Understanding Welding Rods: A Comprehensive Guide For Enthusiasts

INTRODUCTION

Welding is a widely used industrial process that involves heating two metal pieces to the point of melting and then using a filter material, known as a welding rod, to join them together. The weld produced by this process is strong, durable, and corrosion-resistant, making it ideal for a wide range of applications.

If you're new to welding, choosing the right welding rod can be a daunting task. There are many different types of welding rods available, each designed for a specific purpose. In this guide, we'll take a closer look at welding rods and help you choose the right one for your welding project.

I. Types of Welding Rods:

- Carbon Steel Welding Rods: These welding rods are designed for welding carbon and low-alloy steels and are the most common type of welding rod used in welding applications. They are inexpensive, easy to use, and produce strong welds in most applications.

- Stainless Steel Welding Rods: As the name suggests, these welding rods are designed for welding stainless steel. Due to the chromium content in these rods, they resist corrosion better than other steel types. These welding rods are particularly useful for food-grade and medical-grade applications.

- Aluminum Welding Rods: These welding rods are designed for welding aluminum and aluminum alloys. They produce a strong weld and are easy to use with both TIG and MIG welders.

- Cast Iron Welding Rods: These welding rods are designed for welding cast iron, which can be difficult due to its brittle nature. These rods are designed to be strong and dependable, producing a high-quality weld in cast iron.

- Copper Alloy Welding Rods: These welding rods are designed for welding copper alloys and are used in gas tungsten arc welding (GTAW) applications.

II. How to Choose The Right Welding Rod?

To choose the right welding rod for your project, consider the type of metal you'll be welding and the thickness of the metal. In general, thicker metals require welding rods with more penetrating power. Also, consider the type of welding you'll be doing, as some welding processes require the type of welding rods.

While choosing the right welding rod, there are certain factors that need to be kept in mind in order to ensure that the welding process is smooth and the end product is of good quality. Factors such as the type of metal, thickness of the metal, and the welding process to be employed, all play a crucial role in determining the ideal welding rod.

A. Type of Metal:

The type of metal you’ll be welding is a primary factor to consider when choosing the right welding rod. The welding rod should be able to complement the properties of the metal you are working with.

For instance, Stainless Steel welding rods are the most suitable option for welding Stainless Steel because of the chromium content in these rods, they resist corrosion better than other steel types. In contrast, Carbon Steel welding rods are the most commonly used welding rods for welding carbon and low-alloy steels because they are inexpensive, easy to use, and produce strong welds in most welding applications.

B. Welding Rod sizes:

The thickness of the metal that is being welded is also important when choosing the right welding rod. In general, thicker metals require welding rods with more penetrating power. In case the welding rod does not have enough penetrating power, the weld produced will not be strong, and there could be issues of porosity.

For instance, in the case of welding thicker metals, it is recommended to use E6010 or E7018 welding rods that come with slightly more penetrating power. On the other hand, if the welding is being done on thinner metals, it is better to use E6013 welding rods that come with a lesser penetrating power.

C. Welding Process:

Another key factor to consider is the type of welding process that will be employed. There are different welding processes, TIG welding, MIG welding, and Stick welding. Different welding processes have their specific welding rod requirements.

For example, TIG welding requires a specific type of welding rod known as a TIG rod. TIG welding rods are made up of non-consumable tungsten and are used with an external filler material. Similarly, MIG welding requires a specific type of welding rod or wire such as ER4043 wire or ER70S-6 wire. These welding rods, in particular, are suitable for welding thin sheets of aluminum and other non-ferrous metals.

Choosing the right welding rod depends on the type of metal, the thickness of the metal, and the welding process to be employed. Understanding these factors will enable you to select an appropriate welding rod that matches your specific welding needs. Remember, a welding job is only as good as the welding rod employed. It is therefore important to give equal consideration to the choice of welding rod as other aspects of welding.

