The Power of Rivets: A Strong and Reliable Fastening Solution

In the world of construction, manufacturing, and various industries, finding reliable and robust fastening solutions is of utmost importance. Among the plethora of options available, rivets stand out as a powerful, versatile, and time-tested method for joining materials securely. In this comprehensive blog article, we will delve into the fascinating world of rivets, exploring their applications, benefits, and the reasons why they have become a preferred choice for professionals across different sectors.

What are Rivets?

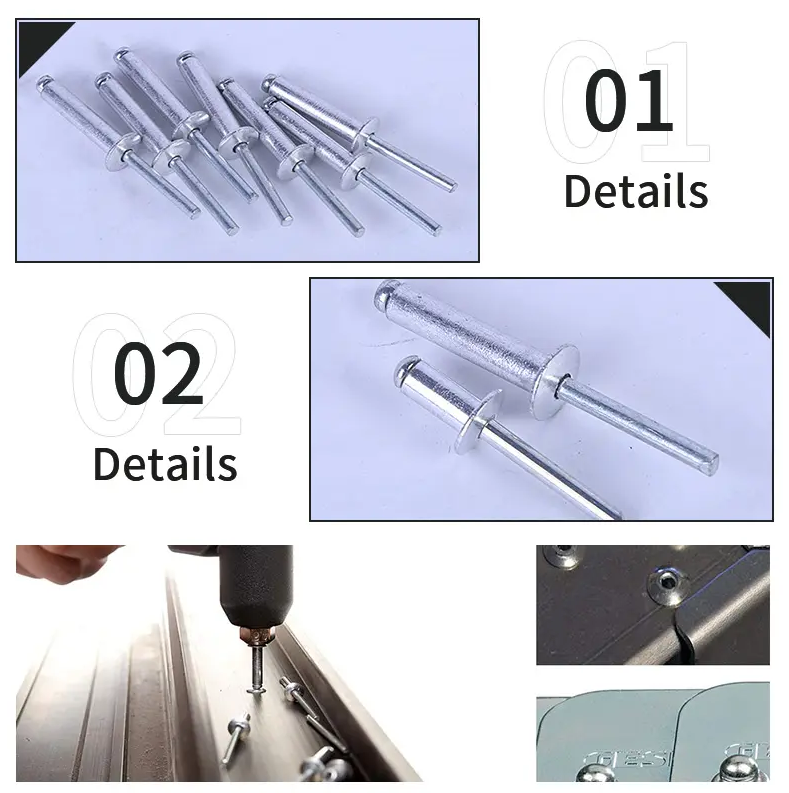

Rivets are mechanical fasteners that create permanent joints between two or more materials. Consisting of a smooth cylindrical body with a head on one end and a tail on the other, rivets are designed to create a robust and durable connection. This connection is achieved by inserting the rivet through pre-drilled holes in the materials to be joined and then deforming or compressing the tail end to form a secure and tight bond.

Rivets have been in use for centuries Their simplicity, reliability, and effectiveness have made them an enduring fastening solution throughout history. Over time, advancements in materials and manufacturing techniques have led to the development of various types of rivets, each designed to cater to specific applications and requirements.

Rivets can be made from different materials, including aluminum, steel, stainless steel, copper, and more. The choice of material depends on factors such as the type of materials being joined, the desired strength, corrosion resistance, and environmental considerations.

In the following sections, we will explore the different types of rivets available, their specific advantages, and the wide range of applications where rivets play a vital role. Whether you are a professional in the construction industry or a manufacturer seeking reliable fastening solutions, understanding the world of rivets will equip you with the knowledge to make informed decisions for your projects.

What are the Advantages of Rivets?

- Strength and Load-bearing Capacity: Rivets excel in providing high strength and load-bearing capacity, making them suitable for heavy-duty applications. Unlike screws or nails that rely on threads or friction, rivets create a strong and permanent bond, ensuring the joint can withstand significant loads and vibrations.

- Reliability and Durability: Once properly installed, rivets offer excellent resistance to loosening, corrosion, and wear. This reliability and durability make them an ideal choice for structures that need to withstand harsh environments, extreme temperatures, or prolonged exposure to moisture.

- Improved Aesthetics: Rivets offer a clean and streamlined appearance compared to other fasteners. With no protruding threads or heads, they contribute to a sleek and professional finish, making them popular in industries where aesthetics matter, such as automotive, aerospace, and architectural design.

What are the Types of Rivets?

- Solid Rivets: Solid rivets are the original and most basic type of rivets. They consist of a single piece of metal that is manually installed and formed into a permanent joint. Solid rivets are known for their exceptional strength and reliability, making them suitable for heavy-duty applications, structural assemblies, and metal fabrication.

