building material manufacturers

Introduction

In the ever-evolving realm of construction, where creativity and precision intertwine to shape the world we inhabit, the choice of building materials and their manufacturers is a decision that resonates far beyond the confines of any blueprint. In this intricate dance of design and engineering, building material manufacturers emerge as the silent architects of our urban landscapes. Their role transcends mere supply; it is the embodiment of innovation, quality, and sustainability.

In the following exploration, we embark on a comprehensive journey through the fascinating world of building material manufacturers and their profound impact on the construction industry. From the selection of common and specialized materials to the importance of quality, the process of finding the right manufacturer, the sustainability imperative, customization, cost considerations, and logistics, we delve into each facet of this industry. Through real-life case studies and a glimpse into future trends, we unravel the pivotal role these manufacturers play in shaping the skylines of tomorrow. Join us as we uncover the intricate interplay between materials, manufacturers, and the architecture that defines our world.

Types of Building Material

Overview of Common Building Materials

In the grand orchestration of construction, common building materials form the fundamental notes that harmonize to craft the symphony of architectural excellence. Among these stalwarts, concrete reigns supreme, boasting a resolute blend of cement, aggregates, and water. Its prevalence in construction can be attributed to its versatility, durability, and malleability during application.

Simultaneously, steel, with its tensile strength and ductile nature, adds the skeletal framework to edifices, ensuring structural integrity. Wood, an age-old favorite, enchants with its organic warmth, ideal for interior design and residential construction. Brick, redolent of tradition, not only weaves history into walls but also exemplifies durability.

Beyond these staples, an array of composite materials such as fiber-reinforced polymers (FRP) and engineered wood products now grace the palette of builders, offering innovative solutions that augment structural performance and architectural aesthetics.

Specialized Building Materials for Unique Projects

In the domain of construction, not all projects are created equal. Specialized endeavors demand bespoke materials to transcend the boundaries of the ordinary. High-strength concrete infused with additives can withstand the rigors of skyscraper construction, while fiber cement boards clad sleek facades with weather-resistant élan.

Furthermore, geosynthetics, an unassuming category, finds itself indispensable in engineering projects. Geotextiles and geomembranes, for instance, underpin soil stabilization and environmental containment. Their subtle presence belies their significant role in safeguarding the environment and bolstering infrastructure.

Beyond earthly realms, the aerospace industry calls upon advanced materials like carbon composites and titanium alloys to fashion aircraft and spacecraft, where the union of strength and lightness is paramount.

The Role of Building Material Manufacturers in Construction

At the fulcrum of the construction ecosystem, building material manufacturers emerge as the architects of possibility. They craft the very substances that will either elevate or undermine the built environment. The selection of these manufacturers transcends mere commercial transactions; it represents an ideological choice that resonates throughout the life of the structure.

Manufacturers play a multifaceted role. They research, innovate, and produce materials that adhere to stringent quality standards. Simultaneously, they provide expertise and guidance, ensuring architects, engineers, and builders find the ideal material solutions to manifest their vision. These manufacturers are the custodians of technological advancement, as they continuously refine their offerings to align with evolving industry demands.

Why Choosing the Right Building Material Manufacturer Matters

In the labyrinthine maze of construction, the choice of a building material manufacturer reverberates through every phase of a project. The repercussions extend far beyond the initial procurement. Here's why it matters profoundly:

- Quality Assurance: Reputable manufacturers invest in research and development, assiduously honing the characteristics of their materials. This ensures that the materials procured are of the highest caliber, meeting or even surpassing industry benchmarks. This translates to heightened durability, structural reliability, and, ultimately, the longevity of the constructed edifice.

- Sustainability Prowess: As the world shifts towards sustainable building practices, the choice of manufacturer becomes pivotal. Ethical manufacturers are at the forefront of sustainability efforts, producing eco-friendly materials that reduce environmental impact. This not only fulfills regulatory requirements but also aligns with the contemporary ethos of responsible construction.

- Innovation & Customization: A dynamic manufacturer embraces innovation, continually introducing novel materials and construction methods. This fosters a fertile ground for architects and builders to experiment, pushing the boundaries of design. Moreover, manufacturers with the capacity for customization can tailor materials to specific project requirements, granting architects unparalleled creative latitude.

