Mastering the Art of Edge Banding Tape: A Comprehensive Guide for Woodworking Enthusiasts

I. Introduction

Importance of attention to detail in woodworking projects

In the world of woodworking, the smallest details can have a significant impact on the final outcome of a project. That's where edge banding tape comes into play. It's an indispensable accessory that can elevate the overall quality and appearance of your woodworking creations.

Overview of edge banding tape and its role in achieving a professional finish

Whether you're a seasoned craftsman or a beginner, mastering the art of edge banding tape opens up a world of possibilities for achieving flawless finishes and professional results. In this comprehensive guide, we will explore everything you need to know about edge banding tape, from its various types and application techniques to expert tips and common mistakes to avoid. Get ready to take your woodworking skills to new heights as we dive into the intricate world of edge banding tape.

II. What is Edge Banding Tape?

Definition and purpose of edge banding tape

Edge banding tape is a narrow strip of material specifically designed to cover and protect the exposed edges of plywood, particleboard, or other wood-based panels. It serves as a finishing touch that not only conceals rough edges but also adds durability and a polished look to furniture and cabinetry.

Benefits of using edge banding tape in woodworking

Available in a variety of materials such as PVC, melamine, and acrylic, edge banding tape can be chosen to match the color and texture of the wood or to create contrasting design elements. This versatile tape is an essential component for achieving a seamless and professional appearance in woodworking projects. By understanding the concept and purpose of edge banding tape, woodworkers can harness its potential to transform their creations into stunning pieces of functional art.

III. Types of Edge Banding Tape

A. PVC Edge Banding Tape:

PVC edge banding tape is known for its flexibility, making it easy to apply to curved or irregular edges. It provides a seamless and polished finish while also protecting the edges from wear and moisture.

PVC edge banding tape is commonly used in furniture manufacturing, cabinetry, and interior design projects. When considering PVC edge banding tape, it is important to note its lower heat resistance compared to other types, so caution is needed when using heat-based application methods.

