Dresses

- Celebrity Dresses

- Cocktail Dresses

- Flower Girl Dresses

- Graduation Dresses

- Homecoming Dresses

- Men's Dress

- Mother of the Bride Dress

- Prom Dresses

- Quinceanera Dresses

- Wedding Accessories

- Other Ceremonial Clothing

- Other Apparel

-

Packaging & Printing

- Packing Machinery

- Packing Machinery Parts

- Packing Line

- Multi-Function Packing Machine

- Sealing Machine

- Laminating Machine

- Filling Machine

- Wrapping Machine

- Strapping Machine

- Palletizer

- Coding Machine

- Heat Shrink Packaging Machine

- Gluing Machine

- Labeling Machine

- Pressure Filling Machine

- Vacuum Packing Machine

- Vacuum Filling Machine

- Case Packer

- Other Packing Machinery

- Package & Conveyance

- Packaging Ropes & Strappings

- Packing Tape

- Body Bag

- Paper Packaging

- Paper Boxes

- Paper Bags

- Plastic Film

- Packaging Paper

- Logistics Packaging

- Packaging Boxes

- Packaging Auxiliary Materials

- Packaging Bags

- Other Packaging & Printing Products

- Paper Cups

- Mailing Bags

- Lids & Bottle Caps & Closers

- Plastic Boxes

- Adhesive Paper & Film

- Metal Foil

- Packaging Labels

- Glass Packaging

- Paper Tube

- Packaging Barrels & Buckets

- Packaging Tubes

- Packaging Tray

- Packaging Bowls

- Packaging Cartons

- Cup Sleeve

- Garment Tag

- Lids, Bottle Caps & Closers

- Edge & Corner Protector

- Slip Sheet

- Protective & Cushioning Material

- Packaging Cans & Jars

- Air Dunnage Bags

- Metal Packaging

- Foam Packaging

- VCI Packaging

- Plastic Preform

- Blister Cards

- Other Package & Conveyance

- Packaging Bottles

- Printing Machinery

- Rotogravure Printing Machine

- Glass Printing Machine

- Color Printing Press

- Textile Printing Machine

- Offset Printing Machine

- Business Card Printing Machine

- Leather Printing Machine

- Bill Printing Machine

- Heat Transfer Equipment

- Flexographic Printer

- Label Printing Machine

- Digital Printing Machine

- Screen Printer

- Plastic Printing Machine

- Heat Press Machine

- Code Printing Machine

- Relief Printing Machine

- Pad Printer

- Printing Machinery Parts

- Other Printing Machinery

- Printing Materials

- White Paperboard

- Photographic Film

- Writing Paper

- Two-Sided Offset Paper

- Transfer Paper

- Special Paper

- Coated Paper

- Newsprint

- Printing Plate

- Printing Mesh

- Printing Inks

- Transfer Film

- Other Printing Materials

- Package & Printing Service

- Label & Sticker Printing

- Disk / CD Replication & Printing

- Textile Printing

- Metal & Tin Glass Printing

- Card Printing

- Book & Magazine Printing

- Plastic Printing

- Calendar Printing

- Brochure Printing

- Paper & Paperboard Printing

- Transfer Printing

- Other Package & Printing Service

- Machinery for Packaging Supplies

- Slitting Machine

- Folder Gluer

- Aluminum Foil Container Production Line

- Window Patching Machine

- Blister Packaging Machine

- Paper Bag Machine

- Carton Machine

- Bag Making Machine

- Other Packaging Machinery

- Tag & Sign

- Metal Tag & Sign

- Nonmetallic Tag & Sign

- Tool Packaging

- Tool Cabinet

- Post-Press Equipment

- Hole Puncher

- Compound Machine

- Die Cutting Machine

- Paper Cutter

- Polishing / Glazing Machine

- Hot Stamping Machine

- Coating Machine

- Pressing Machine

- Embossing Machine

- Folding Machine

- Other Post-Press Equipment

- Pre-Press Equipment

- Proofing Machine / Proofer

- Plate Drying Oven

- Duplicator

- Inkjet System

- Exposure Machine

- Developing Machine

- Prepress Auxiliary Equipment

- Imagesetter

- Plate Machine

- Other Pre-Press Equipment

- Packaging Materials

- Laser Film

- Aluminum Foil

- Krait Paper

- Shrink Film

- Hot Stamping Foil

- Corrugated Paper & Board

- Other Packaging Materials

- Composite Packaging Materials

- Metallized Film

- Cardboard

- Stretch Film

-

Electrical & Electronics

- Power Supply & Distribution

- LED Power Supply

- LED Conversion Kit

- Electric Power Fitting

- Junction Box

- Switching Power Supply

- Switchgear

- Busbar

- Power Distribution Cabinet & Box

- Power Adaptor

- Voltage Regulator

- Other Power Supply & Distribution

- Electrical Adapters

- UPS

- Plug

- Breaker & Protector

- Circuit Breaker

- Fuse

- Fuse Block & Holder

- Arrester

- Earthing System

- Lightning Receiver

- Other Breaker & Protector

- GPS

- GPS Navigator

- GPS Receiver

- GPS Module

- GPS Accessories

- GPS Tracker

- Other GPS

- LED Video Processor

- Semiconductor

- Transmitter

- Differential Pressure Transmitter

- Weight Transmitter

- Current Transmitter

- Voltage Transmitter

- Flow Transmitter

- Temperature & Humidity Transmitter

- Pressure Transmitter

- Liquid Level Transmitter

- Other Transmitters

- Electronic Components & Accessories & Telecommunications

- Cleaning Swab

- Telecommunication & Broadcasting

- Communication Module

- Network Cabinet

- Signal Jammer

- Other Communication Products

- Fiber Optic Equipment

- Communication Cables

- Telecommunication Towers & Accessories

- Telecom Parts

- Communication Antennas

- Telephones & Accessories

- Wireless Infrastructure Equipment

- Enterprise Routers

- Other Telecommunications Products

- Telephone Headsets

- Telecom Power

- Telephone Cords

- VoIP Products

- Repeaters

- Fixed Wireless Terminals

- Corded Telephones

- Enterprise Wireless Access Points

- PBX

- Enterprise Firewalls

- GNSS & GPS Antennas

- Cordless Telephones

- Broadcast Intercom Systems

- WiFi Products

- Telecom Tower

- Emission Transmission Equipment

- Radio & TV Broadcasting

- Call Center Equipment

- Set Top Box

- Front-end Equipment

- Satellite

- Other Telephone Accessories

- Sensor

- Differential Pressure Sensor

- Ultrasonic Sensor

- Current Sensor

- Voltage Sensor

- Load Cell

- Inertial Sensor

- Photoelectric Sensor

- Light Sensor

- Fiber Optic Sensor

- Water Leak Sensor

- Flow Sensor

- Torque Sensor

- Gas Sensor

- Image Sensor

- Displacement Sensor

- Temperature & Humidity Sensor

- Pressure Sensor

- Liquid Level Sensor

- Electric Contact & Materials

- Electromagnetic Equipment

- Electric Motor

- Stepper Motor

- Electric Motor Parts

- AC Motor

- Synchronous Motor

- Micro Motor

- Asynchronous Motor

- DC Motor

- Other Motors

- Circuit Board

- PCBA

- Single-Sided PCB

- Multilayer PCB

- Rigid-Flex PCB

- Rigid PCB

- Breadboard

- FPC

- Double-Sided PCB

- Other Circuit Board

- Speaker & Trumpet & Buzzer

- Electronic Tube & Transistor

- Light Emitting Diode

- Laser Diode

- Switching Diode

- Zener Diode

- Triode

- Rectifier Diode

- Other Electronic Tubes & Transistors

- Integrated Circuit

- Relay & Contactor

- Relay

- Contactor

- Energy Saver

- Tester & Sensors & Detectors

- Audio Sensors

- Sensor Development Tools

- Encoders

