Is Galvanized Roofing Sheet Good for Roofing?

As a standing seam roofing material, the galvanized sheet is an ideal roofing material for architects, designers, and homeowners, because it resists corrosion and combines durability with flexibility, making it easy to install. Many European and global producers now offer galvanized coils and sheets with tinting and moisture resistance.

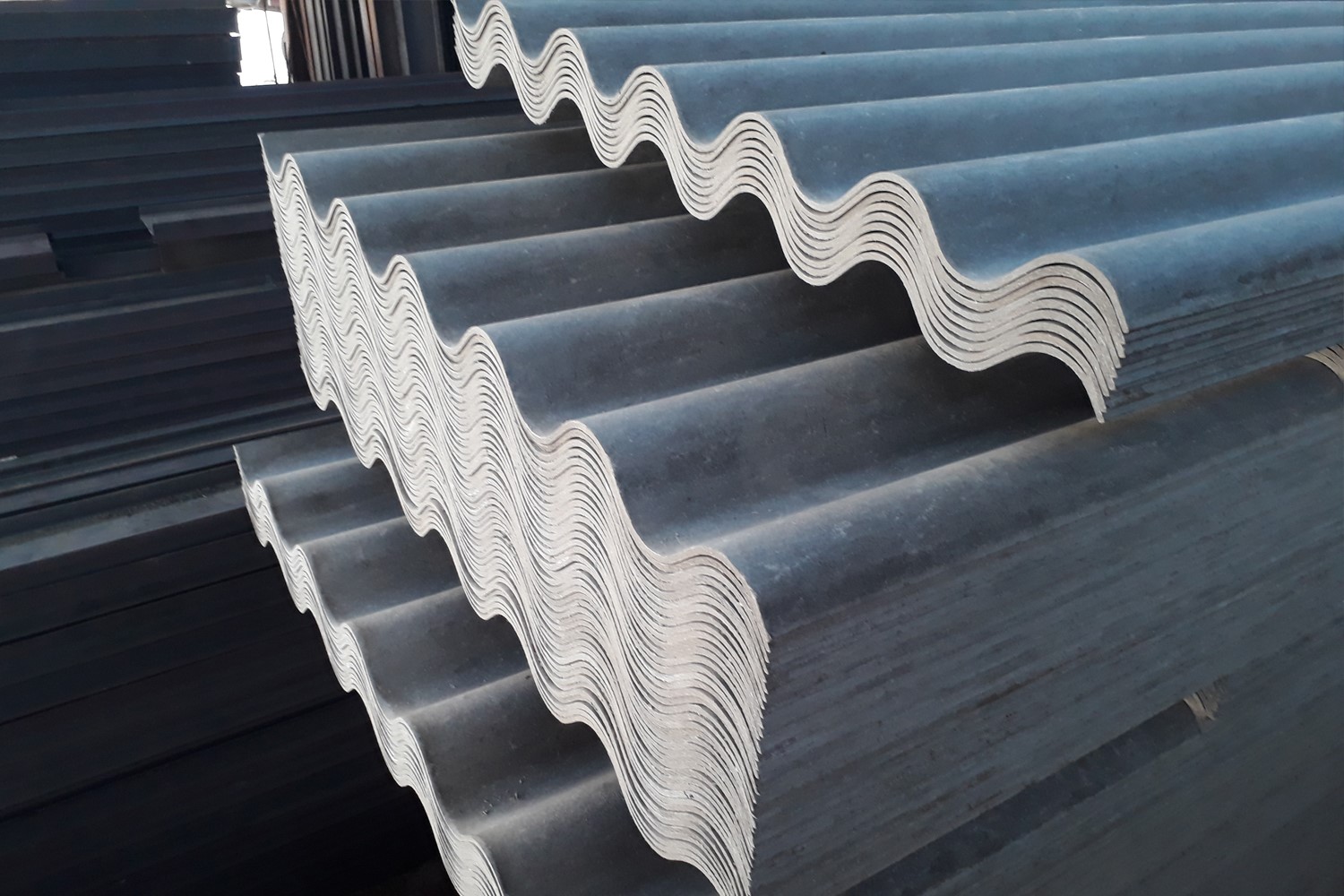

What is a Galvanized Roofing Sheet?

With a natural (bright), weatherproof finish, galvanized steel sheets can be applied to many types of roofs. As a standing seam roofing material, galvanized roofing sheets are made from aluminized steel with zinc plate. These zinc roofing sheets can be made into strips, box panels, and lock panels to cover any architectural style. Compared to other types of metal roofing products, zinc roofing sheets have a long lifespan, and provide excellent corrosion resistance. Normally these galvanized roofing sheets have a service life of more than 50 years.