- Project Efficiency: Efficiency in construction is a vital facet of both budget adherence and project timelines. Manufacturers who offer reliable supply chains, timely deliveries, and technical support streamline the construction process. The ripple effect of this efficiency encompasses cost savings and the timely realization of the project's vision.

The Importance of Quality

Quality stands as the unyielding cornerstone in the construction industry, where the interplay of architectural vision and structural integrity reigns supreme. This chapter delves deep into the vital importance of quality in building materials and its profound impact on construction projects.

Quality Standards in Building Materials

Within the intricate tapestry of construction, quality standards are the threads that bind materials into the fabric of robust, enduring structures. A harmonious symphony of industry standards, regulations, and certifications ensures that building materials meet and often exceed stringent benchmarks.

Uncompromising materials undergo meticulous testing, subjected to arduous assessments that evaluate factors such as durability, structural resilience, and resistance to environmental stressors. These standards extend from the composition of concrete mixtures to the alloy composition of structural steel, ensuring that each component meets the rigors of the construction ecosystem.

Quality is not just a buzzword; it's a promise etched in concrete, an assurance that the materials procured are forged to withstand the test of time. Adherence to these standards is the first step in ensuring that the edifices that grace our cities stand as epitomes of both artistry and durability.

How Quality Affects Construction Projects

Quality in building materials is not a passive attribute; it's a dynamic force that influences every facet of a construction project. From the moment the first cornerstone is laid to the final finishing touches, the impact of quality reverberates through every phase.

- Structural Integrity: At the core of quality lies structural integrity. High-quality materials, from the steel reinforcement to the foundation concrete, guarantee the steadfastness of the structure. They fortify against structural vulnerabilities, ensuring that the building can endure the test of time and the forces of nature.

- Cost-Efficiency: Paradoxically, quality often leads to cost-efficiency in construction. Superior materials require less maintenance and repair over their lifecycle, reducing long-term operational costs. Moreover, they minimize downtime and unforeseen expenses, streamlining the construction process.

- Architectural Excellence: Quality materials enhance the aesthetic appeal of the structure. Their resilience allows architects to push the boundaries of design, creating visually stunning edifices that stand as testaments to human creativity.

- Sustainability: Quality is intrinsically linked to sustainability. Eco-friendly, high-quality materials reduce environmental impact, aligning with the global shift towards responsible construction practices.

Ultimately, quality in building materials is not an extravagance; it's an investment in the longevity, efficiency, and visual allure of construction projects. It is the lynchpin upon which the success of any architectural endeavor hinges.

Finding the Right Building Material Manufacturer

Choosing the right building material manufacturer is akin to selecting a partner for a long and challenging journey. This chapter navigates the terrain of research and evaluation, offering insights into the meticulous process of identifying manufacturers who embody the ideals of quality, sustainability, and innovation.

Researching and Evaluating Manufacturers

The quest for the right manufacturer commences with diligent research. Prospective manufacturers should be subjected to comprehensive evaluations that encompass a spectrum of criteria.

- Reputation: A manufacturer's reputation is a barometer of their trustworthiness. Investigate their history, track record, and past projects. A manufacturer with a proven legacy of delivering high-quality materials is often a dependable choice.

- Quality Standards: Scrutinize the manufacturer's adherence to quality standards and certifications. Verify if they comply with industry regulations and have a reputation for producing materials that meet or exceed these benchmarks.

- Innovation: The dynamism of the construction industry demands innovation. Assess the manufacturer's commitment to research and development, as this drives the introduction of cutting-edge materials and construction techniques.

- Sustainability: Ethical manufacturers prioritize sustainability. Scrutinize their ecological practices, including material sourcing, waste management, and energy efficiency.

- Financial Stability: A financially stable manufacturer is more likely to fulfill long-term commitments. Investigate their financial health and stability to ensure that they can support large-scale projects.

Getting Recommendations from Industry Experts

While research is invaluable, the wisdom of industry experts is an equally potent resource. Leverage their insights to refine your selection process.

- Architects and Engineers: Collaborate with architects and engineers who have firsthand experience with manufacturers. They can provide valuable recommendations based on their project successes.

- Peers and Colleagues: Networking with peers and colleagues in the construction industry can yield recommendations from those who have faced similar challenges in the past.

- Industry Associations: Industry associations often maintain directories of reputable manufacturers. These organizations can provide a curated list of manufacturers known for their quality and reliability.