- Proximity Sensors

- Motion & Position Sensors

- Optical Sensors

- Temperature Sensors

- Infrared Sensor

- Microwave Motion Sensor

- Other Sensors

- Decoder

- Insulation

- Electronics Stocks

- Connector & Terminals

- PCB Connector

- RF Connector

- Board to Board Connector

- Terminals

- Terminal Blocks

- Fiber Connector

- Slip Ring

- Spacer Support

- Rectangular Connector

- Jack

- Coaxial Connector

- Wire to Board Connector

- Wire to Wire Connector

- Audio & Video Connectors

- Circular Connector

- Alligator Clip

- Other Connectors

- Inverter

- Power Inverter

- Other Inverters

- Sound Module

- Antenna

- Radio

- Passive Components

- Inductor

- Capacitor

- Resistor & Potentiometer

- Signal Filter

- Resonator

- Other Passive Components

- Cable Parts

- Cable End Caps

- Cable Gland

- Cable Clips

- Cable Ties

- Cable Marker

- Patch Panel

- Wiring Duct

- Cable Sleeve

- Tie Mount

- Other Cable Parts

- Oscillator

- Smart Card & Card Reader

- IC Card

- RFID Tag

- RFID Card

- RFID Wristband

- Magnetic Card

- Smart Card Reader

- Other Smart Card

- Specialized Electrical Equipment

- Other Electronics

- Electrode

- Electrical Control System

- Heating & Refrigeration & Temperature Control

- Thermostat & Temperature Controller

- Heating Element

- Heat Pump

- Thermoelectric Cooler Module

- Other Heating & Refrigeration & Temperature Control

- Remote Control

- Variable-Frequency Drive

- Wall Switch

- Push Button Switch

- Toggle Switch

- Membrane Switch

- DIP Switch

- Rocker Switch

- Reed Switch

- Time Switch

- Sensor Switch

- Slide Switch

- Flow Switch

- Tact Switch

- Automatic Transfer Switch

- Micro Switch

- Limit Switch

- Rotary Switch

- Pressure Switch

- Remote Control Switch

- Combination Switch

- Other Switches

- Battery & Storage Battery & Charger

- Battery Materials

- Battery Holder

- Storage Battery

- Fuel Cell

- Storage Battery Charger

- Other Battery & Storage Battery & Charger

- Lithium Battery

- Battery Pack

- Battery Management System

- Socket & Outlet

- Floor Socket & Table Socket

- Wall Socket

- USB Socket

- Face Plate

- Telephone Socket

- TV Socket

- PDU

- Extension Socket

- Audio & Video Socket

- Other Sockets & Outlets & Accessories

- Power Strips

- Power Transmission & Transformer

- Transformer

- Isolation Switch

- Instrument Transformer

- Insulator

- Transmission Tower

- Other Power Transmission & Transformer

- Optical Fiber & Cable & Wire

- Cable Conduit

- Cable Tray

- Cable Assembly

- Power Cable

- Power Cord & Extension Cord

- PV Cable

- Optical Fiber

- Enameled Wire

- Cable Tools

- Wire Harness

- Audio & Video Cable

- Other Wire & Cable

- Electric Wire & Cable

- Insulated Wire

-

Toys

- Intellectual & Educational Toys

- Activity Cube

- Art and Craft Toys

- Bath Toys

- Children's Book

- Construction and Engineering Toys

- DIY Toys

- Doll House

- Dress Up & Pretend Play

- Learning Machine

- Letters and Language Toys

- Play House

- Play Mat

- Science Toys

- Sorting & Stacking Toys

- Teaching Toys

- Track Toys

- Other Intellectual & Educational Toys

- Puzzle

- Other Educational Toys

- Other Puzzles

- Building Block Sets

- 3D Puzzles

- Learning Machines

- Kids Bike

- Magical Toys

- Model & Miniature Toys

- Musical Toys

- Novelty Toys

- Plastic Toys

- Plush & Stuffed Toy

- Remote Control Toys

- Sports & Fitness

- Sword & Gun Toys

- Toy Accessories

- Toy Stocks

- Vehicle Toys

- Wooden Toys

- Other Toys

- Pet Toys

- Cat Toys

- Dog Toys

- Other Pet Toys

- Adult Toys

- Artificial Toys

- Baby Toys

- Ball

- Cartoon Character

- Ceramic Toys

- Doll & Puppet

- Electrical Toys

- Fidget Toys

- Finger Toys

- Handheld Games

- Rubik's Cube

- Spinning Top

- Squishy Toys

- Other Fidget Toys

- Folk Toys

- Inflatable Toys

- Inflatable Ball

- Inflatable Boat

- Inflatable Bouncer

- Inflatable Cartoon

- Inflatable Pool

- Inflatable Slide

- Other Inflatable Toys

-

Light Industry & Daily Use

- Pet Supplies

- Pet House

- Pet Carriers & Travel Products

- Pet Beds & Accessories

- Pet Training & Behavior Products

- Pet Caskets & Urns

- Food Bowl & Water Bowl

- Pet Clothing & Accessories

- Pet Leash & Lead

- Pet Food

- Pet Collar

- Pet Harness

- Pet Training Supplies

- Aquariums & Accessories

- Other Pet Supplies

- Pet Cleaning & Grooming Products

- Barware

- Ice Bucket

- Bar Tool

- Bar Accessories

- Wine Cup

- Hip Flask

- Bar Set

- Drinking Straw

- Kitchen Implements

- Chopping Board

- Scoop & Ladle

- Kitchen Tongs

- Kitchenware Set

- Kitchen Knives

- Kitchen Mill

- Egg Whisk

- Cocktail Shaker

- Colanders & Strainers

- Cruet & Spice Jar & Bottle

- Kitchen Racks

- Strainer

- Knife Sharpener

- Cheese Tools

- Meat & Poultry Tools

- Salad Tools

- Sushi Tools

- Peeler

- Pasta Tools

- Other Kitchen Implements

- Bakeware

- Kitchen Scale

- Grater

- Ice Cube Tray

- Cup & Mug

- Glass Cup & Mug

- Stainless Steel Cup & Mug

- Porcelain Cup & Mug

- Cup & Saucer Set

- Silicone Cup & Mug

- Plastic Cup & Mug

- Ceramic Cup & Mug

- Bamboo Fiber Cup

- Other Cups & Mugs

- Disposable Cup & Mug

- Household Receptacle

- Vacuum Flask & Thermos

- Storage Utensils

- Storage & Organization

- Pot & Kettle

- Sprayer Bottle

- Sprayer Head

- Bottle

- Tissue Box

- Other Household Receptacle

- Makeup

- Lipstick

- Lip Gloss

- Eye Shadow

- Eyeliner

- Eyebrow Pencil

- Foundation

- Makeup Remover

- Mascara

- Concealer

- Blush

- Makeup Set

- Lip Liner

- Lip Balm

- Body Glitter

- Makeup Base

- Other Makeup Products

- Nail Beauty Products

- Nail Polish

- Gel Polish

- Nail Lamp

- Nail Acrylic Powder

- Nail Polish Remover

- Manicure & Pedicure Set

- Nail Printer

- Nail Dryer

- Nail Clippers

- Nail Glue

- Nail Decoration

- Nail Brush

- Nail File

- Other Nail Beauty Products

- Beauty & Personal Care Products

- Beard Care

- Essential Oil

- Perfume

- Hot Cold Therapy Bag

- Hand Warmer

- Warm Patch

- Hot Water Bottle

- Hair Removal

- Body Art Tools

- Bathroom Sets

- Breast Care

- Sleep Mask

- Other Personal Care Appliances

- Deodorant & Antiperspirant

- Shaving & Hair Removal

- Skin Cleaning Tools

- Personal Grooming

- Eyewear

- Glasses

- 3D Glasses

- Reading Glasses

- Glasses Cloth

- Glasses Case & Pouch

- Glasses Frames

- Glasses Parts

- Glasses Lens

- Contact Lens & Care Products

- Other Eyewear

- Skin Care

- Facial Mask

- Blemish Balm Cream

- Lip Mask

- Sunscreen

- Skin Care Set

- Hand Cream

- Facial Cleanser

- Skin Care Essence

- Body Scrub

- Neck Mask

- Face Lotion & Gel

- Tanning Lotion

- Body Cream & Lotion

- Skin Toner

- Eye Mask

- Eye Cream

- Other Skin Care

- Makeup Tools

- Makeup Brushes

- False Eyelashes

- Cotton Buds