- Blind Rivets: Blind rivets, also known as pop rivets, are versatile fasteners that can be installed from one side of the joint, without requiring access to the opposite side. This makes them ideal for applications where the joint is not easily accessible or when only one side is accessible. Blind rivets are widely used in industries such as automotive, electronics, and aviation.

- Structural Rivets: Structural rivets are specifically designed for high-strength applications where maximum load-bearing capacity is required. They provide exceptional shear and tensile strength, making them suitable for heavy machinery, bridges, and other critical structures. Structural rivets are often made from high-strength materials like aluminum alloy or stainless steel.

What are the Applications of Rivets?

- Automotive Industry: Rivets play a crucial role in automotive manufacturing, providing secure joints for body panels, structural components, and interior trim. Their strength, durability, and resistance to vibration make them ideal for withstanding the rigorous demands of the automotive industry.

- Aerospace Industry: In the aerospace sector, where safety and reliability are paramount, rivets are extensively used for aircraft assembly. From fuselage construction to wing components, rivets provide robust and fail-safe connections, ensuring the structural integrity of the aircraft.

- Construction and Infrastructure: Rivets find applications in the construction and infrastructure sectors, including bridges, buildings, and heavy machinery. Their ability to withstand heavy loads, extreme weather conditions, and long-term durability make them a preferred choice for critical structural connections.

How to Choose the Right Rivets?

When it comes to choosing the right rivets for your specific application, it's essential to consider several factors to ensure optimal performance, reliability, and longevity. The selection process involves evaluating the materials being joined, load-bearing requirements, environmental conditions, and the preferred installation method. By carefully considering these aspects, you can make an informed decision and choose the perfect rivets for your project.

Materials Being Joined:

First and foremost, consider the materials you need to join. Different materials have varying properties, such as hardness, thickness, and composition, which can impact the choice of rivets. For example, if you're joining two metal sheets, you may opt for solid aluminum rivets for their strength and compatibility with metal substrates. On the other hand, if you're joining metal to plastic, a blind rivet with a plastic mandrel can provide a secure and non-corrosive connection.

Load-Bearing Requirements:

The load-bearing capacity of rivets is crucial, especially in applications that experience significant forces or vibrations. Consider the expected loads and stresses that the rivets will endure. If you're working on heavy machinery or structural assemblies, structural rivets made from high-strength materials like stainless steel or alloy are recommended. These rivets offer exceptional shear and tensile strength, ensuring the joint can withstand demanding conditions and maintain structural integrity.

Environmental Conditions:

The environment in which your rivets will be exposed should also be taken into account. Factors such as temperature fluctuations, moisture, chemicals, and UV exposure can impact the performance and longevity of rivets. If your project requires resistance to corrosion, consider using rivets made from stainless steel or materials with appropriate coatings. For applications exposed to extreme temperatures, high-temperature-resistant rivets are available. Understanding the environmental conditions will help you select rivets that can withstand the specific challenges of your project.

Installation Method:

Another critical aspect to consider is the installation method. The choice of rivets depends on the available access for installation. If you have access to both sides of the joint, solid rivets can be manually installed and formed using tools such as rivet guns or hammers. On the other hand, if you have limited or one-sided access, blind rivets are the ideal choice. They can be installed from one side, and the mandrel is subsequently pulled to create a secure connection. Blind rivets offer convenience and efficiency in situations where accessing both sides of the joint is impractical or impossible.

Where to Buy the Best Quality Rivets?

At Bestsuppliers.com, we understand the importance of choosing the right rivets for your specific needs. As a trusted supplier of rivets, we offer an extensive range of high-quality options designed to meet various industry requirements. Our knowledgeable team is ready to assist you in selecting the ideal rivets, considering the materials, load-bearing demands, environmental conditions, and installation method. With our expertise and exceptional product selection, you can have confidence in choosing the best rivets for your project.

By partnering with Bestsuppliers.com, you not only gain access to a wide range of top-quality rivets but also benefit from our commitment to excellent customer service and industry expertise. We are dedicated to helping B2B businesses like yours make informed decisions, ensuring the success and durability of your projects.

Conclusion

Rivets have stood the test of time as a reliable, strong, and versatile fastening solution. From the automotive and aerospace industries to construction and manufacturing, their benefits are undeniable. As you embark on your next project, consider the power of rivets in providing secure, durable, and efficient joints that withstand the challenges of your industry.

Choose Bestsuppliers.com as your trusted supplier for high-quality rivets and experience the difference our expertise can make. Elevate the performance and reliability of your assemblies with the right rivets tailored to your specific requirements. Contact us today to explore our extensive product range and get personalized guidance in choosing the perfect rivets for your project.