Original Design Manufacturer ODM

Introduction

In the constantly changing manufacturing industry, the term "Original Design Manufacturer" or ODM is very important. This article explores ODMs, helping you understand their role, significance, and how they influence product development.

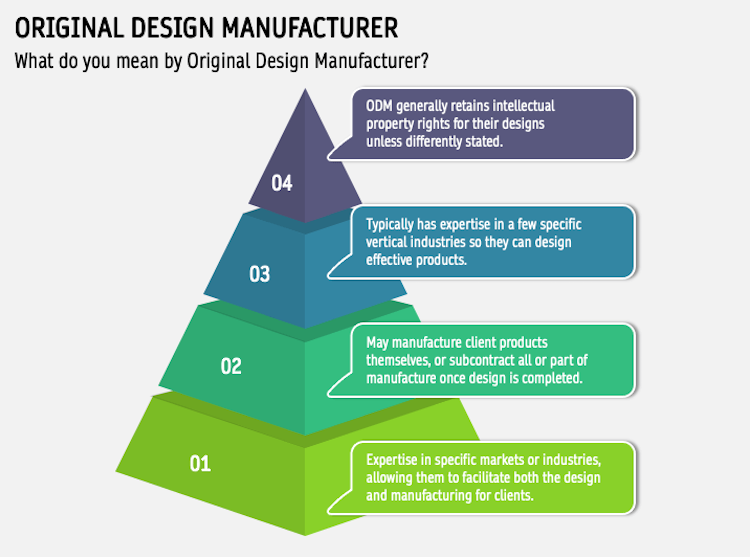

At its core, an Original Design Manufacturer, often called an ODM, is a company that designs and makes products, usually to be sold under another company's brand. ODMs are the hidden heroes of product development, creating items that carry a different company's logo.

Importance of ODM in the Manufacturing Industry

The importance of ODMs in today's manufacturing world cannot be overstated. They are a crucial part of the supply chain, driving innovation, reducing costs, and allowing companies to focus on what they do best.

Overview of What the Blog Post Will Cover

In the following sections, we'll explore the many roles of ODMs in product development. We'll discuss collaborative design efforts, cost-effectiveness, and their contributions.

The Role of ODM in Product Development

In today's competitive business world, the collaboration between companies and Original Design Manufacturers (ODMs) is vital in shaping product development. ODMs, often unsung heroes in manufacturing, bring valuable expertise, transforming how businesses create and market their products. In this article, we'll dive into the various roles ODMs play in product development. We'll explore how they assist in collaborative product design, the benefits of such partnerships, and their contributions to refining product ideas.

1. Collaborative Product Design

Successful product development with ODMs hinges on collaboration. These creative experts work closely with businesses to turn innovative ideas into real, market-ready products. With their deep knowledge of design and manufacturing, ODMs ensure that ideas become reality.

By working together, businesses and ODMs can create products that push the boundaries of innovation. This collaboration enables the integration of advanced features, cutting-edge technology, and ergonomic designs that might be challenging to achieve on their own.

Benefits of Collaborating with ODMs

Collaborating with ODMs offers more than just putting product ideas into action. These partnerships provide access to a wealth of knowledge and experience. ODMs bring a fresh perspective, helping businesses find new ways to improve their products.

Furthermore, ODMs are experts in optimization. They examine every aspect of a product, from materials to manufacturing processes, to make it more efficient and functional. This thorough approach often results in the creation of better products that excel in the market.

How ODMs Help Improve Product Ideas

Improvement is an art, and ODMs are masters of it. They take initial concepts and subject them to a rigorous analysis and enhancement process. By actively seeking feedback and continually improving product designs, ODMs turn good ideas into great ones.

The refinement process also includes rigorous testing and quality assurance, ensuring that the final product meets the highest performance and durability standards. ODMs excel at turning abstract ideas into concrete, high-quality products ready for the market.

2. Customization and Branding

Collaborating with ODMs offers the ability to customize products to align seamlessly with a brand's identity and needs. ODMs understand that a product represents more than just a physical item; it embodies a brand's values and principles.

ODMs work closely with companies to incorporate unique elements that define the brand, whether it's materials, color schemes, or design aesthetics. ODMs ensure that each product tells a compelling brand story.

Tailoring Products to Specific Brand Requirements

ODMs are adaptable experts who can align their production processes with the precise needs of their client's brands. This level of customization ensures that every product feels like a natural extension of the brand.

From visual elements like logos and packaging to functional aspects that resonate with a brand's target audience, ODMs make sure each product seamlessly integrates into the brand's ecosystem. This attention to detail helps businesses maintain a consistent and compelling brand image.

Maintaining Brand Identity Through ODM Partnerships

While ODMs bring their technical expertise, they do so while respecting the brand's identity. The result is a harmonious blend of innovation and brand continuity. Products developed in collaboration with ODMs not only meet high-quality standards but also uphold the unique essence of the brand.