Sustainability in Building Materials

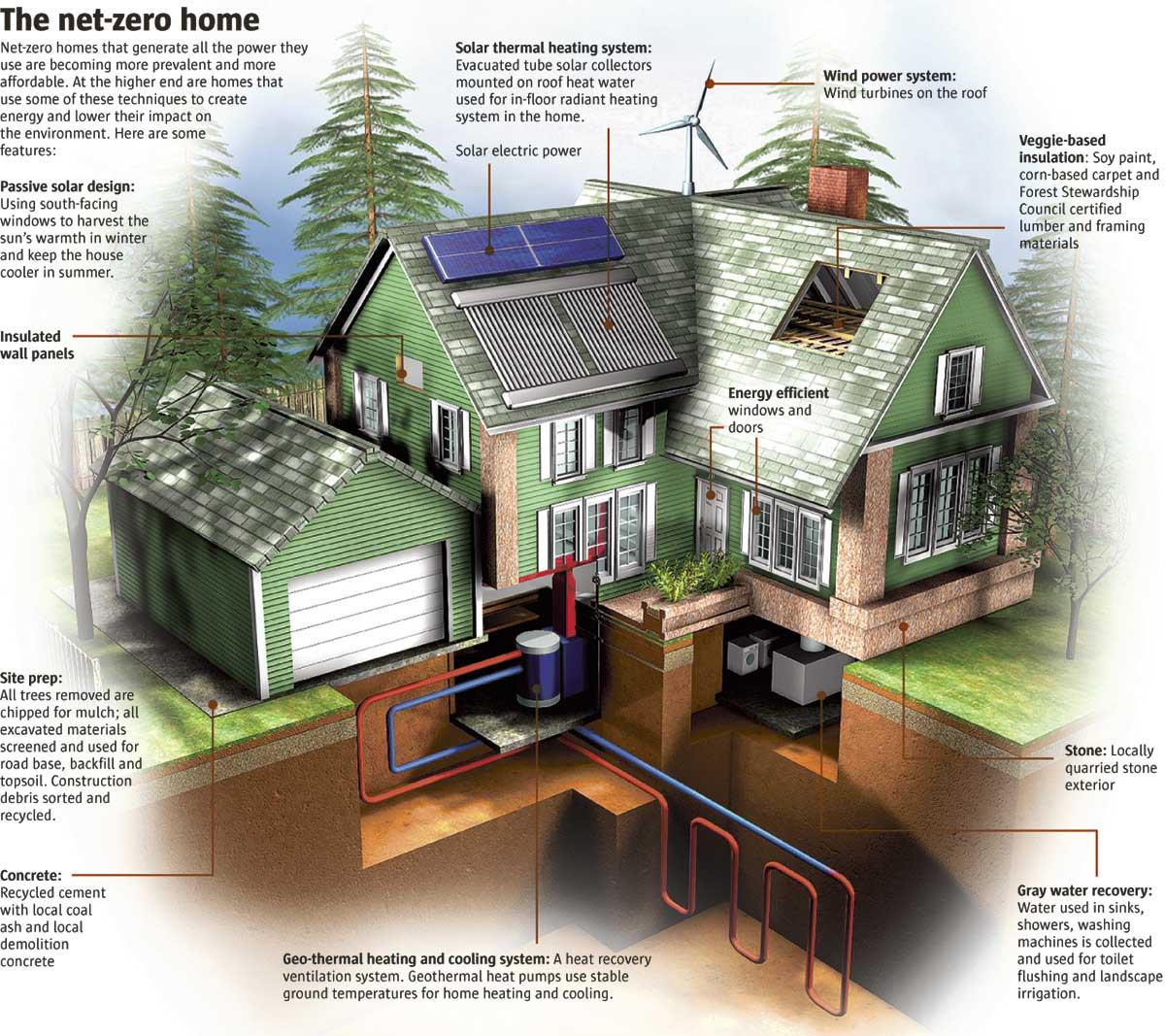

Sustainability in the realm of construction materials is not merely a trend; it's an imperative for a world grappling with environmental challenges. In this chapter, we delve into eco-friendly building material options and the myriad benefits they offer.

Eco-Friendly Building Material Options

Sustainability in building materials necessitates a departure from conventional practices, embracing alternatives that tread lightly on the planet. These options not only reduce environmental impact but also contribute to a healthier, more responsible construction industry.

