What is the Difference Between Stainless Steel Coils and Color Coated Aluminum Coils?

Coil, as a finished material, is rolled and then coiled into sheets or strips. According to current products and international standards, coils are classified as steel coils, stainless steel coils, aluminum coils, etc. Bestsuppliers will then share the following information with you.

What are Stainless Steel Coils?

Stainless steel coils are long, continuous strips of stainless steel that have been rolled and coiled up. They are typically made from high-quality grades of stainless steel, such as 304 or 316, which have excellent corrosion resistance, high strength, and good formability. These products can be finished with a variety of surface treatments, including brushed, polished, or matte finishes, to enhance their appearance and provide additional protection against corrosion. As one of the most demanded raw materials, stainless steel coils can be produced in a variety of thicknesses, widths, and lengths, depending on the specific application. They are often supplied in large rolls and can be cut to size and shape as needed. For years stainless steel coils have been widely used in the industrial field, including construction, automotive, and manufacturing. At the same time, they can be used to make a variety of products, including kitchenware, cutlery, medical equipment, and electronic components. Bestsuppliers has been exporting high-quality stainless steel sheet coils for almost 30 years. Please contact our professional team if you require steel coils for wholesale.

Types of Stainless Steel Coils

There are several types of stainless steel coils, each with its own unique characteristics and properties. Some of the most common types of stainless steel coils include:

Austenitic Stainless Steel Coils

Austenitic stainless steel coils are the most common type of stainless steel coil. They are highly corrosion-resistant and have excellent formability, making them suitable for a wide range of applications. Some of the most common grades of austenitic stainless steel coils include 304, 316, and 321.

Ferritic Stainless Steel Coils

Ferritic stainless steel coils are characterized by their high levels of chromium and low levels of carbon. They are typically less corrosion-resistant than austenitic stainless steel coils but are highly resistant to stress corrosion cracking. Some of the most common grades of ferritic stainless steel coils include 409 and 430.

Martensitic Stainless Steel Coils

Martensitic stainless steel coils are characterized by their high levels of carbon and low levels of chromium. They are highly resistant to wear and abrasion and are commonly used in applications such as cutlery and surgical instruments. Some of the most common grades of martensitic stainless steel coils include 410 and 420.

Duplex Stainless Steel Coils

Duplex stainless steel coils are characterized by their high levels of both chromium and nickel, as well as their high strength and corrosion resistance. They are commonly used in applications that require high corrosion resistance and strength, such as chemical processing and offshore oil and gas production. Some of the most common grades of duplex stainless steel coils include 2205 and 2507.

Benefits of Stainless Steel Coils

Stainless steel coils offer a range of benefits compared to other types of materials. Here are some of the key benefits of stainless steel coils:

- Corrosion resistance: Stainless steel coils are highly resistant to corrosion, making them suitable for use in harsh environments, such as marine and chemical processing applications.

- Strength: Stainless steel coils have high strength, which makes them suitable for use in applications that require structural stability and support.

- Durability: Stainless steel coils are durable and long-lasting, which means they require less maintenance and have a longer lifespan than other materials.

- Formability: Stainless steel coils are easy to form and shape, making them suitable for a wide range of applications.

- Hygiene: Stainless steel is a hygienic material that is easy to clean and maintain, making it suitable for use in applications that require high levels of cleanliness, such as in the food and beverage industry.

- Recyclable: Stainless steel is 100% recyclable, which means it can be reused and repurposed at the end of its lifespan, making it an environmentally friendly choice.

- Aesthetic appeal: Stainless steel coils have a sleek and modern appearance that can enhance the aesthetic appeal of a wide range of applications, such as architectural and decorative uses.

What Are Color-Coated Aluminum Coils?

Color coating is a process of applying a pigmented coating to a material such as metal, plastic, or wood, to improve its appearance and provide protection against corrosion, weathering, and other forms of damage. Color-coated aluminum coils are surface-coated with a protective layer to enhance their aesthetic appearance and durability. The coating is typically applied using a coil coating process, in which the aluminum coil is unwound, cleaned, treated, and coated with paint or a protective layer before being rewound into a coil. It is commonly used in aluminum plastic plates, aluminum veneers, aluminum ceilings, etc.

What is the Difference Between Color Coated Coils and Stainless Steel Coils?

Color-coated aluminum coils and stainless steel coils are two different materials with distinct characteristics and properties. Here are some of the key differences between color-coated aluminum coils and stainless steel coils:

- Material: Color-coated aluminum coils are made from aluminum, while stainless steel coils are made from steel.

- Corrosion resistance: Both color-coated aluminum coils and stainless steel coils are corrosion-resistant, but stainless steel has a higher resistance to corrosion than aluminum.

- Strength: Stainless steel coils have higher strength than aluminum coils, making them more suitable for applications that require structural support.

- Formability: Aluminum coils are easier to form and shape than stainless steel coils, making them more suitable for applications that require complex shapes and designs.