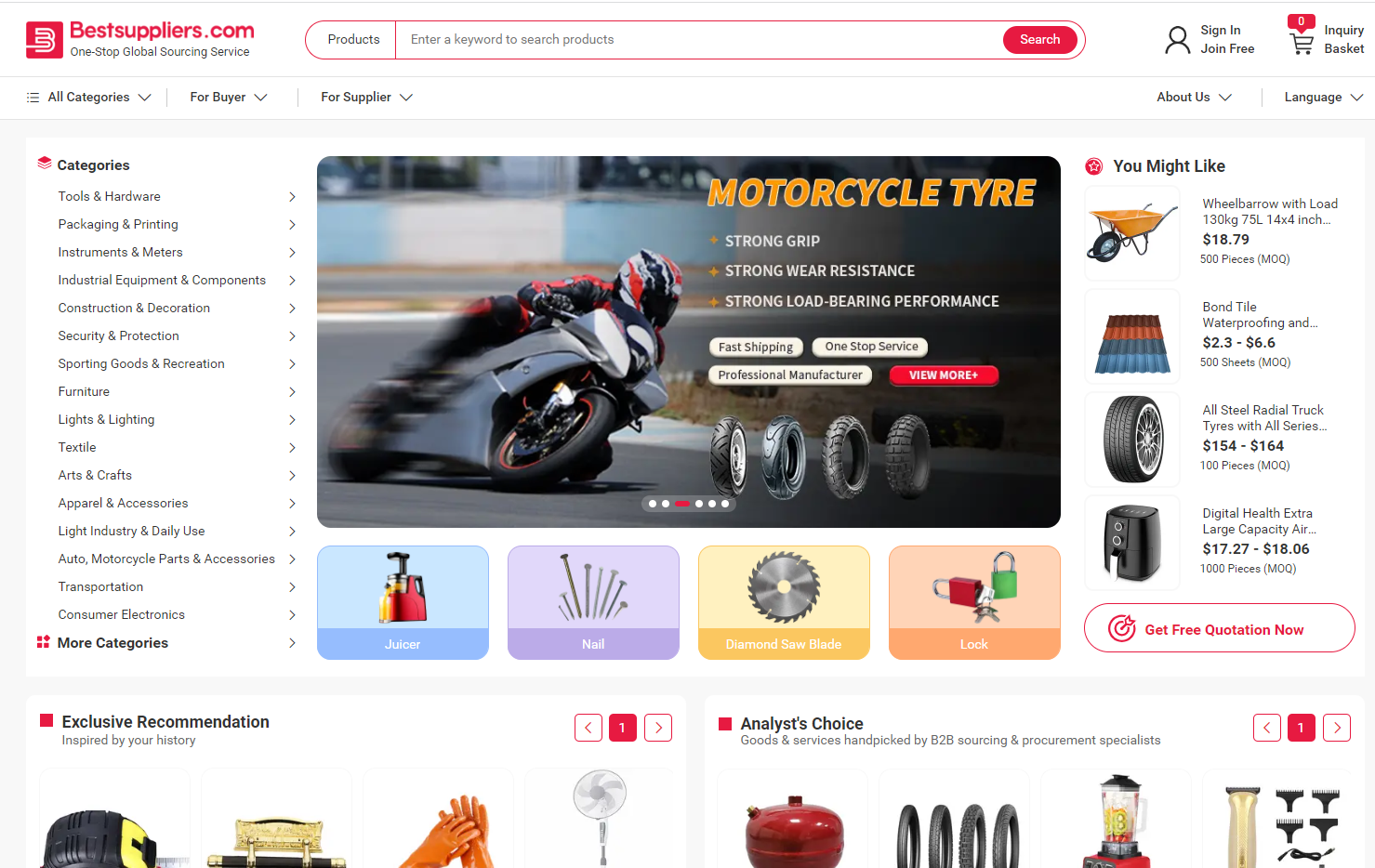

III. Where to Find the Best Welding Rods?

When it comes to finding the best quality welding rod for your projects, it's essential to rely on reputable suppliers that offer a wide range of options. As professionals working for our esteemed company, we take pride in offering the best welding rods to our customers. Our platform is a trusted marketplace that showcases a vast selection of top-notch welding rods from reputable manufacturers and suppliers.

Our welding rods are sourced from reliable manufacturers with a proven track record of producing high-quality welding rods. We ensure that each welding rod is tested for its performance and durability before making it available to our customers.

What sets us apart from other welding rod suppliers is our commitment to customer satisfaction. We offer competitive pricing, timely delivery, and excellent customer support. We understand that every welding project has its unique requirements, and our knowledgeable and experienced team is always ready to assist you in choosing the right welding rod, ensuring that your project is completed successfully.

Conclusion

When it comes to welding, choosing the right welding rod can make all the difference. From the type of metal and thickness of the metal to the welding process being used, there are several factors to consider when selecting the appropriate welding rod.

At our company, we understand the importance of using the right welding rod for each task. Our website offers a wide range of welding rods, from carbon steel welding rods to stainless steel welding rods, and aluminum welding rods to cast iron welding rods, to suit all your welding needs.