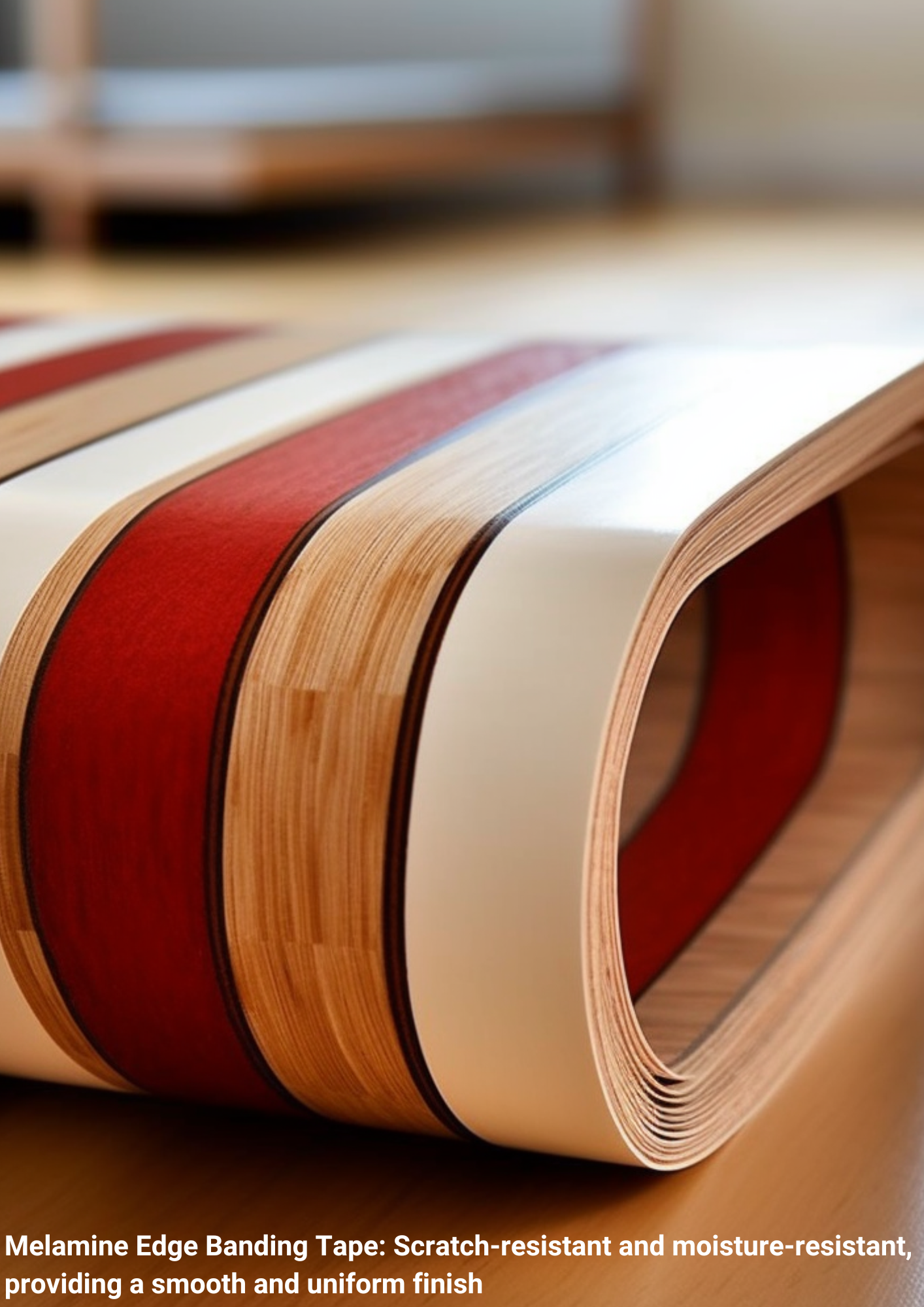

B. Melamine Edge Banding Tape:

Melamine edge banding tape, made from resin-infused paper, offers a range of features and benefits. It is highly resistant to heat, moisture, and scratches, making it an excellent choice for functional applications. Melamine edge banding tape provides a consistent and smooth finish, adding both durability and aesthetic appeal to furniture and cabinetry. It is available in a variety of solid colors and wood grain patterns, offering versatility in design options.

Melamine edge banding tape is commonly used in kitchen and bathroom cabinets, shelving units, and other high-traffic areas. However, it is important to handle melamine tape with care during installation to prevent delamination and ensure proper adhesion.

C. Acrylic Edge Banding Tape:

Acrylic edge banding tape is popular in contemporary furniture designs, retail displays, and architectural applications. Its transparent nature makes it ideal for showcasing the natural beauty of wood grains or other surface materials. However, it is essential to handle and store acrylic tape with care to avoid scratching or damage.

By understanding the characteristics, advantages, and considerations of PVC, melamine, and wood veneer edge banding tape, woodworkers can make informed decisions when selecting the most suitable option for their specific projects. Each type offers unique benefits, allowing for customized and professional finishes in woodworking applications.

IV. Advantages of Using Edge Banding Tape

A. Enhanced Durability and Protection for Exposed Edges:

Edge banding tape provides an additional layer of protection for the exposed edges of wood-based panels, such as plywood or particleboard. It acts as a shield against chips, dents, and other forms of physical damage, significantly extending the lifespan of furniture and cabinetry. By preventing moisture from seeping into the edges, edge banding tape helps to prevent warping, swelling, and other issues caused by environmental factors.

B. Improved Aesthetics and Seamless Appearance:

One of the key benefits of using edge banding tape is its ability to enhance the overall aesthetics of woodworking projects. By covering the raw edges, the tape creates a clean and polished look, concealing any imperfections or roughness. This results in a seamless and professional appearance, elevating the visual appeal of the finished piece. Whether you're working on furniture, cabinetry, or other woodworking applications, edge banding tape adds a touch of refinement and sophistication.

C. Increased Resistance to Moisture, Heat, and Wear:

Edge banding tape is specifically designed to offer enhanced resistance to common elements that can affect the durability of wood-based surfaces. It provides an additional barrier against moisture, protecting the edges from absorbing water and preventing potential damage. Furthermore, edge banding tape exhibits excellent heat resistance, ensuring that it remains intact even when exposed to high temperatures. This makes it suitable for applications where heat may be involved, such as kitchen countertops or tabletops. Additionally, the tape enhances the overall wear resistance of the edges, guarding against scratches, abrasions, and general wear and tear.

By utilizing edge banding tape in your woodworking projects, you can enjoy the numerous advantages it brings. From improved durability and protection for exposed edges to enhanced aesthetics and resistance to moisture, heat, and wear, edge banding tape is a valuable asset that contributes to the longevity and visual appeal of your creations.