- Nose Hair trimmer

- Powder Puff

- Makeup Tool Kits

- Makeup Scissors

- Makeup Mirror

- Cotton Pads

- Eyelash Glue

- Eyebrow Tweezers

- Eyebrow Trimmer

- Makeup Sponge

- Eyeshadow Brush

- Other Makeup Tools

- Eyelash Curler

- Household Chemicals

- Household Disinfectant

- Toilet Cleaner

- Air Freshener

- Laundry Ball

- Laundry Soap

- Other Household Chemicals

- Hand Washing Liquid

- Laundry Detergent

- Dish Detergent

- Disposable Products

- Disposable Shoe Covers

- Disposable Towel

- Disposable Cap

- Disposable Sanitary Products

- Disposable Gloves

- Disposable Apron

- Disposable Oversleeves

- Other Disposable Products

- Disposable Tableware

- Oral Care

- Toothpick

- Toothpaste

- Toothbrush

- Mouth Wash

- Tooth Powder

- Other Oral Care

- Dental Floss

- Bath Supplies

- Soap

- Shower Gel

- Sauna Hat

- Sauna Bucket & Ladle

- Shower Cap

- Bath Sponge & Brush & Scrubber

- Bath Pillow

- Bath Gloves

- Bath Salt

- Other Bath Supplies

- Paper for Household & Sanitation

- Sanitary Paper

- Sanitary Napkins

- Wet Wipes

- Paper Towel

- Adult Wipes

- Facial Tissue & Serviette

- Toilet Paper

- Other Paper for Household & Sanitation

- Adult Diapers

- Underpad

- Hair Tools & Accessories

- Hair Comb & Brush

- Hair Extension Tools

- Hair Roller

- Hair Scissors

- Hair Foil

- Cap Highlights

- Hairdressing Cape & Gown

- Other Hair Tools & Accessories

- Baby Goods

- Baby Diapers

- Baby Wipes

- Strollers & Walkers & Carriers

- Nasal Aspirator

- Bathing & Skin Care

- Baby Safety Lock

- Potty

- Baby Changing Station

- Baby Car Seats

- Baby Bib

- Feeding Supplies

- Other Baby Products

- Ladders & Scaffoldings

- Ladders

- Horticulture & Gardening Products

- Flower Pot & Planter

- Shovel & Spade

- Garden Hose Reel

- Garden netting

- Lawn Mower

- Garden Blower & Vacuum

- Shovel & Spade

- Earth Auger

- Electric Fence Energizer

- Weed Mat

- Brush Cutter

- Flower Stand

- Garden Ornaments

- Chainsaw

- Hedge Trimmer

- Watering Can

- Gardening Tool Parts

- Hoe

- Garden Fencing

- Garden Sprinkler

- Garden Hose

- Pickaxe

- Other Horticulture & Gardening Products

- Rake

- Sprayers

- Shears

- Garden Water Connectors

- Household Plastic Products

- Plastic Rope & Net

- Plastic Tube & Pipe & Hose

- Household Plastic Containers

- Plastic Fresh Bag

- Shrink Wrap

- Household Cleaning

- Household Gloves

- Laundry Products

- Awning & Umbrella & Raincoat

- Awning

- Raincoat

- Umbrella

- Match & Lighter & Smoking Set

- Match

- Hookah

- Cigarette Case & Box

- Cigar Humidor & Case

- Smoking Pipe

- Ashtray

- Smoking Accessories

- Other Smoking Sets

- Lighter

- Drinkware

- Stovetop Espresso & Moka Pots

- Water Bottle

- Ceramics & Porcelain & Enamel

- Darning & Sewing Utensil

- Exhibition and Advertising Equipment

- Billboard

- Advertising Letter

- Flagpole

- Roll up Display

- Banner Stand

- Display Stand

- Truss

- Other Exhibition and Advertising Equipment

- Garden Sprayer

- Tableware

- Lunch Box

- Fork

- Dinner Knife

- Bowls

- Dinner Sets

- Cutlery Sets

- Chopsticks

- Plates

- Dishes & Plates

- Spoon

- Tray

- Tureen

- Other Tablewares

- Glassware

- Hair Care Products

- Hair Mask

- Hair Conditioner

- Hair Dye

- Perm Solution

- Hair Styling Products

- Shampoo

- Hair Treatment Products

- Other Hair Care Products

- Hotel Amenities

- Household Rubber Products

- Inflatable Advertising

- Kitchen Textile

- Cloth Napkins

- Kitchen Rugs

- Kitchen Gloves

- Other Kitchen & Table Textile

- Cleaning Ball, Sponge & Cloth

- Table Runner

- Apron

- Labels

- Adhesive Label

- Other Label

- Ladder

- Laundry Basket

- Lens Cleaner

- Paper Material

- Restaurant Supplies

- Chafing Dish

- Other Restaurant Supplies

- Tape & Adhesive

- Other Daily Use

- Sanitary Utensil

- Mop

- Broom & Dustpan

- Duster

- Sticky Roller

- Garbage Bag

- Lint Remover

- Razor Scraper

- Cleaning Ball & Sponge & Cloth

- Shoe Covers & Shoe Covers Dispenser

- Other Sanitary Utensils

- Cleaning Brush

- Squeegees

- Buckets

- Dustbin

- Cleaning Cloths

- Kitchen & Bathroom Cleaning

- Drain Cleaners

- Multi-purpose Cleaners

- Toilet Cleaners

- Scale Removers

- Home Storage & Organization

- Storage Holders & Racks

- Storage Boxes & Bins

- Pest Control

- Household Sundries

- Clock & Watch

- LED Watch

- Silicone Watch

- Nurse Watch

- Pocket Watch

- Steel Watch

- Grandfather Clock

- Wooden Watch

- Alarm Clock

- Leather Strap Watch

- Ceramic Watch

- Sports Watch

- Clock & Watch Accessories

- Desk & Table Clock

- Other Clocks & Watches

- Wall Clock

- Bedding

- Quilt

- Quilt Cover

- Bed Sheets

- Mattress Cover

- Bedding Set

- Bed Pillow

- Bedspread

- Cushion Cover

- Backrest Pillow & Cushion

- Blanket

- Matting

- Pillow Case

- Other Bedding Textile

- Mosquito Net

- Rack & Shelf & Holder & Hanger

- Drying Rack

- Bathtub Rack

- Other Racks & Shelf

- Ironing Board

- Toothbrush Holder

- Hanger

- Cookware

- Cookware Parts

- Cookware Set

- Dutch Ovens

- Griddles

- Stock Pots

- Steamers

- Saucepans

- Other Cookware

- Pressure Cookers

- Coffee & Tea Set

- Other Drinkware

- Kettles

- Soup & Stock Pots

- Pans

- Woks

-

Auto & Motorcycle Parts & Accessories

- Car Electrical Appliances

- Automotive Vacuum Cleaner

- Car Refrigerator

- Car Rice Cooker

- Car Fan

- Car Air Purifier

- Other Car Electrical Appliances

- Motorcycle Parts & Accessories

- Motorcycle Batteries

- Motorcycle Body Parts

- Motorcycle Electronic

- Motorcycle Engines

- Motorcycle Helmets

- Motorcycle Trunk

- Motorcycle Shock Absorbers

- Motorcycle Rotation And Transmission Components

- Other Motorcycle Parts & Accessories

- Tire & Accessories

- Truck Tire

- Car Tire

- Motorcycle Tire

- Wheelbarrow Wheel

- Agricultural Tire

- Electric Bike Tire

- Industrial Tire

- OTR Tire

- Off Road Tire

- Tire Chain

- Tire Valve

- Truck & Bus Tire

- Other Tires

- Wagon Tire

- Bicycle Tire

- Wheel Parts

- Auto Engine

- Car Maintenance

- Antifreeze & Coolant

- Car Polisher

- Car Wax

- Fuel Additives

- High Pressure Car Washer

- Ice Scraper

- Paint Spray Gun

- Other Car Maintenance

- Car Cleaning Chemical

- Auto Parts & Accessories

- Auto Electronics

- Suspension System

- Brake System

- Vehicle Repair Equipment & Tools

- Parking Equipment

- Auto Painting Equipment

- Automotive Test Equipment

- Booster Cables

- Car Bench

- Car Lift

- Jump Starter

- Repair Tools

- Tyre Changer

- Warning Triangle

- Wheel Alignment

- Wheel Balancer

- Other Auto Repair Equipment & Tools

- Car Jacks

- Diagnostic Tools

- Dock Levlers

- Emergency Tools

- Grease Guns

- Ramps

- Tie Downs

- Tire Compressors

- Tire Gauges

- Tire Inflators

- Tire Pressure Monitoring System (TPMS)