3. Cost-Efficiency in Product Development

Financial considerations are crucial in any product development endeavor. ODMs excel in this area by providing a compelling solution to reduce costs without sacrificing quality.

How ODMs Help Reduce Development Costs

By leveraging economies of scale, ODMs can significantly cut production costs. Their established supply chains, production facilities, and streamlined processes lead to cost savings, benefiting companies seeking a higher return on investment.

Cost Comparison: In-House vs. ODM Product Development

To illustrate the economic advantages of ODM collaborations, it's essential to conduct a thorough cost comparison between in-house and ODM-driven product development. This analysis clarifies how ODMs enable businesses to achieve cost-efficiency, demonstrating that ODMs are not just partners but also strategic assets in pursuing innovation and growth.

Choosing the Right ODM Partner: A Strategic Guide

In the complex world of product development, selecting the correct Original Design Manufacturer (ODM) partner is a vital decision that can significantly influence your business's success. An ODM can assist in turning your ideas into reality, but picking the ideal match requires careful thought. In this article, we will explore the steps for selecting the right ODM partner and explain why each step is important.

1. Research and Due Diligence

Before entering into a partnership, thorough research and due diligence are essential. Begin by understanding your business needs and objectives. What do you want to achieve through this collaboration? What are your goals and timelines for product development?

The Significance of Market Research

Market research is equally crucial. Analyze market trends, consumer preferences, and your competitors. Identify gaps in the market that your product can fill. A deep understanding of the market landscape will guide your selection process.

Evaluating Potential ODM Partners

Once you have a clear understanding of your needs and the market, it's time to evaluate potential ODM partners. Consider factors like their industry reputation, track record, and experience in your specific niche.

2. Assessing Manufacturing Capabilities

An ODM's manufacturing capabilities are central to the partnership. Examine their production facilities, technology, and processes. Do they have the machinery and expertise required to bring your product to life?

Capacity, Technology, and Quality Assurance

Capacity is important. Ensure that the ODM can meet your production requirements. Evaluate their technological capabilities, as advanced machinery often leads to higher product quality. Confirm their quality assurance procedures and certifications to ensure consistent excellence.

The Role of Certifications and Compliance

Certifications and compliance are non-negotiable. Verify that the ODM complies with industry standards and regulatory requirements. This step guarantees the safety and integrity of your product.

3. Compatibility and Communication

Compatibility between your company and the ODM is crucial. Assess their corporate culture, values, and mission. Shared vision and values can promote a harmonious partnership.

Aligning Goals and Communication

Clear communication is essential for aligning goals and expectations. Define the scope, timelines, and milestones of your project. Discuss roles and responsibilities to prevent misunderstandings in the future.

Effective Communication with ODMs

Effective communication is a two-way process. Establish open channels for dialogue. Regular updates, meetings, and progress reports ensure that everyone remains on the same page.

Building a Strong Working Relationship

Building a strong working relationship requires time and effort. Invest in trust and mutual respect. Address challenges promptly and collaboratively. A strong partnership can lead not only to successful projects but also to long-term collaborations.

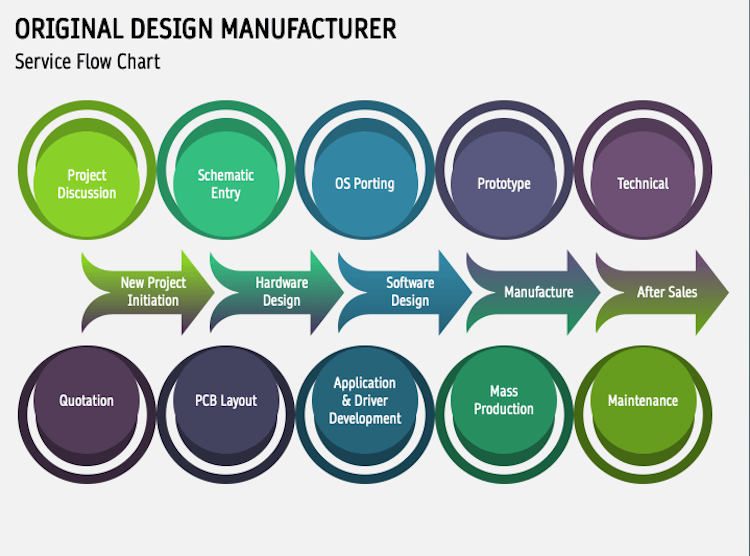

The ODM Process: From Idea to Production

In the complex world of manufacturing, the Original Design Manufacturer (ODM) process is where raw ideas and concepts turn into real, market-ready products. This article explores the stages of the ODM process, from the initial idea to the thorough production and quality control steps that ensure the final product not only meets but exceeds expectations.