How is Corrugated Metal Made?

The corrugated metal sheet is processed by roll forming. This means the raw sheet material firstly will be pulled off round metal coils and then passed through rolling dies to form the metal sheet into a corrugated sheet, after the process of forming the corrugation into a metal sheet, then will be sheared off at the correct panel length.

Types of Corrugated Metal Roofing

When it comes to the types of corrugated metal roofing, corrugated metal roofing is classified into three major types in the market, including ⅞" Corrugated, ½" Corrugated, and everything else including ribbed metal roofing panels.

⅞” Corrugated Roofing:

The most commonly used corrugated metal roofing panel is a 7/8’’ corrugated roofing sheet. This is a deep corrugated sheet that creates a shadow and offers a nice look for corrugated panels. In addition, this roofing sheet is also the strongest and most cost-effective wavy corrugated panel.

For this corrugated roofing sheet, as its deep corrugation, it can only fit for the roof with a slope of 3’’ in 12’’.

½” Corrugated Roofing:

1/2” Corrugated roofing sheet is an old roofing used a lot for old western towns. This type of corrugated roof sheet has existed for a lot of years. But as the presence of 7/8” corrugated roof sheet, the 1/2” corrugated wave sheet is not as common as it used to be due to the price higher and material less strong than 7/8”

1/2'' corrugated roofing sheets are suitable for roofing slopes at a minimum of 3'' in 12'', the panel is typically 26'' wide just remember that you need to pay for the full width of the sheet and just the coverage.

Ribbed Roofing:

The ribbed metal roofing panel has ribs with sloping sides. It forms trapezoidal-shaped voids at the side lap. It has also flat areas of the roof between raised straight lines or ridges called ribs. They are made of metal in the shape of a zig-zag. The ribs on the panels can create strong, bold lines that are aesthetically pleasing and offer a unique approach to traditional metal panels. In the early years of its invention, ribbed roofing panels were widely used in agricultural settings, but now they have been moved to more and more residential and commercial applications.

Ribbed metal roofing panels are already a favorite for homeowners, and builders, as the following benefits:

Versatility--ribbed metal panels can be used in many different ways from commercial and residential buildings to pole barns on the farm. it really can be suitable for many applications including siding fencing, and interior applications.

Easier installation--the ribbed metal panels have an exposed fastener system. That means the used hardware to secure them to the substrate on the outside of panels, so the installation is very easy, even DIY lovers can install it.

High Performance--The ribbed metal panels can also perform well under tough conditions such as rain, and extreme weather, like snow, and storms.

Tile Roof VS Metal Roof: What's the Difference

Both of these two roofing materials are popular choices for roofing refurbishment. Meanwhile, they all have their own advantages and disadvantages, so let's just have a look at the comparison of two roofing materials in order to help you better choose the right one based on your projects.

Factor | Metal Roof | Tile Roof |

Installation Cost | cost more for installation labor compared with tile roofs that require less time and labor to install. | less cost to install than metal sheets, but they are easy to break. |

Material Cost | metal roof sheets are usually a bit more expensive than tiles. | the tiles cost differently depending on the appearance of the tiles. |

Fire Resistance | metal is non-combustible, and is categorized as fire-resistance. | tiles are more like to burn when they are exposed to fire for a really long time. |

Water Resistance | the metal roof is waterproof, but the drop will make a loud sound when beat on the roof. | roof tiles are recognized for their weather resistance. they will not get corroded even in long contact with rain. |

What's the Function of Zinc Roofing Sheet?

With different metal roofing options on the market, it can be difficult to determine which one is right for your project. Metals including copper, zinc, and steel are great roofing materials that will provide you with decades of protection, and low maintenance. Zinc roofing sheet is becoming an increasingly popular roofing material due to its aesthetic and environmentally friendly properties.

Self-healing Ability:

One of the properties of zinc roofing sheets is that scratches, nicks, and minor environmental damage can self-heal over time, allowing zinc roofing to stay fresh and new for longer. The patina or protective layer that forms on the zinc called bicarbonate, not only blocks moisture and chemicals, but if a scratch or scratch occurs, it re-forms and repairs itself, making the blemish disappear. Combined with its natural corrosion resistance, this ability makes zinc ideal for harsher environmental conditions. Zinc resists a lot of damage and requires little repair over its entire life cycle.

Easy to Shape:

When added to metal alloys, zinc increases metal panels' ductility, allowing them to form unique shapes that result in beautiful and unique rooflines. Zinc can be used to create vaults and curves and is a favorite of modern architectural designers. Formed zinc does not affect its durability.