- Tire Repair Tools

- Transmission Jacks

- Car Lock & Motorcycle Lock & Bicycle Lock

- Auto Electrical System

- Auto Meter

- Auto Relay

- Car Alternator

- Car Battery

- Car Speakers & Horn

- Car Switch

- Fuse Holder & Car Fuses

- Other Auto Electrical System

- Auto Engine Structure

- Air Intake

- Cooling System

- Engine Mount

- Exhaust System

- Fuel System

- Ignition System

- Lubrication System

- Muffler

- Starter Motor

- Turbocharger

- Valve System

- Other Auto Engine Structure

- Auto Parts

- Brake

- Clock Spring

- Clutch

- Drive Shaft

- Shock Absorber

- Universal Joint

- Wheel Hub & Rim & Spoke

- Other Auto Parts

- Auto Bearing

- Auto Compressor

- Auto Filter

- Auto Steering Systems

- Axles

- Auto Sensor

- Throttle Position Sensor

- Other Auto Sensors

- ABS Sensor

- Auto Winch

- Car Accessories

- Car Bumper

- Car Door

- Car Fender

- Car Glass & Window

- Car Grille

- Car Ramp

- Car Seat

- Shift Knob

- Side Step

- Spoiler

- Tail Lift

- Wiper Blade & Arm & Motor

- Other Car Accessories

- Car Air Conditioning System

- Blower Motor

- Car Condenser

- Car Evaporator

- Receiver Drier

- Other Car Air Conditioning System

- Car Decoration

- Car Cover

- Car Film

- Car Holder

- Car Mat

- Car Organizer

- Car Perfume & Air Freshener

- Car Roof Box & Rack

- Car Seat Cover & Cushion

- Car Sticker

- Car Sunshade

- License Plate Frame

- Steering Wheel Covers

- Window Visor

- Other Car Decoration

- Car Electronics

- Car Audio

- Car Charger

- Car Communications

- Car Video

- Other Car Electronics

- Car Light & Auto Mirror

- Brake Light

- Car Interior Light

- Fog Light

- Headlight

- LED Light Bar

- License Plate Light

- Rear Light

- Rear View Mirror

- Reverse Light

- Turn Light

- Other Car Lights & Auto Mirrors

- Car Safety

- Car Alarm

- Car Black Box

- Car DVR

- Car Radar

- Car Rearview Camera

- Car Rearview Monitor

- Other Car Safety

- Crank Mechanism

- Auto Cylinder

- Connecting Rod

- Crankshaft

- Cylinder Head

- Cylinder Head Cover

- Cylinder Head Gasket

- Cylinder Liner

- Flywheel

- Oil Pan

- Piston

- Piston Pin

- Piston Ring

- Other Crank Mechanisms

- Ratchet Straps & Buckle

- Ratchet Buckle

- Ratchet Straps

- Other Parts & Accessories

- New Energy Vehicle Parts & Accessories

- Charging Stations

- Charging Cable

- DC-DC Converter

- EV Battery

- EV Connector

- EV Inverter

- EV Motor

- Electric Pedal

- Motor Controller

- On-board Charger

- Other NEV Parts & Accessories

-

Construction & Decoration

- Kitchen Appliance

- Bathroom & Kitchen

- Bathroom Basin & Sink

- Sink Accessories

- Toilet Plungers

- Shower Curtains

- Kitchen Sink

- Faucets & Mixers & Taps

- Shower Room & Shower Enclosure

- Computerized Shower Room

- Simple Shower Room

- Shower Base

- Shower Doors

- Shower Screen

- Steam Shower Room

- Other Shower Room, Shower Enclosure & Accessories

- Brick & Tile & Accessories

- Roof Tile

- Construction Equipment & Tools

- Scaffolding Net

- Caulking Gun

- Glass Cutter

- Putty Knife

- Formwork

- Scaffolding

- Suspended Platform

- Other Construction Equipment & Tools

- Plaster Trowel

- Bricklaying Trowel

- Decoration Materials

- Moulding

- Aluminum Composite Panel

- WPC Board

- Wallpaper

- Wall Tile Sticker

- Cement Board

- Corner Bead

- Decorative Film

- Decorative Paper

- Door Skin

- Honeycomb Core

- Honeycomb Panel

- Sandwich Panel

- Skirting

- Other Decoration Materials

- Wall Panels

- Building Glass

- Tempered Glass

- Clear Glass

- Frosted Glass

- Insulated Glass

- Laminated Glass

- Patterned Glass

- Special Glass

- Stained Glass

- Tinted Glass

- Wired Glass

- Other Building Glass

- Mirror

- Bathroom Mirror

- Decorative Mirrors

- Full-Length Mirror

- Other Mirrors

- Wire Mesh

- Stainless Steel Wire Mesh

- Expanded Metal Mesh

- Cattle Panel Fencing

- Crimped Wire Mesh

- Filter Screen

- Gabion

- Metal Wire

- Perforated Metal

- Plastic Coated Wire Mesh

- Square Mesh

- Other Wire Meshes

- hexagonal wire netting

- Chain Link Fence

- Barbed Wire

- Welded Wire Mesh

- Galvanized Wire

- Iron Wire Mesh

- Shower Head & Shower Set

- Shower Faucet

- Shower Head

- Shower Hose

- Shower Panel

- Other Shower Heads & Shower Sets

- Shower Set

- Lock

- Door Lock

- Smart Locks

- Padlock

- Furniture Lock

- Lock Key & Accessories

- Industrial Lock

- Lock Cylinders

- Window Lock

- Card Lock

- Combination Lock

- Locksmith Tools

- Other Locks

- Fireplaces & Stoves

- Stoves

- Door

- Plastic Door

- Metal Door

- Security Door

- Wooden & Timber Door

- Glass Door

- Other Doors

- Automatic Door

- Composite Door

- Garage Door

- Toilet & Accessories

- Bidet

- Squat Pan

- Toilet

- Toilet Flush Valve

- Toilet Tank

- Toilet Tank Parts

- Urinal

- Other Toilet & Accessories

- Toilet Seat

- Timber & Plywood

- Bamboo

- Blockboard

- Fiberboard

- Finger Jointed Boards

- Log and Veneer

- Melamine Board

- Particle Board

- Solid Wood Board

- Other Artificial Wood

- Plywood

- Ceiling

- PVC Ceiling

- Calcium Silicate Ceiling

- Ceiling Grid

- Fiberglass Ceiling

- Metal Ceiling

- Mineral Wool Ceiling

- Plasterboard Ceiling

- Polystyrene Ceiling

- Other Ceilings

- Plasterboard

- Waterproof Building Materials

- Waterproofing Membrane

- Floors & Flooring

- Floor Tile

- Plastic Floor

- Wood Plastic Composite Flooring

- Anti-static Flooring

- Bamboo Floor

- Engineered Wood Flooring

- Flooring Accessories

- Laminate Flooring

- Rubber Floor

- Wood & Hardwood Floor

- Other Floors

- Curtain Wall & Accessories

- Curtain Wall

- Curtain Wall Profile

- Glass Spider

- Other Curtain Wall Accessories

- Bath Mat

- Blinds & Shades & Shutters

- Bridge & Bridge Structure

- Bridge

- Bridge Bearing

- Other Bridge Structures

- Building Heater

- Fireplace & Stove & Parts

- Heating Radiator

- Other Building Heater

- Building Sealing

- Window

- Composite Window

- Metal Window

- Plastic Window

- Wooden Window

- Other Windows

- Building Steel & Structure

- Steel Grating

- Other Building Steel & Structures

- Cement & Precast Component

- Concrete & Mortar & Admixtures

- Construction Accessories

- Construction Materials Stocks

- Construction Pipe & Tube

- Aluminum Tube & Pipe

- Composite Pipe & Tube

- Copper Pipe & Tube

- Iron Pipe & Tube

- Other Pipes & Tubes