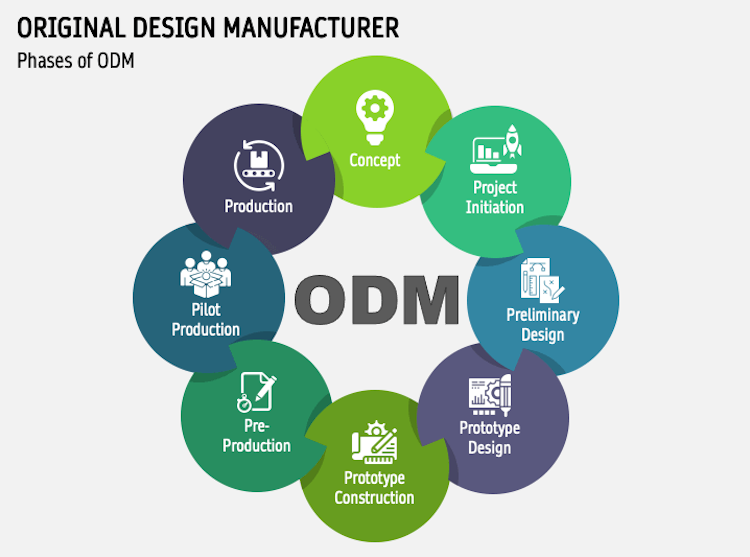

1. Initial Design and Idea Formation

The journey starts with a small idea, a spark of innovation. This is where the foundation for a new product is established. It's a stage of envisioning what the product will be, what issue it will solve, and how it will appeal to the target market.

Generating Ideas

Ideas are developed through brainstorming and creative thinking sessions. Multiple concepts are explored, and creativity flows freely. The aim is to refine the initial idea, identify potential challenges, and imagine the product's features and functions.

Creating Detailed Product Specifications

Once the concept is refined, it's time to create comprehensive product specifications. This document serves as the blueprint for the entire ODM process. It outlines materials, dimensions, features, and any specific requirements.

2. Prototyping and Sample Development

With detailed specifications, the next step involves creating prototypes and samples. This phase is where the theoretical idea becomes tangible, as prototypes give physical form to the product concept.

Prototyping Phase

Prototyping entails carefully developing a preliminary product model. It's a crucial step that allows for practical testing, identification of design issues, and refinement of functionality. The prototype serves as tangible proof of the concept.

Enhancing the Product through Sampling

Sampling takes the prototype further by creating multiple iterations. This iterative process allows for fine-tuning of design elements, materials, and functionality. Each sample is closely examined and improved until perfection is achieved.

3. Manufacturing and Production

Once the prototype and samples meet the desired standards, it's time to transition to full-scale manufacturing. This phase involves producing a larger quantity of units, moving from development to mass production.

Mass Production and Scaling Up

Mass production is a meticulous process that involves optimizing manufacturing procedures, establishing production lines, and ensuring the ability to produce at a larger scale. Efficiency, consistency, and volume are the primary focuses in this phase.

Quality Control and Assurance in ODM Manufacturing

Quality control is a constant aspect of the ODM process, but it is particularly important during mass production. Thorough testing, inspections, and adherence to quality standards are essential. Every product leaving the production line must meet strict criteria for performance, durability, and safety.

Benefits and Drawbacks of Using ODM Services

In the continually changing field of product development and manufacturing, companies often face the decision of whether to engage in Original Design Manufacturer (ODM) partnerships. These collaborations offer a range of advantages and potential challenges. In this article, we explore the benefits and drawbacks of using ODM services.

1. Advantages of ODM Partnerships

Cost Savings

One of the primary benefits of entering into an ODM partnership is cost savings. ODMs typically operate at a large scale, which allows them to spread fixed costs over a larger production volume. This results in reduced manufacturing expenses for businesses. Additionally, ODMs often have established supply chains, further streamlining costs.

Speed to Market

Speed is crucial in today's fast-paced business world. ODMs are well-equipped to expedite the product development cycle. Their expertise in design, prototyping, and manufacturing accelerates the time it takes to bring a product to market. This agility can be a game-changer, especially in industries where consumer preferences change rapidly.

Access to Expertise and Technology

Collaborating with ODMs provides businesses with access to a wealth of expertise and cutting-edge technology. ODMs specialize in various industries and have a deep understanding of market trends and consumer demands. They often invest in the latest machinery and production techniques, ensuring that products are manufactured with precision and innovation.

2. Potential Challenges and Drawbacks

Limited Control Over the Manufacturing Process

While ODM partnerships offer numerous benefits, they can entail relinquishing some control over the manufacturing process. Businesses may find themselves with limited influence over production decisions, which can be a concern when specific design or quality requirements are crucial.

