Types of Screwdrivers and Functions [with Pictures]

![Types of Screwdrivers and Functions [with Pictures]](https://cdn.bestsuppliers.com/upload/20230208/2023020816165564887.jpg)

Screwdrivers as an important component of hand tools are used to install and loosen screws. Screwdrivers are used wherever there are screws. They are widely used in daily life. Bestsuppliers.com will introduce different types of screwdriver tools, how to use screwdrivers safely, and tips for maintaining screwdrivers, so that everyone can choose a screwdriver that suits them.

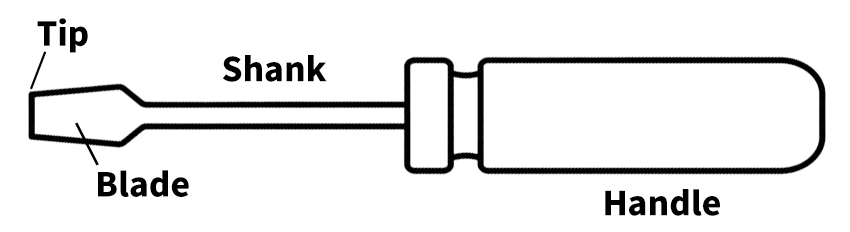

Part of Screwdrivers

A screwdriver is one of the simplest tools in hand tools for sale. Wholesale screwdrivers consist of four important parts:

1. Ergonomic handle

Ergonomic design

The screwdriver handle is the part that people hold and turn when using a screwdriver. From the summary of user experience, there are two of the most important points. It conforms to the shape of the human hands. In other words, the screwdriver's handle fits the shape of the human hands and is comfortable to hold. Therefore, most screwdrivers consider ergonomic handles in modern life.

Anti-skid effect

When a screwdriver is used in an industrial environment, the screwdriver is easily contaminated by oil, so the non-slip design of the screwdriver handle is very necessary to ensure work efficiency in the industrial environment.

Many screwdrivers on the market optimize the design of the handle according to people's needs, such as adding particles and grooves to the handle to increase the coefficient of friction and enhance the anti-slip function. Also, use a rubber material or other method to ensure that the screwdriver handle is non-slip.

2. Screwdriver Shaft (Shank)

The screwdriver's Shank is the part that transmits force during use. There are three criteria for a good screwdriver shaft.

The screwdriver's shank has sufficient hardness and toughness.

The screwdrives' Shank has better impact resistance.

3. Screwdriver blades

The blade is the root of a screwdriver. There are two criteria for judging the quality of a screwdriver head.

The hardness of the blade

Like the shaft, it is best to choose a material with high hardness, good toughness, and resistance to rust and wear as the tip material, which can increase the use time of the screwdriver.

Coatings on screwdriver bits help extend life.

end-to-end accuracy

The accuracy of the screwdriver bit refers to how well it matches the size and width of the screw head slot.

In order to improve the accuracy of the screwdriver, it is necessary to improve the matching degree of the drill bit and the screw rod.

Plating is applied to the head of the screwdriver. Generally, the color of the screwdriver will be different due to the different plating treatments. Plated for improved friction and fit.

4. screwdriver heads of different shapes.