- Doorbell

- Faucet & Tap & Mixer

- Basin Faucet

- Bidet Faucet

- Faucet Parts

- Kitchen Mixer & Faucet

- Lab Faucet

- Tub Faucet

- Other Faucets & Taps & Mixers

- Bathroom Fittings & Accessories

- Soap Dispenser

- Towel Rack

- Bathroom Hardware Sets

- Bathroom Rack

- Coat Hooks

- Grab Bar

- Toilet Brush Holder

- Towel Bar

- Towel Ring

- Tumbler Holder

- Other Bathroom Fittings & Accessories

- Drain

- Paper Holder

- Soap Dish

- Fence

- Airport Fence

- Balcony Fence

- Bridge Fence

- Farm Fence

- Highway Guard Rail

- Railway Fence

- Security Fence

- Soundproof Fence

- Stadium Fence

- Stair Fence

- Other Fences

- Fire Retardant & Fireproof Material

- Geosynthetics Products

- Geocell

- Geocomposite

- Geogrid

- Geomembrane

- Geonet

- Geotextile

- Other Geosynthetics Products

- HVAC System & Parts

- Partition

- Toilet Partitions

- Other Partitions

- Plumbing Hardware

- Prefabricated Building

- Sand & Lime & Plaster

- Sauna Room

- Dry Sauna Room

- Sauna Heater

- Steam Generator

- Wet Steam Room

- Other Sauna Room & Accessories

- Sink & Basin

- Lab Sink

- Other Sink & Basin

- Slate & Marble & Granite & Stone

- Artificial Stone

- Basalt

- Countertop & Vanity Top

- Granite

- Limestone

- Mantel

- Marble

- Paving Stone

- Pillar

- Quartz Stone

- Sandstone & Cobble & Pebble

- Slate

- Tombstone & Monument

- Other Stones

- Heat Insulation

- EPS Foam Board

- XPS Foam Board

- Thermal Insulation Coating

- Glass Wool

- Heat Insulation Film

- Silicate Insulation

- Aerogel Felt

- Rock Wool

- Other Heat Insulation Material

- Sound Absorption Materials

- Special Building Materials

- Stairs & Stair Parts

- Stair Parts

- Stairs

- Steel Structure

- Steel Frame

- Steel Staircase

- Steel Structure Platform

- Steel Structure Bridge

- Steel Roof

- Steel Walkway & Floor

- Steel Column

- Other Steel Structure

- Other Building & Decoration Materials

- Shaped Building Material

- Copper Profile

- Fiberglass Profile

- Other Shaped Building Material

- Aluminum Profile

- Plastic Profile

- Floor Heating Systems & Parts

- Garden Supplies

- Bathtub

- Pipe Fittings

- Union

- Other Pipe Fittings

- Elbow

- Tee

- Bushing

- Headstock

- Coupling

- Cross

- Expansion Joint

- Nipple

- Reducer

- Sight Glass

- Home Decoration

-

Lights & Lighting

- LED Interior Lighting

- LED Bulb Light

- LED Panel Light

- LED Table Lamp & Book Light

- LED Wall Light

- LED Pendant Light

- LED Ceiling Light

- LED High Bay Light

- LED Grille Light

- LED Track Light

- LED Spotlight

- LED Down Light

- LED Linear Light

- LED Cup

- Dimmable Bulb

- Candle Light

- Other LED Interior Lighting

- LED Tube

- LED Outdoor Lighting

- LED Floodlight

- LED Lawn Light

- LED Street Light

- LED Point Light

- LED High Mast Light

- LED Outdoor Wall Light

- LED Tunnel Light

- LED Garden Light

- LED Wall Washer

- Other LED Outdoor Lighting

- LED Underground Light

- Professional Lighting

- LED Mirror Lamp

- Flashlights & Torches

- LED Emergency Light

- Working Light

- Solar lighting

- Solar Flood Lights

- Solar Street Lights

- Solar Light

- Interior Lighting

- Ceiling Light

- Wall Light

- Pendant Light

- Floor Lamp

- Other Indoor Lighting

- Table Lamp & Reading Light

- Downlights

- LED Lighting Decoration

- Other LED Lighting Decoration

- LED Strip Light

- LED String Light

- Bulb & Lamp

- LED Bulbs

- Incandescent Bulbs

- Halogen Bulbs

- Mercury Lamps

- LED Tubes

- Energy Saving & Fluorescent

- Metal Halide Lamps

- High Pressure Sodium Lamps

- Xenon Lamps

- Neon Bulbs & Tubes

- Incandescent Light

- Mercury Light

- Infrared Lamp

- Halogen Light

- Sodium Lamp

- Neon Bulb & Tube

- Fluorescent Light

- Ultraviolet Lamp

- Other Light Bulb & Tube

- Outdoor Lighting

- Garden Light

- Lawn Light

- Floodlight

- Underwater Light

- Other Outdoor Lighting

- Camping Light

- Spotlight

- Street Light

- Lighting Fixtures

- Lamp Base & Light Socket

- LED Retrofit Kit

- LED Aluminum Profile

- LED Heatsink

- Light Pole

- Lamp Shade

- Dimmer

- Ballast

- Light Bracket

- Other Lighting Fixtures

- LED Encapsulation Series

- LED Dot Matrix

- LED Module

- COB LED

- SMD LED

- Lamp LED

- Flip Chip LED

- High Power LED

- Super Flux LED

- Other LED Encapsulation Series

- LED Display

- Semi-outdoor LED Display

- Indoor LED Display

- Outdoor LED Display

- Portable Lighting

- Lighting Decoration

- Rope Light

- Tiffany Lamp

- Fiber Optic Light

- Lantern

- Metal Light

- Neon Light

- Motif Light

- Chandelier

- Other Decorative Lights

- Light Box

- Sensor Light

- Compact Bulb & Lamp

- U-Tube Compact Bulb & Lamp

- Spiral Compact Bulb & Lamp

- Special Tube Compact Bulb & Lamp

- Straight Tube Compact Bulb & Lamp

- Emergency Light & Indicator Light

- Aviation Obstruction Light

- Warning Light

- Emergency Light

- Indicator Light

- Other Emergency & Indicator Lights

- Light Stocks

- Stage Lighting

- LED Floor

- Laser Light

- Wall Washer Light

- Effect Light

- Moving Head Light

- Other Stage Lights

- Stage Equipment

- Bubble Machine

- Snow Machine

- Smoke Machine

- Other Stage Equipment

- LED Professional Lighting

- LED Fishing Light

- LED Cabinet Light

- LED Light Box

- LED Explosion-proof Light

- LED Work Light

- LED Traffic Light

- LED PAR Light

- LED Tri-proof Light

- LED Grow Light

- LED Fresh Light

- LED Flashlight

- LED Underwater Light

- LED Aquarium Light

- LED Headlamp

- LED Light for Animal Husbandry

- Other LED Professional Lighting

- Other Lights & Lighting

-

Furniture

- Commercial Furniture

- Office Partitions

- Salon Furniture

- Barber Chairs

- Other Hospital Furniture

- Other Commercial Furniture

- Bar Furniture

- School Chairs

- School Sets

- Bar Chairs

- Hospital Furniture

- Laboratory Furniture

- Super Clean Bench

- Lab Accessories

- Lab Cabinet

- Lab Stool & Chair

- Lab Bench

- Fume Hood

- Other Lab Furniture

- School Furniture

- Student Desk

- Student Chair

- Lectern

- Dormitory Bed

- School Furniture Sets

- Other School Furniture

- Furniture Parts & Accessories

- Office Chair Tripod

- Furniture Legs

- Edge Banding

- Chair Armrest

- Cabinet Doors

- Chair Mechanism

- Furniture Frame

- Patio Umbrella Base

- Other Furniture Parts & Accessories

- Outdoor Furniture

- Patio Umbrellas & Bases

