How to manufacture a product

Introduction

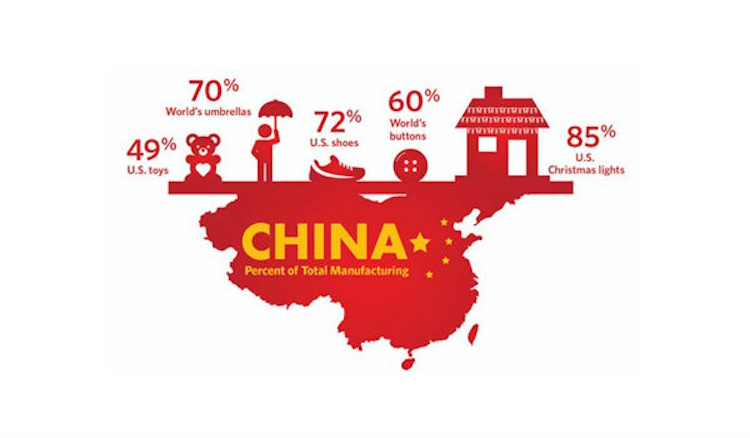

China is a powerful manufacturing country that attracts businesses from around the world due to its various capabilities and cost-effective solutions. In this article, we explore the manufacturing landscape in China and why it's a compelling choice for companies looking to improve production.

China is unquestionably significant in manufacturing. It has the largest population globally, strong infrastructure, and a well-developed industrial base. With its strategic location and large workforce, China is the world's primary manufacturing hub, serving various industries and production needs.

Why Choose China for Manufacturing

When considering manufacturing options, it's crucial to understand why China is a top choice. From cost savings to access to advanced technology, there are many reasons companies choose to establish operations in China. This article aims to clarify these factors to help you make an informed decision.

Understanding China's Manufacturing Landscape

Overview of China's Manufacturing Industry

China's manufacturing sector is dynamic, covering a wide range of industries, including electronics, textiles, automotive, aerospace, and more. To succeed in China, it's essential to grasp the details of this extensive industry. Chinese factories employ cutting-edge technology and skilled workers to ensure high production quality.

Key Manufacturing Sectors in China

China's manufacturing landscape is diverse, with several sectors contributing to its industrial strength. Prominent sectors include electronics, automotive, textiles and apparel, machinery, and pharmaceuticals. Each sector offers unique opportunities and challenges, so it's vital to align your business goals with the right sector. The electronics sector, for example, has a global supply chain and is pivotal in China's manufacturing landscape.

Benefits of Manufacturing in China

The decision to manufacture in China offers numerous advantages, with cost-effectiveness being a significant one. China's lower labor costs and economies of scale make it an attractive destination for companies seeking to reduce production expenses. Furthermore, China's extensive supplier network enhances cost efficiency. China's manufacturing ecosystem also boasts a robust infrastructure, enabling efficient logistics and transportation. Additionally, the government provides incentives and support to foreign businesses, creating a favorable business environment.

Setting Clear Objectives

Defining Your Product and Its Specifications

Before you start manufacturing in China, it's essential to carefully define your product and its specifications. Having a clear understanding of these details is crucial for successful production. Collaborating closely with a skilled design and engineering team can help you turn your vision into a tangible product.

Establishing Production Volume Requirements

Production volume needs can vary widely between industries. Whether you need small-batch production or high-volume manufacturing, China's manufacturing facilities can accommodate your requirements. Align your production volume strategically with market demand to optimize inventory management.

Budgeting and Cost Analysis

Conducting a thorough cost analysis is vital for successful manufacturing in China. In addition to labor expenses, consider factors like materials, logistics, and overhead costs. Developing a comprehensive budget that covers all aspects of production will enable you to make well-informed financial decisions.

Finding the Right Manufacturing Partner

Researching Chinese Manufacturers

In the global manufacturing landscape, China is a significant player, offering numerous opportunities for businesses worldwide. However, finding the right manufacturing partner in this vast and dynamic country can be challenging. To start this journey successfully, thorough research is your first step.

China's manufacturing industry is extensive and diverse, encompassing various regions and sectors. Begin your research by identifying the specific niche or industry your product belongs to. Utilize industry databases and trade publications to gain valuable insights into potential manufacturing partners. Additionally, consider attending trade shows and exhibitions in China to meet manufacturers in person and observe their capabilities firsthand.