V. Application Techniques

Mastering the art of applying edge banding tape is essential for achieving flawless results. We will explore different application techniques, such as heat-activated, pressure-sensitive, and adhesive-based methods. Additionally, we will provide step-by-step instructions and recommend the necessary woodworking tools and equipment for each technique.

A. Heat-Activated Edge Banding Tape:

- Steps for applying heat-activated tape: Preparing the surface, applying heat, and trimming excess tape.

- Recommended tools and precautions: Heat gun or edge banding machine, ensuring proper temperature control and applying even pressure during application.

B. Pressure-Sensitive Edge Banding Tape:

- Application process for pressure-sensitive tape: Removing backing, aligning the tape, and applying pressure for adhesion.

- Tips for achieving proper adhesion: Ensuring a clean and dry surface, using a roller or edge banding tool for better contact, and applying even pressure along the length of the tape.

C. Adhesive-Based Edge Banding Tape:

- Steps for applying adhesive-based tape: Applying adhesive to the edge or tape, aligning and pressing firmly, and trimming excess tape.

- Precautions and best practices for successful application: Ensuring a clean and dust-free surface, allowing sufficient time for adhesive activation, and using a sharp blade for trimming.

VI. Expert Tips for Flawless Results

- Surface Preparation Techniques for Optimal Bonding: Ensuring the edge is smooth, clean, and free from debris or old adhesive residue before applying the tape.

- Proper Cutting, Sizing, and Alignment of the Tape: Accurately measure and cut the tape to fit the edge precisely, aligning it evenly for a seamless appearance.

- Tips for Achieving Seamless Edges and Smooth Finishes: Applying even pressure during installation, using tools like rollers or scrapers to ensure proper adhesion and eliminate air bubbles.

- Finishing Techniques to Enhance the Overall Appearance: Sanding the edges, applying stain or finish to match the surrounding surface, and using edge banding accessories for a polished look.

VII. Common Mistakes to Avoid

- Identification and Prevention of Common Errors: Common mistakes such as improper surface preparation, inadequate adhesive activation, or incorrect alignment, and solutions to avoid or rectify these issues.

- Troubleshooting Tips for Addressing Issues during Application: Quick fixes for problems like peeling edges, bubbles, or uneven adhesion that may arise during or after application.

VIII. Maintenance and Care

- Cleaning and Maintaining Edge Banding Tape: Proper cleaning techniques to remove dust, dirt, or stains without damaging the tape or underlying surface.

- Repairing Damaged or Peeling Edges: Steps to fix damaged or peeling edge banding tape, such as reactivating adhesive, applying touch-up stain or finish, or replacing the tape if necessary.

- Long-Term Preservation of Edge Banding Tape: Tips for maintaining the appearance and integrity of the tape over time, including avoiding excessive moisture or heat exposure and proper handling during use or transportation.

IX. Where to Find Quality Edge Banding Tape

As professionals working for our esteemed company, we take pride in offering the best edge banding tape solutions to our customers. When it comes to sourcing high-quality products, we recommend visiting our website, www.bestsuppliers.com. Our platform is a trusted marketplace that showcases a vast selection of top-notch edge banding tape from reputable manufacturers and suppliers.

At www.bestsuppliers.com, you'll find a diverse range of edge banding tape options to suit your specific project requirements. We understand the importance of quality in woodworking projects, which is why we collaborate with renowned suppliers known for their commitment to excellence. Our website allows you to explore various types, colors, and sizes of edge banding tape, ensuring you have the freedom to choose the perfect match for your woodworking needs.

Visit our website, today to browse our extensive collection of top-quality edge banding tape. With our expertise and dedication to sourcing the best products, you can confidently select the ideal edge banding tape to achieve flawless results in your woodworking endeavors.

X. Conclusion

In conclusion, edge banding tape is a valuable accessory that brings numerous benefits to woodworking projects. It enhances durability, improves aesthetics, and provides resistance to moisture, heat, and wear. By following the recommended application techniques, utilizing expert tips for flawless results, avoiding common mistakes, and maintaining the tape properly, woodworkers can achieve professional-looking finishes that stand the test of time. Remember to source edge banding tape from www.bestsuppliers.com, considering the specific project requirements. With the knowledge gained from this guide, readers are encouraged to apply their newfound expertise in their woodworking endeavors, elevating their craftsmanship to new heights.