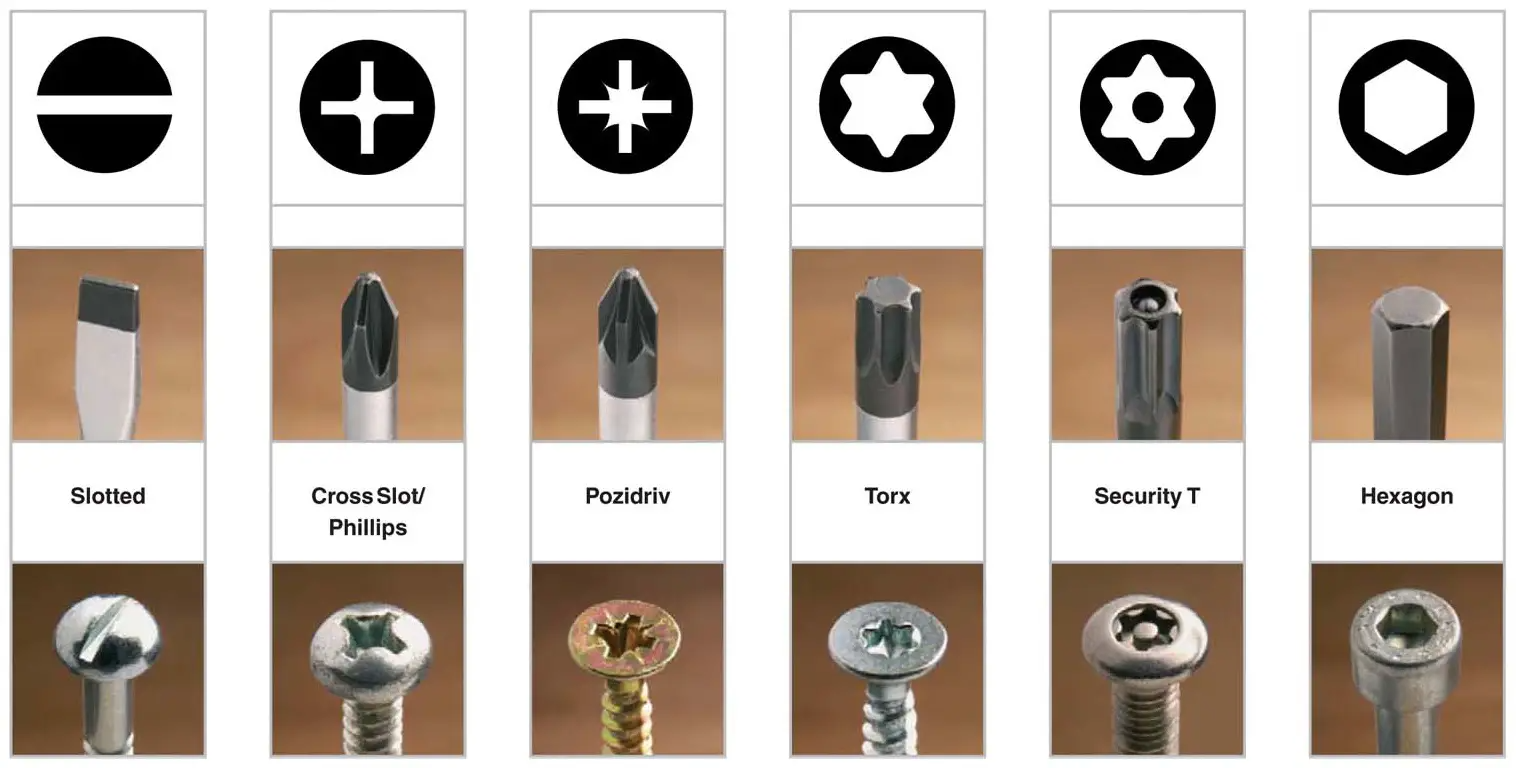

Using the wrong tool can strip and damage the screw, matching the correct screwdriver to the screw can save time and money, here is a quick overview of some of the more common screwdrivers available and how they are used.

What are the 8 most common types of screwdrivers?

Types of screwdrivers are generally distinguished from each other according to the shape of the blade head. Generally, flat-head screwdrivers and Phillips screwdrivers are most commonly used in households. The following are the more common screwdrivers in life, including Slotted Screwdrivers and Phillips screwdrivers.

The picture shows some examples of the types of screwdrivers used for the corresponding screws and the design of the screwdriver head