Evaluating Supplier Credibility

In the complex world of Chinese manufacturing, supplier credibility is crucial. It can significantly impact the success of your venture. Begin by scrutinizing the credentials and certifications of potential partners. ISO certifications, for example, can indicate a manufacturer's commitment to quality.

Examine the manufacturer's track record by requesting references and contacting previous clients. Online platforms and forums dedicated to supplier reviews can also provide valuable feedback from peers. Assess the financial stability of the manufacturer, as it can affect their ability to consistently fulfill your orders.

Navigating Language and Cultural Barriers

Effective communication is essential for a successful manufacturing partnership, and in China, language and cultural differences can be significant challenges. Overcoming these obstacles requires careful planning and cultural sensitivity.

Consider hiring a local interpreter or a bilingual project manager who can bridge the language gap. Familiarize yourself with Chinese business customs and etiquette, which can differ significantly from Western practices. Building trust and fostering positive relationships are critical aspects of successfully navigating cultural differences.

Intellectual Property and Legal Considerations

Protecting Your Intellectual Property

Securing your intellectual property (IP) is a top priority when manufacturing in China due to the risk of IP theft and infringement. Take proactive steps to safeguard your innovations.

Begin by registering your trademarks, patents, and copyrights in China. Consult with legal experts knowledgeable about Chinese IP law for guidance. Implement strong security measures in your manufacturing facilities to protect sensitive designs and data. Confidentiality agreements with your Chinese partners can also provide added protection.

Complying with Chinese Regulations

Navigating the complex web of Chinese regulations is essential for foreign businesses. Compliance covers various aspects, from environmental standards to product safety rules, extending beyond IP laws.

Consult with legal experts familiar with Chinese regulations to ensure your products meet all applicable standards. Create a compliance checklist specific to your industry and stay updated on regulatory changes. Staying informed about legal requirements is crucial to avoid costly setbacks or legal disputes.

Drafting a Solid Manufacturing Agreement

A well-crafted manufacturing agreement is essential for a successful partnership in China. This legal document should cover all aspects of the partnership, including production volumes, quality standards, pricing, and timelines.

Engage legal professionals experienced in international business contracts to create a comprehensive agreement that safeguards your interests. Clearly define terms related to quality control, inspection processes, and dispute resolution mechanisms. Ensure the agreement addresses potential scenarios and contingencies to minimize risks and uncertainties.

Quality Assurance and Quality Control

In the realm of manufacturing, maintaining the highest quality standards is vital. Quality Assurance (QA) and Quality Control (QC) are crucial components of a successful production process.

Implementing Quality Standards

Quality Assurance starts with setting and implementing rigorous quality standards aligned with industry-specific regulations and international quality frameworks. These standards serve as benchmarks for product excellence and brand reputation.

Manufacturers use tools and methodologies like Statistical Process Control (SPC) and Total Quality Management (TQM) for real-time monitoring and analysis of production processes, enabling timely adjustments and quality improvements.

Conducting Factory Audits

Regular factory audits are essential to maintain the highest levels of quality. These audits involve thorough inspections of manufacturing facilities and processes to identify areas for improvement and ensure compliance with quality standards.

Factory audits cover various aspects, including equipment calibration, employee training, and compliance with environmental and safety regulations. These assessments are often conducted by third-party auditing agencies or in-house QA teams to ensure objectivity and transparency.

Ensuring Product Consistency

Consistency in product quality is a hallmark of successful manufacturing. Quality Control teams play a crucial role by conducting inspections and tests throughout the production process.

This includes inspecting raw materials, monitoring production stages, and conducting final product inspections. Advanced technologies like Computer Vision and Artificial Intelligence are increasingly used for real-time quality assessment, ensuring products meet predetermined specifications.

Logistics and Supply Chain Management

Efficient logistics and supply chain management are crucial for the smooth movement of goods from production to consumers in today's globalized world.

Planning for Shipping and Transportation

The logistics process starts with careful planning for shipping and transportation. This involves selecting the appropriate mode of transportation, such as sea freight, air freight, or land transportation, based on factors like cost, urgency, and the nature of the goods.

Advanced logistics software and tools help optimize routes, ensuring on-time deliveries and cost savings. Implementing Just-In-Time (JIT) inventory management reduces excess inventory and lowers storage costs.

Customs and Import/Export Regulations

Navigating customs and import/export regulations is a vital part of global manufacturing, requiring a thorough understanding of international trade laws.