Confidentiality and Intellectual Property Concerns

The sharing of intellectual property and product designs with ODMs can raise concerns about confidentiality. Protecting proprietary information becomes paramount. Businesses must establish robust contractual agreements and safeguards to ensure the security of their intellectual property throughout the partnership.

Future Trends in ODM Services

The landscape of Original Design Manufacturer (ODM) services is in constant evolution, driven by technological advancements, changing consumer preferences, and global market dynamics. In this article, we explore the future trends shaping the ODM industry, including the impact of technology, the growing importance of sustainability, and the exploration of emerging markets.

1. The Impact of Technology Advancements

As technology continues to advance rapidly, the ODM industry is also undergoing transformation. Cutting-edge technologies like artificial intelligence (AI), the Internet of Things (IoT), and 3D printing are revolutionizing product development and manufacturing. These innovations enhance efficiency, reduce costs, and enable more customized product offerings.

Industry 4.0 and Smart Manufacturing

The concept of Industry 4.0, which integrates digital technologies into manufacturing, is reshaping the ODM landscape. Smart manufacturing systems, with real-time data analytics, automation, and machine learning, are becoming standard. ODMs adopting Industry 4.0 principles offer more agile and responsive production processes.

Customization through Digitalization

Digitalization empowers ODMs to efficiently offer highly customized products. Advanced software and design tools allow for intricate product personalization, catering to individual consumer preferences. This trend fosters customer loyalty and minimizes excess inventory.

2. Sustainability and Eco-Friendly Manufacturing

Sustainability is a defining feature of the future ODM industry as consumers increasingly prioritize eco-friendly products. ODMs are responding by adopting sustainable manufacturing practices and using renewable materials.

ODMs' Role in Sustainable Practices

ODMs play a pivotal role in promoting sustainable practices across industries. They invest in clean energy sources, optimize production processes to reduce waste, and explore eco-friendly packaging options. Collaborations with ODMs promise a reduced carbon footprint.

Meeting Consumer Demand for Green Products

Consumers align their purchasing decisions with environmental values, driving demand for greener products. ODMs are at the forefront, developing eco-conscious, high-quality products that cater to this growing market segment focused on sustainable living.

3. ODMs in Emerging Markets

Emerging markets hold significant potential, and ODMs are actively exploring opportunities in new geographies. These markets offer untapped potential and diversification of product portfolios. ODMs adapt to local preferences and regulations in their pursuit of growth.

Exploring Opportunities in New Geographies

Entering new geographies presents challenges and opportunities. ODMs must navigate cultural nuances, trade regulations, and market dynamics. However, the potential for growth and market penetration is significant, making the exploration of emerging markets a strategic move for many ODMs.

Conclusion

Throughout this article, we embarked on a journey to explore the intricate world of Original Design Manufacturer (ODM) services and the transformative trends shaping the future of this industry. From technological advancements to sustainable practices and global expansion, ODMs stand at the forefront of modern manufacturing, driving innovation and change.

Recap of Key Points Discussed

- Technology Advancements: We witnessed how technology, including AI, IoT, and 3D printing, is revolutionizing ODM services, making them more efficient and adaptable.

- Smart Manufacturing: Industry 4.0 and smart manufacturing principles are reshaping ODM operations, enhancing agility and responsiveness.

- Customization through Digitalization: The digital era empowers ODMs to offer highly personalized products, catering to individual preferences.

- Sustainability: The growing demand for eco-friendly products influences ODMs to adopt sustainable manufacturing practices and renewable materials.

- ODMs' Role in Sustainability: ODMs actively contribute to sustainable practices by investing in clean energy, waste reduction, and eco-conscious packaging.

- Consumer Demand for Green Products: ODMs meet the rising consumer demand for environmentally friendly products, creating a more sustainable future.

- Exploring Emerging Markets: ODMs expand into emerging markets, diversifying their portfolios and adapting to local preferences.

- Opportunities in New Geographies: Despite challenges, the allure of new geographies presents significant growth opportunities for ODMs.

Final Thoughts on the Significance of ODM in Modern Manufacturing

In the grand scheme of modern manufacturing, ODMs have emerged as indispensable catalysts of innovation and efficiency. They bridge the gap between ideas and market-ready products, offering cost-effective, speedy, and customizable solutions. ODMs not only respond to consumer demands but also proactively shape the industry by adopting sustainable practices and embracing technological advancements.

Encouragement for Businesses to Consider ODM Partnerships

To businesses navigating the complex terrain of product development and manufacturing, the message is clear: consider ODM partnerships. The benefits are manifold, from cost savings and speed to market to access to expertise and technology. ODMs are not just service providers; they are strategic allies that can elevate your business's competitive edge.

As the manufacturing landscape continues to evolve, ODMs are at the forefront, shaping the products of tomorrow. Embracing ODM partnerships is not just a strategy; it's imperative for businesses aiming to thrive in an ever-changing world. The future of manufacturing is being written today, and ODMs hold the pen.