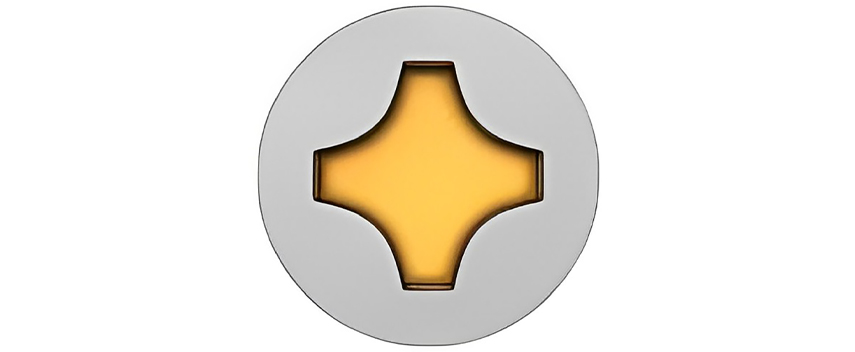

1. Phillips-Head Screwdrivers: why is it called a Phillips screwdriver?

Phillips-Head screwdriver was invented by Henry Phillips in the 1930s, So this screwdriver is named after him. Phillips screwdrivers are more common than Flathead/regular screwdrivers, Phillips-Head screwdrivers’ blade notch resembles a cross. A Phillips-head screwdriver has a four-star point on the tip that fits into a shallow cross-shaped depression in the corresponding screw. This design allows the user to apply more torque than a flat-head screwdriver can.

2. Electric Screwdrivers & Power Screwdrivers

Electric screwdrivers also known as power screwdrivers, An electric screwdrivers & power Screwdrivers use an electric motor instead of manual installation and removal of screws, usually a combination screwdriver. An electric screwdriver is an electric tool for installing and rotating screws. This tool is mainly used in assembly lines and is one of the necessary tools for most production factories. In many workplaces and homes, hand screwdrivers have been replaced by more modern and versatile tools like power drills, because they are faster, easier, and also drill holes.

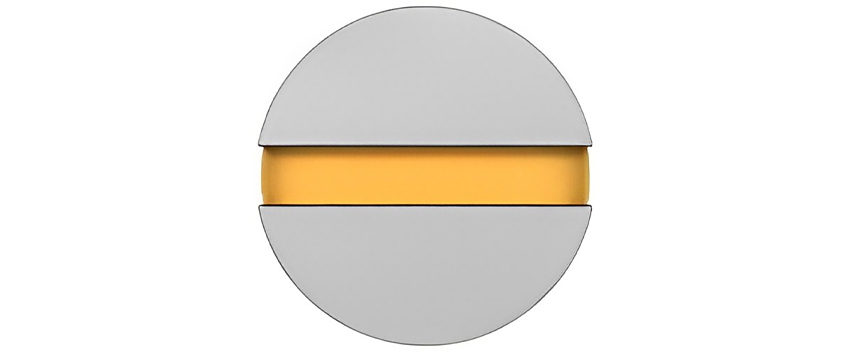

3. Slotted Screwdrivers (Slot head screwdriver (Flathead/regular screwdriver).

Slotted Screwdrivers are one of the most common screwdrivers in life. A slotted head screwdriver consists of a flat blade that fits into the single slot of a conventional screw. The specification of a flat-blade screwdriver is generally indicated by the width of the head of the blade* the length of the blade, for example: 3*75MM means that the width of the head of the blade is 3MM, and the overall length of the blade is 75MM. But the length of the whole screwdriver is not 75MM, because 75MM does not include the length of the handle.

4. Multi-bit screwdrivers & Interchangeable Head

Electric screwdrivers have interchangeable heads but are operated manually. 4. Multi-bit screwdrivers & Interchangeable Heads' main benefit is toolbox flexibility and less clutter. Some models offer accessories to organize and store bits so you don't lose any parts.

5. Screwdriver Sets

Screwdriver Sets that separate the screwdriver head from the handle. When installing different types of screws, you only need to replace the screwdriver head. The screwdriver heads of each device can be interchanged, so you don’t need to bring a lot of screwdrivers. The advantage is that it can save space, but it is easy to lose the screwdriver bit, usually, we will pack it with a toolbox.

6. Pozidriv screwdriver

Pozidriv screwdriver shape of the cutter head of the PZ is like a PZ screwdriver. This screwdriver is a variant of Phillips. The specifications are generally indicated by PZ numbers. It can withstand greater torque and is not easy to slip. PZ0-PZ3 corresponds to the same tool holder diameter as the cross, which are 3mm, 4.5 or 5mm, 6mm, and 8mm respectively.