- Aesthetic appeal: Both color-coated aluminum coils and stainless steel coils offer a range of aesthetic options, but the appearance of each material is distinct. Aluminum coils are available in a wide range of colors and finishes, while stainless steel coils offer a sleek and modern appearance.

- Weight: Aluminum coils are lighter in weight than stainless steel coils, making them easier to handle and install.

- Cost: Color-coated aluminum coils are generally less expensive than stainless steel coils, making them a more cost-effective option for some applications. However, the cost difference may depend on the specific application and the size of the project.

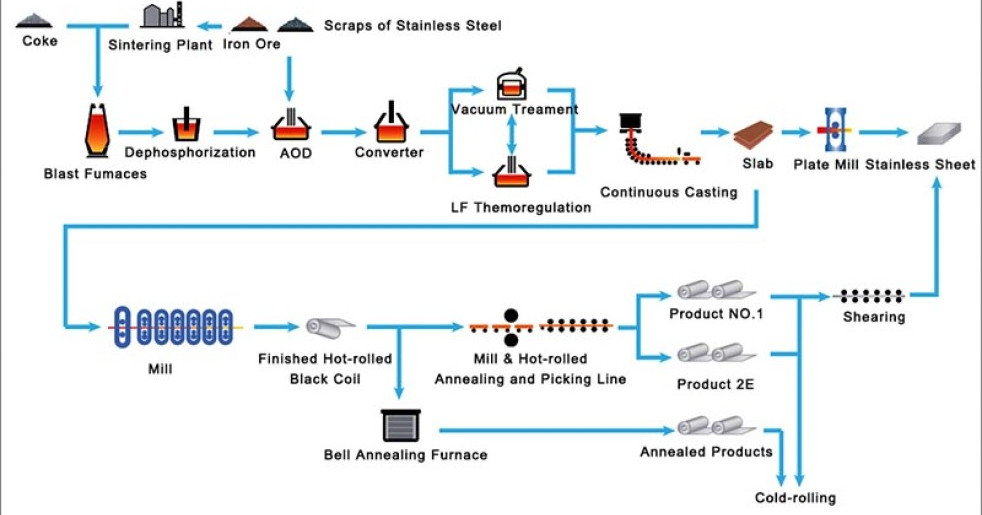

Stainless Steel Coil Manufacturing Process

Melting and refining: The first step in the process is to melt the raw materials in a furnace, typically using electric arc or induction heating. The molten steel is then refined to remove any impurities that may be present.

- Casting: Once the steel has been refined, it is cast into large slabs or billets, which can weigh several tons.

- Hot rolling: The slabs or billets are then heated and passed through a series of hot rolling mills, which reduce the thickness of the steel and shape it into coils.

- Annealing: After hot rolling, the coils are annealed, which involves heating the steel to a specific temperature and then cooling it slowly. This process helps to reduce any internal stresses that may have built up during hot rolling and improves the strength and ductility of the steel.

- Cold rolling: Once the steel has been annealed, it is passed through a series of cold rolling mills, which further reduce its thickness and improve its surface finish.

- Finishing: The coils are then subjected to various finishing processes, such as polishing or grinding, to achieve the desired surface finish.

- Cutting and packaging: Finally, the coils are cut to size and packaged for shipment to customers.

It's worth noting that there may be variations in the exact process used depending on the specific type of stainless steel being produced, as well as the equipment and techniques used by individual manufacturers.

How to Choose Stainless Steel Coils?

Choosing the right stainless steel coils depends on several factors, including the intended application, environment, and budget. Here are some steps to follow when selecting stainless steel coils:

- Determine the required properties: Consider the properties that are most important for the intended application. For example, if corrosion resistance is critical, you may need to select a grade of stainless steel that is highly resistant to corrosion.

- Determine the required thickness: The thickness of the stainless steel coil will depend on the application and the load it will need to bear. Thicker coils offer greater strength and durability, but may also be more expensive.

- Consider the surface finish: The surface finish of the stainless steel coil can impact its aesthetic appearance, as well as its resistance to corrosion and wear. Options include smooth, polished finishes and textured or brushed finishes.

- Consider the grade of stainless steel: Different grades of stainless steel offer different properties and performance characteristics. Consider factors such as corrosion resistance, strength, and weldability when selecting the appropriate grade.

- Consider the environment: The environment in which the stainless steel coil will be used can impact its performance and durability. Consider factors such as temperature, humidity, and exposure to corrosive substances when selecting the appropriate material.

- Consider the budget: Stainless steel coils can vary significantly in price depending on the grade, thickness, and surface finish. Consider your budget when selecting the appropriate material.

By considering these factors, you can select the appropriate stainless steel coils for your intended application, ensuring optimal performance, durability, and cost-effectiveness. It may also be helpful to consult with a stainless steel supplier or industry expert for guidance on selecting the appropriate material for your specific needs.

Conclusion

Thanks for taking the time to read this article. There is a wide selection of stainless steel coils and color-coated coils on the Bestsuppliers platform. You can get the cheapest coils for wholesale. Also, if you have any questions about stainless steel coils or color-coated coils, please contact us here, or you can leave your comment below.