- Canopy & Gazebo & Pergola

- Garden Sets

- Outdoor Tables

- Sun Loungers

- Garden Sofas

- Other Outdoor Furniture

- Patio Benches

- Garden Swing

- Garden Furniture Sets

- Garden Chair

- Beach Chairs

- Bathroom Furniture

- Bathroom Cabinets

- Other Bathroom Furniture

- Hallway Furniture

- Shoe Rack

- Shoe Cabinet & Shoe Rack

- Shoes Changing Stool

- Umbrella Stand

- Console Table

- Other Hallway Furniture

- Bedroom Furniture

- Wardrobe

- Bedroom Bed

- Dresser

- Mattress

- Nightstands

- Bed Bench

- Drawer Chest

- Dresser Stool

- Bedroom Furniture Sets

- Other Bedroom Furniture

- Coat Rack

- Office Furniture

- Filing Cabinets

- Other Office Furniture

- Office Chair

- Office Sofa

- Office Desk

- Gaming Chair

- Gaming Desk

- Computer Desk

- Executive Table

- Conference Table

- Training Desk

- Training Chair

- Home Office Furniture

- Office Bookcase

- Magazine & Newspaper Rack

- Reception Desk

- Dining Room Furniture

- Workbench

- Dining Chairs

- Dining Table

- Sideboard

- Dining Room Furniture Sets

- Other Dining Room Furniture

- Living Room Furniture

- Living Room Sofa

- Wall Shelf

- Chaise Lounge

- Sofa Bed

- Ottoman

- Stool

- Living Room Chairs

- Coffee Table

- Side Table

- TV Stand

- CD Rack

- Living Room Cabinets

- Living Room Furniture Sets

- Other Living Room Furniture

- Kitchen Furniture

- Kitchen Cart

- Kitchen Cabinets

- Kitchen Island

- Step Stool

- Other Kitchen Furniture

- Parcel Box

- Restaurant Furniture

- Restaurant Chairs

- Restaurant Table

- Restaurant Furniture Sets

- Other Restaurant Furniture

- Library Furniture

- Library Bookshelf

- Reading Table

- Other Library Furniture

- Store & Supermarket Furniture

- Cash Counter

- Promotion Table

- Showcase

- Supermarket Shelf

- Locker

- Shopping Basket & Cart

- Other Store & Supermarket Furniture

- Public Furniture

- Auditorium Chairs

- Bleachers

- Waiting Bench & Chair

- Bus Shelter & Taxi Stop

- Check-in Counter

- Other Public Furniture

- Other

- Other Furniture

- Other Furniture Sets

- Other Tables & Desks

- Other Stools

- Other Sofas

- Other Chairs

- Other Cabinets

- Other Beds

- Children & Baby Furniture

- Baby Rocking Chair

- Baby Crib

- Kids Dining Chair

- Kids Furniture Sets

- Kids Cabinet

- Kids Sofa

- Kids Wardrobe

- Kids Chair

- Kids Table

- Baby Playpen

- Other Children & Baby Furniture

- Hotel Furniture

- Hotel Chair

- Hotel Bed

- Luggage Rack

- Hotel Bedroom Furniture Sets

- Luggage Cart

- Hotel Lobby Furniture

- Other Hotel Furniture

- Cleaning Carts

-

Instruments & Meters

- Weighing & Measuring Apparatus

- Electronic Scale

- Weight Indicator

- Truck Scale

- Crane Scale

- Checking Fixture

- Measuring Device

- Gauge

- Platform Scale

- Balance

- Other Weighing & Measuring Apparatus

- Jewelry Scales

- Check Weigher

- Body Scale

- Weighing Scales

- Geographic Surveying Instrument

- Test Instruments

- Optical Instruments

- Other Optics Instruments

- Physical Measuring Instruments

- PH Meters

- Spectrometers

- Other Analysis Instruments

- Measuring & Analysing Instrument Stock

- Other Test Instruments

- Battery Tester

- Environmental Test Chamber

- Melting Point Apparatus

- Test Machine

- Sun Simulator

- Cable Tester

- Component Tester

- Other Instruments & Meters

- 3D Scanner

- Meter for Electricity

- Current Meter

- Voltage Meter

- Resistance Meter

- Energy Meter & Power Meter

- Multimeter

- Other Meters for Electricity

- Electronic Instrument

- Frequency Meter

- Clamp Meter

- Oscilloscope

- Data Logger

- Calibrator

- Signal Generator

- Other Electronic Instruments

- Analysis Instrument

- Laser Particle Size Analyzer

- Concentration Meter

- Gas Analyzer

- Chromatography & Spectroscopy Instrument

- Food Safety Tester

- Moisture Meter

- Sample Processor

- Liquid Analyzer

- Audio Analyzer

- Element Analyzer

- Light Meter

- Optical Lens & Instrument

- Rangefinder

- Magnifier

- Optical Mirror

- Optical Lens

- Laser Level

- Theodolite

- Prism

- Optical Filter

- Telescope & Binoculars

- Microscope

- Night Vision

- Video Measuring System

- Refractometer

- Other Optical Lens & Instruments

- Lab Utensil and Disposable

- Flasks

- Beakers

- Pipettes

- Buret

- Cover Glass

- Centrifuge Tube

- Funnel

- Petri Dish

- Deep Well Plate

- Lab Clamp

- Laboratory Cylinder

- Test Tube Rack

- Test Paper

- Pipette

- Sample Container

- Slide Glass

- Syringe Filter

- Other Lab Utensils and Disposables

- Meter for Liquid & Gas

- Flow Meter

- Gas Meter

- Water Meter

- Thermometer & Hygrometer

- Pressure Gauge

- Liquid Level Meter

- Other Meters for Liquid & Gas

- Laboratory Instruments

- Laboratory Refrigeration Equipments

- Laboratory Centrifuge

- Lab Drying Equipment

- Laboratory Heating Equipments

- Laboratory Filtration Equipment

- Laboratory Thermostat

- Laboratory Refrigeration Equipment

- Lab Balance

- Other Lab Instruments

- Detector

- X-Ray Detector

- Walkthrough Metal Detector

- Explosive Detector

- Underground Metal Detector

- Groundwater Detector

- Drug Detector

- Needle Detector

- Life Detector

- Metal Detector for Food

- Handheld Metal Detector

- Test Probe

- Other Detectors

- Physical Measuring Meter

- BET Surface Area Analyzer

- Dynamometer

- Speed Measuring Meter

- Hardness Tester

- Viscometer & Density Meter

- Other Physical Measuring Meters

- Instrument Box

- Automated Inspection Equipment

- Timer & Counter

-

Industrial Equipment & Components

- Other Equipment & Components

- Cutter & Tongs

- Vise

- Saw Blade

- Boring Tool

- Broach

- Chuck

- Dividing Head

- Hob Cutter

- Milling Cutter

- Reamer

- Rotary Table

- Turning Tool

- Other Cutters & Tongs

- Valve

- Reducing Valve

- Solenoid Valve

- Butterfly Valve

- Diaphragm Valve

- Angle Valve

- Globe Valve

- Inlet Valve

- Control Valve

- Exhaust Valve

- Ball Valve

- Sampling Valve

- Steam Trap

- Plug Valve

- Blind Valve

- Gate Valve

- Needle Valve

- Check Valve

- Safety Valve

- Mini Pressure Valve

- Other Valves & Parts

- Guide Rail

- Testing Instrument & Equipment

- Universal Hardware Parts

- Welding & Soldering Supplies

- Welding Flux

- Welding Wire

- Other Welding & Soldering Supplies

- Welding Helmet

- Welding Torch

- Electrode Holder

- Welding Rod

- Refrigeration Equipment

- Industrial Chiller