- Bamboo: Often referred to as the "green steel" of the plant world, bamboo is a rapidly renewable resource. Its growth cycle is a fraction of traditional timber, making it an eco-friendly alternative for a wide range of applications, from flooring to structural elements.

- Recycled Materials: Incorporating recycled materials, such as reclaimed wood or recycled glass, not only reduces landfill waste but also conserves resources. These materials offer unique aesthetics while championing sustainability.

- Low VOC Paints and Finishes: Volatile Organic Compounds (VOCs) are harmful chemicals emitted by some paints and finishes. Low VOC options minimize indoor air pollution and contribute to healthier indoor environments.

- Green Insulation: Conventional insulation materials often pose environmental concerns. Green insulation alternatives like cellulose, made from recycled paper, or sheep's wool, offer effective thermal properties without harming the planet.

- Solar Tiles: Solar power integrated into building materials, such as solar tiles or shingles, harnesses renewable energy while seamlessly blending with the architectural design.

Benefits of Using Sustainable Building Materials

The adoption of sustainable building materials goes beyond environmental stewardship; it yields a multitude of benefits for both construction projects and the planet.

- Reduced Environmental Footprint: Sustainable materials reduce the depletion of natural resources, minimize waste, and lower energy consumption in production, significantly shrinking the carbon footprint of construction projects.

- Improved Indoor Air Quality: Low VOC materials enhance indoor air quality, promoting healthier living and working environments.

- Energy Efficiency: Sustainable materials often possess superior thermal properties, contributing to energy-efficient buildings with reduced heating and cooling costs.

- Enhanced Durability: Many sustainable materials, like bamboo and recycled metal, exhibit remarkable durability, translating to longer-lasting structures with reduced maintenance needs.

- Compliance with Regulations: Governments worldwide are increasingly imposing stringent environmental regulations. Using sustainable materials ensures compliance and future-proofs construction projects.

In embracing eco-friendly building materials, construction professionals not only champion a greener future but also reap tangible benefits that extend to the bottom line and the well-being of building occupants.

Customization and Design

The world of construction is as diverse as the architectural visions it brings to life. In this chapter, we explore the significance of tailoring building materials to project needs and the collaborative process with manufacturers to achieve custom designs.

Tailoring Building Materials to Project Needs

No two construction projects are alike, and as such, a one-size-fits-all approach to building materials often falls short. Tailoring materials to the specific needs of a project is a practice that yields superior results in both functionality and aesthetics.

- Structural Requirements: Different projects demand different structural characteristics. Whether it's load-bearing capabilities, flexibility, or resistance to specific environmental conditions, materials must align with the project's unique demands.

- Aesthetic Considerations: Architectural designs come to life through the choice of materials. Tailoring materials to the desired aesthetic, whether it's a sleek modern look or a rustic charm, ensures that the building's visual identity aligns with the design vision.

- Sustainability Goals: Projects with sustainability at their core require materials that meet specific eco-friendly criteria. Customizing materials to fulfill these goals involves selecting options with low environmental impact and high energy efficiency.

Collaborating with Manufacturers on Custom Designs

Achieving customization often involves a close collaboration between architects, engineers, and building material manufacturers. This partnership is instrumental in translating design concepts into tangible materials that meet project requirements.

- Initial Consultation: The process typically begins with an initial consultation between the project team and the manufacturer. During this phase, project goals, design specifications, and sustainability targets are discussed.

- Material Selection: Based on the project's requirements, the manufacturer provides recommendations for suitable materials. This includes options for eco-friendly materials, finishes, and other customizations.

- Prototype Development: Prototypes or samples may be developed to assess the materials' suitability and appearance. This phase allows for fine-tuning and adjustments before full-scale production.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the custom materials meet the specified standards.

- Delivery and Installation: Once the custom materials are manufactured, they are delivered to the construction site for installation. The manufacturer may provide on-site support to ensure proper installation.

Customization in building materials is not a luxury but a necessity in modern construction. It ensures that each project realizes its unique vision while meeting functional, aesthetic, and sustainability requirements. The collaborative effort between construction professionals and manufacturers is the conduit through which customization becomes reality, resulting in exceptional architectural outcomes.