To streamline customs clearance, many manufacturers work with customs brokers who specialize in handling import and export documentation. Modern customs clearance software can expedite the process while ensuring compliance with legal requirements.

Efficient Supply Chain Strategies

Efficiency in the supply chain goes beyond transportation. Efficient supply chain strategies involve optimizing inventory management, demand forecasting, and supplier relationships.

JIT inventory management reduces costs, while demand forecasting tools use historical data and market trends to accurately predict future demand. Collaborative relationships with suppliers can lead to shorter lead times and reduced costs, benefiting both parties.

Cost Management and Pricing

In the complex world of manufacturing, cost management and pricing strategies are essential for success.

Managing Production Costs

Effective cost management starts with the core of manufacturing, encompassing factors like raw material procurement and production facility operation. Various methods are used to optimize production costs.

Value Engineering enhances product functionality while reducing production expenses. Lean Manufacturing principles minimize waste and optimize workflows, reducing costs. JIT inventory management prevents overstocking, lowering carrying costs.

Competitive Pricing

Setting competitive prices is a delicate balance that considers production costs, market demand, and competition. Manufacturers must analyze these factors to determine a pricing strategy that maximizes profitability without alienating customers.

Pricing models like Cost-Plus Pricing, Market-Oriented Pricing, and Penetration Pricing are available, each with its advantages and disadvantages. Regularly reviewing your pricing strategy is essential to stay competitive in a dynamic market.

Negotiating Favorable Terms

Negotiating favorable terms with suppliers and customers is a crucial aspect of cost management. Effective negotiation can lead to reduced procurement costs, extended payment terms, and advantageous credit agreements.

In supplier negotiations, forming long-term partnerships can yield better terms, including bulk purchase discounts and access to exclusive resources. Understanding customer needs and providing tailored solutions can justify premium pricing, ensuring a mutually beneficial partnership.

Production Process and Timelines

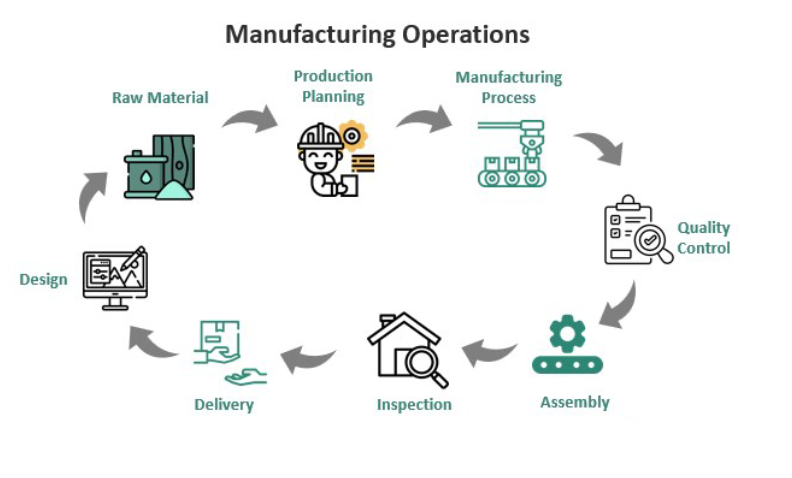

Understanding the Manufacturing Process

The manufacturing process consists of multiple stages, each contributing to the final product's quality and efficiency. Familiarizing yourself with these stages is crucial for effective project management.

From design and prototyping to material sourcing, assembly, and quality control, each step requires meticulous attention. Using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software can streamline design and production, ensuring precision and efficiency.

Creating a Production Timeline

Developing a production timeline is similar to coordinating a symphony, requiring detailed planning, coordination, and resource allocation. Manufacturers use project management tools and methods to ensure smooth production.

Tools like Gantt charts, Critical Path Analysis (CPA), and Program Evaluation and Review Technique (PERT) aid in task allocation, identifying dependencies, and estimating completion times. Realistic timelines are crucial for meeting customer demands and avoiding costly delays.

Dealing with Delays and Challenges

Despite careful planning, manufacturing projects often face unforeseen challenges and delays. Effectively managing these setbacks is a hallmark of successful project management.

Risk mitigation strategies, such as identifying potential bottlenecks and creating contingency plans, help navigate unexpected challenges. Embracing Industry 4.0 technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) enables predictive maintenance, reducing downtime due to equipment failures.