- Industrial Air Conditioner

- Condenser

- Industrial Cooling System

- Ice Machine

- Cold Room

- Refrigeration Machinery

- Quick Freezer

- Other Refrigeration Equipment & Parts

- Cleaning Equipment

- Floor Polisher

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Corner Cleaning Machine

- Abrator

- Sandblaster

- Cleaning Machine Parts

- Floor Sweeper

- Snow Blower

- Floor Scrubber

- Other Cleaning Machines

- Compressor

- Compressor Unit

- Centrifugal Compressor

- Compressor Parts

- Linear Compressor

- Reciprocating Compressor

- Rotary Compressor

- Screw Compressor

- Scroll Compressor

- Other Compressors

- Pump & Vacuum Equipment

- Pump Parts

- Gear Pump

- Diaphragm Pump

- Piston Pump

- Centrifugal Pump

- Screw Pump

- Jet Pump

- Peristaltic Pump

- Water Pump

- Pressure Pump

- Vane Pump

- Gasoline & Gas Pump

- Vacuum Pump

- Plunger Pump

- Self-Priming Pump

- Other Pump & Vacuum Equipment

- Power Transmission Parts

- Shaft Coupling

- Slewing Drive

- Speed Reducer

- Sprocket

- Transmission Chain

- Transmission Pulley

- Worm

- Other Power Transmission Parts

- Gear

- Gearbox

- Transmission Belt

- Welding Equipment

- Arc Welder

- Brazing Machine

- Butt Welder

- Friction Welder

- MIG Welder

- Plasma Welder

- Plastic Welder

- Press Welder

- Resistance Welder

- Seam Welder

- Soldering Iron Tip

- Soldering Machine

- Spot Welder

- Tube Welder

- Welding Auxiliary Equipment & Apparatus

- Welding Tips

- Other Welding Equipments

- Electric Soldering Iron

- Washing Equipment

- Dry Washer

- Industrial Laundry Dryer

- Industrial Spin Dryer

- Industrial Washer

- Ironing Machine

- Laundry Folding Machine

- Washing Auxiliary Equipment & Apparatus

- Washing Equipment Parts

- Other Washing Equipment

- Sealing & Gaskets

- Lead Seal

- Mechanical Seal

- Seal Packing

- Seal Ring

- Sealing Strip

- Other Seals

- Oil Seal

- Heater & Heat Exchanger

- Heat Exchanger

- Heat Exchanger Plate

- Liquid Cold Plate

- Thermal Module

- Vapor Chamber

- Other Heaters & Heat Exchangers

- Air Clean Equipment

- Air Clean Equipment Parts

- Air Shower

- Pass Box

- Other Air Clean Equipments

- Ball Screw

- Bearing

- Angular Contact Ball Bearing

- Bearing Accessories

- Cylindrical Roller Bearing

- Deep Groove Ball Bearing

- Four Point Contact Ball Bearing

- Linear Bearing

- Needle Bearing

- Pillow Block Bearing

- Plain Bearing

- Self-Aligning Ball Bearing

- Slewing Bearing

- Special Bearing

- Spherical Plain Bearing

- Spherical Roller Bearing

- Taper Roller Bearing

- Thrust Ball Bearing

- Thrust Needle Roller Bearing

- Thrust Self-aligning Roller Bearing

- Thrust Taper Roller Bearing

- Other Bearing

- Boiler & Furnace

- Boiler Parts

- Furnace

- Furnace Parts

- Conveyor & Parts

- Conveyor Belt

- Conveyor Chain

- Conveyor Frame

- Conveyor Idler

- Conveyor Roller

- Hopper

- Other Conveyors & Parts

- Conveyors

- Drying Machine

- Belt Drying Machine

- Compressed Air Dryer

- Drum Drying Machine

- Dry Cabinet

- Drying Oven

- Flash Drying Machine

- Fluid Bed Drying Machine

- Rotary Drying Machine

- Spray Drying Machine

- Vacuum Drying Machine

- Other Drying Machines

- Electrostatic Eliminator

- Engine & Part

- Engine

- Engine Parts

- Environment Protection Device

- Noise Reduction Device

- Oil Boom & Oil Absorbent

- Oxygen Generator

- Ozone Generator

- Sewage Treatment Equipment

- Waste Treatment Equipment

- Water Disinfection System

- Water Tank

- Other Environment Protection Device

- Filtration Equipment & Parts

- Air Filter

- Dust Collector

- Filter Bag & Cartridge

- Filter Cloth

- Filter Element

- Filter Membrane

- Filter Mesh

- Filter Paper

- Filter Plate

- Filter Press

- Industrial Water Filter

- Machine Oil Purifier

- Oil Filter

- Reverse Osmosis System

- Other Filtration Equipment & Parts

- Gas Generation Equipment & Parts

- Industrial 3D Printer

- Industrial Adhesive Products

- Industrial Glue

- Industrial Tape

- Other Industrial Adhesive Products

- Industrial Brake

- Industrial Customized Service

- Heat Treatment

- Machining Service

- Plastic Molding

- Powder Injection Molding

- Powder Metallurgy

- Sheet Metal Fabrication

- Welding Service

- Other Custom Fabrication Service

- 3D Printing Service

- Coating Service

- Industrial Humidifier & Dehumidifier & Parts

- Industrial Dehumidifier

- Industrial Dehumidifier Parts

- Industrial Humidifier

- Linear Actuator

- Machinery Stocks

- Mass Transfer and Separation Equipment

- Mass Transfer Equipment

- Mass Transfer Equipment Parts

- Separation Equipment Parts

- Pipe & Tube System

- Pneumatic Component

- Cylinder

- Pneumatic Actuator

- Pneumatic Filter

- Pneumatic Fittings

- Pneumatic Pipe

- Pneumatic Seal

- Pneumatic Valve

- Source Treatment Unit

- Other Pneumatic Components

- Power & Generating Sets

- Biomass Generator

- Diesel Generator

- Gas Generator

- Gasoline Generator

- Generator Parts & Accessories

- Hydro Generator

- Solar Generator

- Steam Turbine Generator

- Wind Generator

- Other Generators

- Ventilation Equipment

- Blowers

- Air Vent

- Ventilation Duct

- Other Ventilation Equipment & Parts

- Ventilation Fan

- Shaft

- Valve Parts

- Valve Actuator

- Valve Ball

- Valve Body

- Valve Cap

- Valve Needle

- Valve Seat

- Valve Stem

- Valve Strainer

-

Consumer Electronics

- Mobile Phone & Accessories

- Stylus

- Mobile Phone Charger

- Mobile Phone Battery

- Mobile Phone Earphone

- Mobile Phone Keypad

- Mobile Phone Flex Cables

- Mobile Phone Cable

- Mobile Phone Housing

- Mobile Phone LCD

- Mobile Phone Holder

- Mobile Phone

- Power Bank

- Selfie Stick

- Other Mobile Phone Accessories

- Office Electronics

- Photographic Apparatus

- Professional Photographic Equipment

- Film

- Film Camera

- Photographic Accessories

- Digital Camera

- Camera Battery

- Camera Charger

- Camera Lens

- Portable Audio Appliance

- CD & MD & Cassette Player

- Hi-Fi Player

- MP3 Player

- Portable Audio Recorder

- Other Portable Audio Appliances

- Radio & Cassette Recorders

- Screen Protector

- Hand Dryer

- Secondhand Consumer Electronics

- Shaver

- Steam Cleaner

- Telephone

- Refrigerator & Freezer & Parts

- Home Refrigerator & Freezer

- Commercial Refrigerator & Freezer

- Freezer & Refrigerator Parts

- Other Refrigerators & Freezers