Cost Considerations

In the intricate web of construction, where vision converges with practicality, navigating the delicate balance between quality and budget is an art form. Chapter 6 delves into the crucial considerations of managing costs while upholding quality in construction projects.

Balancing Quality and Budget

Achieving a harmonious equilibrium between quality and budget is often the linchpin of construction projects. Here, we explore the strategies and considerations that underpin this delicate balancing act.

- Value Engineering: Value engineering is the systematic approach of optimizing project value while minimizing costs. It involves scrutinizing every element of the project, from materials to design, to identify cost-saving opportunities without compromising quality.

- Life-Cycle Cost Analysis: Rather than solely focusing on upfront costs, construction professionals increasingly consider life-cycle costs. This comprehensive analysis takes into account not only the initial investment but also ongoing operational and maintenance expenses, ensuring that long-term savings are maximized.

- Cost-Benefit Analysis: Assessing the cost-benefit ratio of various materials and construction methods is a critical step. It involves weighing the initial investment against the expected benefits in terms of longevity, energy efficiency, and maintenance costs.

- Strategic Procurement: Leveraging the power of strategic procurement involves selecting the right suppliers and materials that align with the project's quality and budget goals. This may entail forming partnerships with manufacturers who offer competitive pricing without compromising on quality.

Negotiating Prices with Manufacturers

Effective negotiation with building material manufacturers is an art that can yield substantial cost savings for construction projects. This section explores negotiation strategies and considerations when dealing with manufacturers.

- Volume Discounts: Manufacturers often offer volume discounts for bulk orders. Negotiating favorable terms based on the quantity of materials required can result in significant cost reductions.

- Long-Term Contracts: Establishing long-term relationships with manufacturers can lead to more advantageous pricing arrangements. Manufacturers may be willing to provide favorable terms for repeat business.

- Price Comparison: Conducting thorough price comparisons among different manufacturers can uncover opportunities for negotiation. Knowing the market rates and being prepared to negotiate can yield favorable outcomes.

- Value-Added Services: Negotiating value-added services, such as free delivery or post-purchase support, can enhance the overall value proposition offered by manufacturers.

In conclusion, cost considerations in construction extend beyond mere budgeting. Achieving the right balance between quality and budget necessitates a strategic approach that incorporates value engineering, life-cycle analysis, and effective negotiation with manufacturers. This chapter underscores the significance of cost management as a pivotal aspect of successful construction projects.

Delivery and Logistics

In the complex world of construction, timely and efficient delivery of building materials is the lifeblood that keeps projects on schedule. Chapter 7 explores the intricacies of ensuring material delivery and managing logistics for large-scale projects.

Ensuring Timely and Efficient Material Delivery

Timely delivery of building materials is a cornerstone of construction project management. Delays in material delivery can lead to cascading setbacks and increased costs. Here, we delve into strategies for ensuring the punctual arrival of materials.

- Precise Scheduling: A meticulously crafted construction schedule should account for the precise timing of material deliveries. Coordinating the arrival of materials with the project's milestones ensures that they are on-site when needed.

- Communication with Suppliers: Maintaining open lines of communication with material suppliers is essential. Regular updates on project progress and any changes in material requirements allow suppliers to plan deliveries accordingly.

- Just-In-Time (JIT) Delivery: JIT delivery is a strategy that involves receiving materials exactly when they are needed in the construction process, minimizing the need for storage space, and reducing the risk of material damage or theft.

- Emergency Response Planning: Construction projects are not immune to unforeseen challenges. Having contingency plans in place for adverse weather, transportation disruptions, or supplier issues is essential to mitigate potential delays.

Managing Inventory for Large-Scale Projects

Large-scale construction projects often involve managing vast quantities of materials, requiring robust inventory management strategies. This section delves into the complexities of handling inventory efficiently.

- Inventory Tracking Systems: Implementing sophisticated inventory tracking systems, such as RFID (Radio-Frequency Identification) or barcoding, allows for real-time monitoring of materials. This streamlines inventory management and minimizes the risk of shortages or overstocking.

- Storage and Organization: Proper storage and organization of materials on-site are essential to prevent damage and loss. Categorizing materials, securing them from the elements, and ensuring they are easily accessible contribute to efficient management.

- Material Handling Equipment: Investing in the right material handling equipment, such as cranes, forklifts, or conveyor systems, can significantly streamline the movement of materials on large-scale construction sites.