7. Hex key or hex wrench

The hex key or hex wrench, is an L-shaped tool with a hexagonal cross section. These are commonly included with DIY furniture pieces. Hex Keys are commonly sold in sets. Precision hex screwdrivers are great for turning small screws on sensitive electronics, the specification of the inner hexagonal screwdriver is generally expressed by H+ the length of the opposite side, and the unit of the length of the opposite side is MM. The commonly used specifications are H1, H1.5, H2, H2.5, H3, H4, H5, H6 etc.

8. Torx Screwdriver

Torx keys are similar to hex keys and have the same L-shape, except this tool has a six-point, star-shaped section. The Torx screwdriver provides a secure grip on the fastener head.

8 types of screwdrivers are the most common in daily life: In addition to the styles of these screwdrivers introduced above, there are many different types of screwdrivers: inner cross screwdriver, five-pointed star screwdriver, U-shaped screwdriver, triangle screwdriver, Y-shaped screwdriver, etc. While these are the most common screwdrivers, there are several other types for different jobs. Browse this site to see different types of screwdrivers.

How to use a screwdriver safely.

Every screwdriver has its function, and screwdrivers are probably the most misused and abused tools in the workplace. Misuse can impair the effectiveness of the screwdriver by breaking the screwdriver handle, deforming the screwdriver handle, or dulling the tip of the screwdriver. It makes people easy to be injured when using the screwdriver correctly. In order to prevent the user from being injured and maintain the use effect of the screwdriver, we have given a detailed use procedure:

Make the pilot hole

Start by making a pilot hole for the screw in the wood and sheet metal. When driving a screw into the wood it is best to drill a pilot hole first, without a pilot hole the screw will tend to follow the grain of the wood causing the screw to bend. So the pilot holes make sure you drive the screws straight in.

Mounting screws

Pilot holes prevent wood and sheet metal from splinting when screwing in. For small screws in wood and sheet metal, use a punch and an awl to make a pilot hole. For larger-size screws and all hardwood screws, drill a pilot hole with some kind of drilling tool. When using a screwdriver, do not use the screwdriver as a punch, wedge, clamp, or pry bar and need to keep the tip of the screwdriver clean and sharp so that you can get a firm grip on the screw tip, if you find that the tip of the screwdriver is a bit rounded or chipped, Please avoid it. At the same time, it is necessary to keep the handle of the screwdriver clean and intact for a firm grip and to prevent slipping.

Never hold the screw you're working on in your hands, always keep it on the bench or in a vise. Place the screw on the driver's head and use the fingers of one hand to bring the screw and head together. While turning clockwise, apply light pressure to the driver until the screw engages the wood. Keep your screwdrivers in your toolbox or work bag, out of pockets, to prevent getting scratched by the screwdriver head.

continue to use. When the screw's threads engage the wood, move the finger holding the screw over the shank of the screwdriver. Using these fingers as a guide, align the tip directly with the screw. Apply enough pressure to the drive to keep it in the slot.

Where to source screwdriver tools

It is easy to find a manufacturer of screwdrivers, but it is very difficult to find a 100% screwdriver manufacturer with a competitive price and guaranteed quality.

Perfect Supply Chain Management

Bestsuppliers.com is a leading procurement platform in China, we have strong high-quality factory resources, and have reached a long-term cooperation with screwdrivers Factories: we have long-term assessment standards for them, including commodity delivery Cycle punctuality rate, commodity output evaluation and advantageous price, etc.

multilingual communication

90% of Chinese factories can't speak English, they are better at production and processing. But Bestsuppliers.com international business team is proficient in written and spoken English, Spanish, Russian, Arabic, and other languages. Most of them have overseas education experience. They can fully understand your needs and help establish good communication with Chinese factories.

Quality Inspection Standard

Bestsuppliers.com has a professional quality inspection team: we have a series of quality inspection tools and have resumed a professional inspection laboratory. Quality inspectors have received professional technical training. They will directly participate in the factory's production site and help overseas buyers supervise the production process. , strictly control the quality.

Tell us your purchasing requirements. We guide you patiently until your product is manufactured and delivered. Welcome to inquire on our website, you can also contact us by email, the fastest way is to initiate a conversation with us directly on WhatsApp.

Email Address: inquiry@bestsuppliers.com

Whatsapp Number: +86 17326049340