Cultural Etiquette and Communication

Understanding and respecting cultural norms are essential in the global manufacturing arena. Effective communication and cultural sensitivity lay the foundation for successful business relationships.

Building Strong Relationships

Strong relationships are essential for successful international manufacturing partnerships. Building trust and rapport with overseas counterparts leads to smoother collaborations and mutually beneficial outcomes.

Establishing a personal connection often starts with understanding and respecting cultural nuances. For example, in some cultures, business discussions may begin with social interactions and pleasantries before getting to the main topic. Learning about the customs and traditions of international partners demonstrates respect and sincerity.

Effective Communication Tips

Clear and concise communication is crucial when working with international manufacturing partners and transcending language barriers. Using plain language, avoiding idiomatic expressions, and confirming understanding can bridge linguistic divides.

Utilizing communication tools like video conferencing and translation software facilitates real-time interactions. Encouraging open dialogue and being receptive to feedback fosters a collaborative atmosphere where ideas and concerns can be freely exchanged.

Resolving Cultural Misunderstandings

Cultural misunderstandings are common in global business. Addressing these issues with patience and diplomacy is vital for maintaining productive relationships.

When faced with cultural misunderstandings, acknowledge the problem without blame, seek clarification, and offer explanations when necessary. Building cultural competency within your team through training and intercultural workshops can preempt potential conflicts and misunderstandings.

Quality Control and Post-Production

Once your manufacturing process is underway, maintaining uncompromised quality is crucial. Quality control and post-production support are essential for delivering excellence to customers.

Inspecting Finished Products

Quality control begins with a thorough inspection of finished products. Implementing strict quality standards and using specialized tools and methods are vital.

Utilize advanced quality control techniques such as Six Sigma and Total Quality Management (TQM) to ensure consistent product quality. Methods like random sampling, destructive testing, and non-destructive testing help identify defects and ensure compliance with specifications.

Handling Defects and Returns

Despite rigorous quality control, defects may occur. A robust system for managing defects and returns is essential.

Establish clear procedures for customers to report defects and ensure prompt responses and resolutions. Analyze the root causes of defects to implement preventive measures, reducing the chances of recurrence. A responsive customer service team capable of addressing concerns swiftly contributes to customer satisfaction and loyalty.

Post-Production Support and Warranty

Providing post-production support and warranties demonstrates your commitment to customer satisfaction. Offering warranties not only builds customer confidence but also legally obligates you to maintain product quality.

Communicate warranty terms and conditions to customers, and ensure your post-production support team is well-prepared to handle inquiries and issues. Efficient and timely warranty service can enhance your reputation and distinguish you in the global manufacturing market.

Scaling Your Manufacturing Operation

As your manufacturing business grows, scaling becomes crucial to meet higher demand and explore new growth opportunities. This section outlines key strategies for successful scaling.

Expanding Production Capacity

Expanding production capacity is the first step in scaling. This means investing in more machinery, workers, and infrastructure to handle increased production. Conduct a feasibility study to find the most cost-effective approach.

Modern technologies like automation and robotics can boost capacity while maintaining precision. Optimizing the production floor layout can streamline workflows and reduce bottlenecks.

Diversifying Product Lines

Diversifying your product offerings is a potent scaling strategy. It opens new markets and reduces reliance on one product or market, reducing risks and increasing revenue streams.

Conduct market research to find new product opportunities that match your capabilities. Understanding customer preferences, industry trends, and competition is crucial. Collaborate with product development experts to smoothly integrate new products.

Long-Term Growth Strategies

Sustainable growth goes beyond immediate scaling efforts. It involves diversifying customers, fostering innovation, and building a robust supply chain.

Diversify customers by exploring new markets or industries. Invest in Research and Development (R&D) for innovation and product improvement. Maintain an agile, reliable supply chain to meet growing demand and minimize disruptions.

Conclusion

Manufacturing in China requires careful planning and understanding of the local business culture and regulations. Cultivate strong relationships with reliable suppliers and stay updated on Chinese regulations. Adopt sustainable practices to enhance your reputation in the Chinese market.

Key Takeaways and Actionable Steps

- Scaling your manufacturing operation demands careful planning.

- Expand production capacity efficiently with automation and optimized workflows.

- Diversify product lines strategically through research and collaboration.

- Ensure long-term growth with customer diversification, innovation, and a reliable supply chain.

Implement these strategies to confidently scale your manufacturing operation and achieve success in the global marketplace.