- Sustainability in Logistics: Sustainable logistics practices, such as optimizing transportation routes and minimizing waste in material packaging, not only reduce environmental impact but also contribute to cost savings.

In the intricate dance of construction, the successful management of material delivery and logistics is akin to orchestrating a symphony. It requires meticulous planning, effective communication, and the utilization of modern technologies to ensure that materials arrive precisely when and where they are needed. By mastering these aspects, construction professionals can maintain project timelines, control costs, and ultimately realize the visions they set out to build.

Warranty and Support

In the intricate world of construction, where precision and planning reign supreme, understanding manufacturer warranties and post-purchase support mechanisms is paramount. This chapter explores the nuances of these critical aspects that ensure the longevity and reliability of construction projects.

Understanding Manufacturer Warranties

Manufacturer warranties are the bedrock of assurance in the construction industry. These contractual commitments, often overlooked but vital, define the terms under which materials are guaranteed. Here, we delve into the intricacies of manufacturer warranties.

- Coverage and Duration: The specifics of warranty coverage and its duration vary widely among manufacturers. Some warranties may cover materials for a limited time, while others extend for decades. Understanding the scope and duration of coverage is essential.

- Conditions and Limitations: Manufacturer warranties often come with conditions and limitations. These may include requirements for proper installation, maintenance, and usage. Deviating from these stipulations can void the warranty.

- Exclusions: Warranties typically exclude specific situations or damages. These exclusions can range from natural disasters to improper handling. Familiarizing oneself with these exclusions is crucial for informed decision-making.

- Transferability: Some warranties are transferable to subsequent property owners, while others are not. Knowing whether a warranty can be transferred can affect property resale value.

Post-Purchase Support and Maintenance

Beyond warranties, post-purchase support and maintenance are essential aspects of ensuring the continued performance and longevity of building materials. Here, we explore the importance of these services.

- Maintenance Guidelines: Manufacturers often provide maintenance guidelines for their materials. Adhering to these guidelines is crucial for preserving material integrity and performance over time.

- Technical Support: Access to technical support from manufacturers can be invaluable. This support may include assistance with installation, troubleshooting, or addressing unexpected issues.

- Repair and Replacement: In the event of material defects or damage, understanding the manufacturer's policies regarding repair or replacement is essential. Timely action can prevent minor issues from escalating.

- Sustainability Initiatives: Manufacturers increasingly offer sustainable practices and services, such as recycling programs for old materials or sustainable disposal options. These initiatives align with environmentally responsible construction practices.

Future Trends in Building Materials

In the dynamic world of construction, the future holds promises of innovation and transformation. Chapter 10 takes a glimpse into the crystal ball of construction, exploring cutting-edge innovations in building material technology and anticipated changes that are poised to reshape the industry.

Innovations in Building Material Technology

The evolution of building materials is a symphony of innovation, where science and creativity converge to redefine the possibilities of construction. In this section, we explore some of the most promising innovations in building material technology.

- Nanotechnology Marvels: Nanotechnology is ushering in a new era of materials with extraordinary properties. Nanomaterials, with their minuscule scale, exhibit remarkable strength, resilience, and insulation capabilities. From self-cleaning surfaces to ultra-lightweight yet sturdy materials, nanotechnology promises groundbreaking advancements in construction.

- Self-Healing Materials: Imagine a world where building materials can repair themselves. Self-healing materials are no longer the stuff of science fiction. These materials contain capsules of healing agents that are released when cracks or damage occur, autonomously repairing the structure.

- Carbon-Capture Concrete: As sustainability takes center stage, carbon-capture concrete has emerged as a game-changer. This innovative material not only reduces carbon emissions during production but also actively captures and stores carbon dioxide from the atmosphere over time.

- Transparent Wood: Blending the strength of wood with the transparency of glass, transparent wood is poised to revolutionize architectural design. It offers energy efficiency, aesthetics, and structural integrity while allowing natural light to permeate spaces.

- Biodegradable Materials: The shift toward eco-conscious construction has spurred the development of biodegradable building materials. These materials decompose naturally, reducing the environmental footprint of construction projects.