Friendly to Environment:

Zinc is a green building material with many eco-friendly properties. It starts by producing zinc, which uses less energy because it has a lower melting point than other metals. In addition, zinc is fully recyclable, and there is little waste when replacing zinc roofing sheets. During recycling, up to 95% of the original metal content can be retained and fully recycled without loss of quality or degradation. It is also non-toxic, which means the metal maintains low toxicity levels. Finally, zinc roofing sheets are more durable and last longer than other roofing materials, and galvanized roofs can last for over a century if installed properly.

Visual Appeal:

Zinc roofs feature high-quality durable materials with a unique style on Bestsuppliers that enhances the appearance of any home or building. You can use traditional seamed panels to create a more classic look or create a look that mimics modern metal tile. When untouched, zinc has a distinctive dark grey metallic appearance that is beautiful on its own. Zinc can be painted to create unique colors and styles to suit your design. No matter the style of home or building, you can complete your look with a beautiful zinc roofing sheet.

Installation of Galvanized Steel Roofing Sheet

Installation Tools you need:

1. Cutter

2. Bender

3. Measuring tape

4. Crayon marker

5. Snips

6. Roofing-grade polyurethane e sealant

7. Hammer

8. Screw gun

9. #9 Hex 1/4’’ Diameter x 1-1/2’’ Long Screws

Step 1: Take Measurements and Buy Metal Roofing Materials

Before starting a project with your roofing installation, you need to have a rough estimate of the installation area of your roof in order to well control your budget

Multiply the length of the rake by the distance from eave to eave. and double this to get a total square footage.

For special features roofs like skylights or dormers, measure them separately and add them to your total

Extra 10% quantity for talking waste into your consideration.

Step 2: Get onto the Roof

Before you get onto the roof, don’t forget to ensure your safety. Then use a metallic ladder and also get yourself tied with a durable rope to protect yourself from any risk of falling, should be even more cautious when you are walking on the roof that is slippery and has a steep. In the case you are not able to do it with your safety guaranteed, you’d better ask professional personnel to complete this task. As it’s really a risky task, will be deadly once falling off the roof.

Step 3: Remove the Old Roof

Now you are already on the roof, so what you need to do is to remove the old roof, underlayment, and vents.

Check if there will be any sign of damage below the roof, that may eventually lead to the leakage.

Remove with a hammer the remaining pieces that are sticking out after removal.

Confirm with your local government about the issue of shingle disposal.

Step4: Install Underlayment

The underlayment is a layer used for protecting the roof deck from moisture, before starting the installation of the underlayment, please ensure the roof surface is smooth, clean, and dry. Then consult the details of the product to find out which kind of underlayment you need, after that, just follow the instructions for the underlayment you bought, usually the instruction includes some important information, such as overlap requirement between rolls, which allows materials to expand and contract when the temperature changes.

Step5: Install Drip Edges and Flashing

Drip edge also called eave trim, is an essential part of diverting water away from your house and into the gutters. It’s normally attached to the roof edges with nails to cover the wood sheathing.

Use a hand seamer to bend the end of the drip edge to wrap it around the corner.

Leave a 3-inch overlap for each new piece of the drip edge and apply sealant tape at the seams.

Fasten the trim every 12 to 16 inches with roofing nails.

Then install drip edge flashing for eaves with gutter.

Step 6: Install Corrugated Metal Roofing Sheets

Now it comes with the installation of roofing sheets over drip edges. Just make sure everything is ready for this important step.

Check first with your roofing supplier for detailed metal screw nail size and also placement recommendations.

Start to overlap roofing sheets one by one at one eave first on your way up, meanwhile applying caulk or roofing sealant tape at each junction to seal the roof well.

After that, with metal roofing screw nail to fasten sheets according to manufacturer instructions.

Cut the roofing sheet to size as required using a circular saw with a compatible blade.

Step7: Install Closure Strips and Ridge Caps

Starting from the bottom with closure strips installation, and step by step go your way up, place first your closure strips along the entire length of the roof, but not so close that any of the steps hag over the roof edge. Then seal the strips with a line of tape sealant. Apply the sealant tape to the upper side of the strips so that will not be trapped underneath, check carefully there are not any gaps between the strips and the roof. Once done with the closure strips. Then install a ridge cap on top of them and press it onto the exposed tape to seal, fasten it with screws according to the manufacturer’s instructions.

When it comes to buying galvanized roofing sheets in bulk, whether it’s corrugated roof sheets, box profile roofing sheets, or tile form roof cladding sheets, Bestsuppliers will find the best suppliers for you. Simply select your roof type and let us know which type of roofing sheet you need. If you have any questions about it, contact our expert team for more information.