- Temperature Measuring Apparatus

- Two Way Radio

- UGV

- Ultrasonic Cleaner

- Video

- MP4 Player

- Video Camera & Accessories

- Video Glasses

- Digital Photo Frame

- VCD & DVD Player

- Other Videos

- Warmer Appliance

- Washing & Drying Machine & Parts

- Washing Machines

- Water Heater & Components

- Electric Water Heater

- Gas Water Heater

- Heat Pump Water Heater

- Water Heater Parts

- Solar Water Heater

- Other Water Heaters

- Water Treatment Equipment

- Water Softener

- Other Household Water Treatment Equipment

- Water Dispenser

- Household Water Treatment Equipment

- Water Purifier

- Wearable Devices

- Smartwatch

- Smart Bracelet

- Smart Glasses

- Other Wearable Devices

- Wireless Paging System

- Home Audio & Video & Accessories

- Home Theatre System

- eBook Reader

- Other Consumer Electronics

- Salon Equipment

- Hair Dryer

- Hair Trimmer

- Curling Iron

- Hair Heating Cap

- Hair Perm Machine

- Hair Straightener

- Hair Steamer

- Other Salon Equipments

- Air Conditioner & Purifier & Humidifier

- Humidifier

- Dehumidifier

- Air Conditioner

- Air Purifier

- Air Cooler

- Scent Diffuser

- Other Purifiers & Humidifiers

- TV & Parts

- LCD TV

- CRT TV

- Plasma TV

- Television Parts

- TV Mount

- Other TVs

- Electric Toothbrush

- Steam Iron

- Electrical Pesticidal Utensil

- Fly Swatters

- Bug Zappers

- Household Appliances

- Pressure Vessel

- Electrical Fan & Exhaust Fan

- Electrical Fan

- Earphones & Headphones & Accessories

- Earhook Headphones

- Earphone Case

- Earphone & Headphone Accessories

- Earbuds Headphones

- Neckband Headphones

- In-Ear Headphones

- Headband Headphones

- Other Earphones & Headphones

- Audio & Sets

- Amplifier

- Karaoke Player

- Microphone

- Professional Audio

- Other Audio & Sets

- Home Theatre

- Vacuum Cleaner

- Kitchen Electronics

- Coffee Maker

- Blenders

- Electrical Kettle

- Juicer

- Rice Cooker

- Toaster

- Electric Oven

- Air Fryer

- Sandwich Maker

- Dishwasher & Disinfective Apparatus

- Ice Maker & Ice Crusher

- Bread & Cake Maker

- Induction Cooker

- Electric Pressure Cooker

- Gas Burner & Gas Stove

- Warming Tray

- Popcorn Machine

- Range Hood

- Electric Tea Maker

- Electric Skillet

- Vegetable & Fruit Purifier

- Infrared Cooker

- Coffee Grinder

- Food Processors

- Slow Cookers and Sous Vide

- Food Dehydrator

- Food Waste Disposer

- Yogurt Maker

- Microwave Oven

- Fryer

- Egg Cooker

- Other Kitchen Electronics

- Cooktops

- Food Mixers

- Bathroom Heater

- Battery & Charger

- Rechargeable Battery & Charger

- Button Cell Battery

- Primary & Dry Battery

- Bluetooth Products

- Bluetooth Dongle

- Bluetooth Gloves

- Bluetooth Headset

- Other Bluetooth Products

- Commerce & Finance Electronics

- Safe

- Money Counter

- POS Terminal & Cash Register

- Barcode Scanner

- Counterfeit Detector

- Coin Counter & Sorter

- ATM

- Vending Machine

- Payment Kiosk

- Other Commerce & Finance Electronics

- Consumer Electronics Stocks

- Disk & Cassette & Tape & Record

- Cassette & Tape

- CD & DVD Media

- Audio & Video Products

- Other Disks & Tapes

- Display & Accessories

- CRT Display

- OLED Display

- Touch Screen

- Plasma Display

- AD Player

- Monitor Stand

- LCD Module

- LCD Display

- Other Displays

- Digital Signage and Displays

- Drone & UAV & Accessories

- Drone & UAV

- Drone Accessories

- Entertainment Electronics

- Joystick & Game Controller

- Entertainment Electronics Accessories

- Handheld Game Console

- Other Entertainment Electronics

- Fax Machine

- HDMI Equipment

- HDMI Splitter

- HDMI Converter

- HDMI Cable

- HDMI Switch

- Other HDMI Equipment

- Home Appliance Parts

- Humidifier Parts

- Air Conditioner Parts

- Air Purifier Parts

- Vacuum Cleaner Parts

-

Arts & Crafts

- Antique & Collection

- Greeting Cards

- Vase

- Badge

- Souvenir

- Medal

- Metal Crafts

- Cloisonne

- Arts & Crafts Stocks

- Folk-custom Crafts

- Wooden Crafts

- Lacquer Crafts

- Balloon & Inflatable

- Calendar

- Luminous & Fluorescent Items

- Fashion Accessories

- Body Piercing

- Pendant

- Earrings

- Ring

- Bracelet & Bangle

- Sunglasses

- Jewelry Set

- Hair Ornaments

- Necklace

- Brooch

- Other Fashion Accessories

- Flower & Bonsai & Decorative Plant

- Mobile Phone Decoration

- Painting & Calligraphy

- Glass Painting

- Calligraphy

- Art Print

- Oil Painting

- Other Paintings & Calligraphies

- Crystal Crafts

- Silk & Embroidery

- Plastic & Resin Crafts

- Resin Craft

- Plastic Craft

- Pottery

- Natural Crafts

- Sticker

- Photo Album

- Reed Diffuser

- Feather & Shell Crafts

- Jade & Stone Crafts

- Key Chain

- LED Key Chain

- Silicone Keychain

- Metal Key Chain

- Leather Key Chain

- Crystal Key Chain

- Plastic Key Chain

- Other Key Chains

- Plant Plaiting

- Paper Crafts

- Bamboo Crafts

- Religion Crafts

- Other Crafts

- Basketry

- Jewelry & Accessories

- Gemstone Jewelry

- Sterling Silver Jewelry

- Gold & Platinum Jewelry

- Jewelry Parts

- Crystal Jewelry

- Jade Jewelry

- Pearl Jewelry

- Jewelry Tools

- Diamond Jewelry

- Other Jewelry

- Hair Products

- Hair Extension

- Hair Extensions & Wigs

- Hair Bulk

- Toupee

- Wig

- Hair Weaving & Hair Weft

- Other Hair Products

- Funeral Products

- Funeral Accessories

- Columbarium

- Other Funeral Products

- Coffin & Casket

- Urn

- Candle & Candle Holders

- Candle Holders

- Candle

- Leather Crafts

- Fireworks & Firecrackers

- Fountain

- Promotion Gifts

- Bottle Opener

- Coaster & Placemat

- Fridge Magnets

- Lanyard

- Promotional Mug

- Promotional Electronic Product

- Promotional Apparel

- Promotional Household Products

- Promotional Cap & Hat

- Promotional Umbrella

- Promotional Sports Supply

- Promotional Bag & Travel

- Promotional Paper Product

- Flag & Banner

- Fan

- Other Promotional Gifts

- Promotional Bracelets & Wristbands

- Festival & Party Supplies

- Easter Gifts & Crafts

- Wedding Gifts & Crafts

- Birthday Gifts & Crafts

- Halloween Gifts & Crafts

- Other Holiday Gifts & Decorations

- Christmas Supplies

- Party Supplies

- Office Gifts & Decoration

- Glass Crafts

- Porcelain & Ceramics

- Carving & Sculpture

- Ribbon

- Artificial Antique Crafts

- Artificial Crafts

- Textile & Weaving Crafts

- Fengshui Crafts

- Art Box

- Money Box

- Jewelry Box

- Music Box