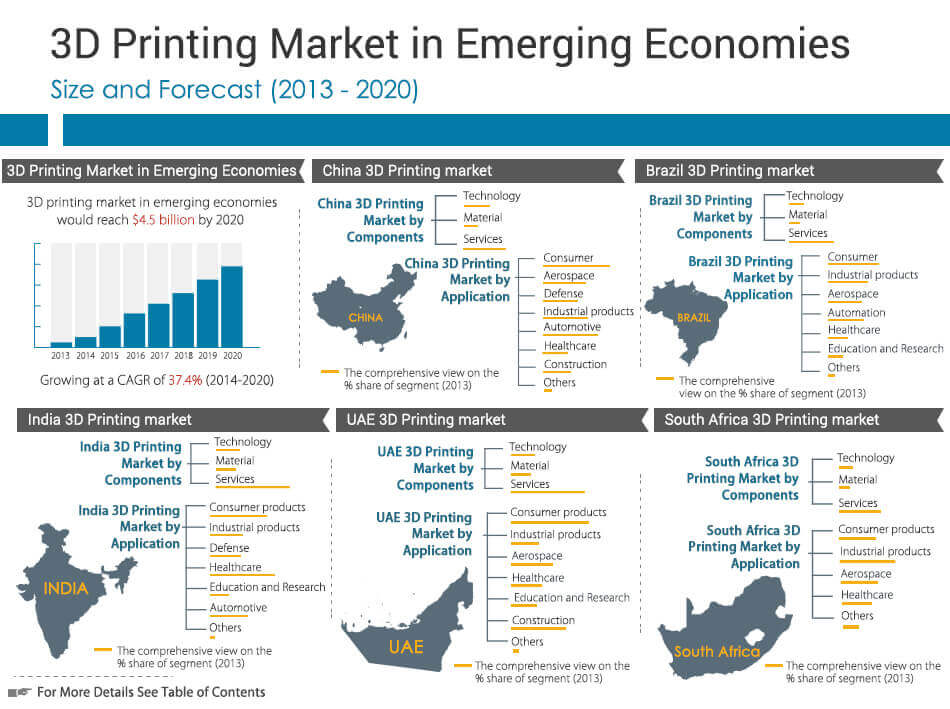

- 3D-Printed Structures: 3D printing technology is revolutionizing construction by enabling the rapid, cost-effective fabrication of complex architectural designs. Entire buildings can be 3D-printed with precision, saving time and resources.

Anticipated Changes in the Industry

The construction industry is on the cusp of transformative changes that will redefine the way we build. Anticipating these changes is essential for staying at the forefront of innovation.

- Prefab and Modular Construction: Prefabrication and modular construction methods are gaining momentum. These approaches, characterized by the assembly of pre-made building components off-site, offer speed, cost-efficiency, and reduced waste, revolutionizing construction practices.

- Sustainability Mandates: Sustainability is no longer a choice; it's a mandate. Anticipated changes include stricter regulations on eco-friendly construction practices, the integration of renewable energy sources, and the widespread adoption of green building certifications.

- Robotics and Automation: Robotics and automation are set to reshape construction sites. From bricklaying robots to autonomous heavy machinery, these technologies enhance precision, safety, and efficiency in construction.

- Data-Driven Design: The era of data-driven design is upon us. Advanced modeling, simulations, and data analytics enable architects and engineers to optimize designs for energy efficiency, structural integrity, and occupant comfort.

Conclusion

The choice of a building material manufacturer is not just about procurement; it's about laying the foundation for a project's success. It impacts structural integrity, sustainability, and innovation potential. The right choice echoes through the lifespan of the project, from inception to decades of use.

Key Takeaways for Successful Construction Projects

- Quality Matters: Quality materials are non-negotiable for structural integrity and longevity.

- Sustainability Is Essential: Embrace eco-friendly materials and practices for both ethical and cost-saving reasons.

- Customization Empowers: Tailored materials allow for the realization of unique visions.

- Cost Management Is Strategic: Balancing quality and budget is an art that requires strategic planning.

- Timeliness Is Key: Punctual material delivery and efficient logistics are indispensable for project success.

- Warranty and Support: Understanding manufacturer warranties and utilizing post-purchase support safeguards long-term performance.

- Innovation Is the Future: Staying ahead of the curve with innovative materials and construction practices is key to remaining competitive in the evolving industry.

These key takeaways serve as guiding principles for architects, engineers, and builders as they navigate the ever-evolving construction landscape. The choices made today reverberate through the structures they build, leaving a legacy of innovation, sustainability, and architectural brilliance.