All You Need to Know About Screw Nails: The Versatile Hardware Fasteners

INTRODUCTION

Screw nails, also known as spiral nails or helical nails, are essential hardware fasteners widely used in construction, woodworking, and other industries. Combining the benefits of screws and nails, they provide superior holding power and versatility for a multitude of applications. In this blog post, we will explore the various types of screw nails, their uses, and the advantages they offer over traditional fastening options.

I. What are the Types of Screws Nails?

Screw nails come in various types, each designed to cater to specific needs and applications. Understanding the different types of screw nails will help you choose the most suitable option for your project. Let's take a closer look at each type:

A. Ring Shank Screw Nails:

Ring shank screw nails feature a helical shank with annular rings along its length. These rings provide exceptional grip and resistance against withdrawal forces. When driven into the material, the rings create a tighter hold, preventing the nail from easily backing out. This makes ring shank screw nails ideal for applications that require strong and secure fastening. They are commonly used in tasks such as framing, decking, and sheathing, where the material needs to be securely attached for structural stability.

B. Spiral Shank Screw Nails:

Spiral shank screw nails have a unique twisted or spiral-shaped shank. This design offers increased holding power and prevents pull-out. The spiraling shank creates a tighter grip within the material, reducing the chances of the nail becoming loose over time. Spiral shank screw nails excel in softer materials such as plywood, particleboard, and drywall. Their enhanced holding power makes them suitable for attaching metal brackets and hangers, providing a reliable and secure connection.

C. Smooth Shank Screw Nails:

Smooth shank screw nails, as the name suggests, have a straight, smooth shank without any ridges or rings. This design allows for easier insertion into the material, reducing the likelihood of splitting or damaging the surface. Smooth shank screw nails are often preferred for finish work, trim, and cabinetry, where aesthetics and minimizing surface damage are important considerations. Their smooth shank design makes it easier to drive into the material without causing unnecessary disruptions or surface imperfections.

By understanding the characteristics and specific uses of each type of screw nail, you can make informed decisions about which one is most appropriate for your project. Consider factors such as the material you're working with, the level of holding power required, and any concerns about surface damage or splitting. Choosing the right type of screw nail will ensure a secure and reliable fastening solution that meets your specific needs.

II. What are the Advantages of Screw Nails?

Screw nails offer several advantages over traditional nails, making them a preferred choice for many professionals and DIY enthusiasts. Let's explore the benefits of using screw nails in more detail:

A. Increased Holding Power:

One of the significant advantages of screw nails is their superior holding power. Unlike traditional nails, screw nails have threaded shanks that create a tighter grip when driven into the material. The threads effectively lock into the wood or other materials, providing enhanced resistance to pull-out and minimizing the risk of the nail becoming loose over time. This increased holding power ensures a more secure and reliable connection, making screw nails suitable for applications that require long-term stability and strength.

B. Easy Installation:

Installing screw nails is a straightforward process that can be easily accomplished with common tools such as a standard hammer or a power drill. The threaded design allows for smooth insertion into the material, while the sharp point of the nail helps to penetrate the surface with ease. The ability to use both manual and power tools makes screw nails convenient and accessible for various projects, regardless of the skill level of the user. This ease of installation saves time and effort, making screw nails a popular choice among professionals and DIY enthusiasts alike.

C. Versatility:

Screw nails offer remarkable versatility in terms of their applications. They can be used with a wide range of materials, including wood, metal, and certain plastics. This versatility makes screw nails suitable for various projects, such as woodworking, construction, furniture assembly, and more. Whether you're building a wooden structure, installing cabinets, or working on metal brackets, screw nails provide a reliable fastening solution across different materials. This flexibility eliminates the need for different types of fasteners, simplifying the selection process and reducing inventory requirements.

D. Enhanced Resistance:

The threaded design of screw nails contributes to their enhanced resistance to external forces and vibrations. The threads create a tighter connection, reducing the likelihood of the nail becoming loose or dislodged due to movement or vibrations. This increased resistance makes screw nails particularly well-suited for applications where durability and longevity are essential. Whether it's securing components in a high-traffic area or withstanding environmental factors, screw nails provide a reliable fastening solution that maintains its integrity over time.

III. How do you make a screw go in easier?

To ensure optimal results and maximize the benefits of using screw nails, here are some helpful tips to consider when working with these versatile hardware fasteners:

A. Pre-Drilling:

In certain situations, particularly when working with hardwoods or dense materials, it is advisable to pre-drill pilot holes before inserting screw nails. Pre-drilling helps prevent the splitting of the material and facilitates smoother installation. The pilot hole should be slightly smaller in diameter than the screw nail to ensure a tight fit and prevent any potential damage to the material.

B. Proper Placement:

Proper placement of screw nails is crucial for achieving maximum holding power and stability. When driving the screw nails, ensure they are positioned correctly and driven perpendicular to the surface. This allows for optimal engagement of the threads into the material, resulting in a secure and reliable connection. Carefully consider the placement of the nails to distribute the load evenly and avoid weak spots in the structure.

C. Choosing the Right Length and Gauge:

Selecting the appropriate length and gauge of screw nails is essential to ensure they penetrate the material adequately and provide sufficient holding power. Consider the thickness of the materials being fastened and consult the manufacturer's recommendations or seek professional advice if necessary. Using screw nails that are too short may not provide enough grip while using ones that are too long can lead to splitting or protrusion on the opposite side of the material.

D. Mind the Material:

Different materials may require specific considerations when using screw nails. For example, when working with softer materials like drywall or particleboard, take care not to overdrive the screw nails, as this can cause the material to crack or break. Additionally, when fastening metals, choose screw nails specifically designed for metal applications to ensure compatibility and optimal performance.

E. Use Proper Tools:

When installing screw nails, use appropriate tools such as a hammer or a power drill with the correct size and type of driver bit. Ensure that the tool is in good working condition to achieve proper insertion without damaging the screw nails or the material. Using the right tools will result in efficient installation and minimize the risk of stripping or damaging the screw nail head.

By following these tips, you can enhance the effectiveness and efficiency of using screw nails in your projects. Whether you're working on construction, woodworking, or other applications, these considerations will help you achieve secure and long-lasting fastening results. Take the time to plan and prepare before installing screw nails to ensure optimal performance and a successful outcome.

IV. Where to Find the Best Screw Nails?

When it comes to finding the best quality screw nails for your projects, it's essential to rely on reputable suppliers that offer a wide range of options. As professionals working for our esteemed company, we take pride in offering the best Screw Nails to our customers.

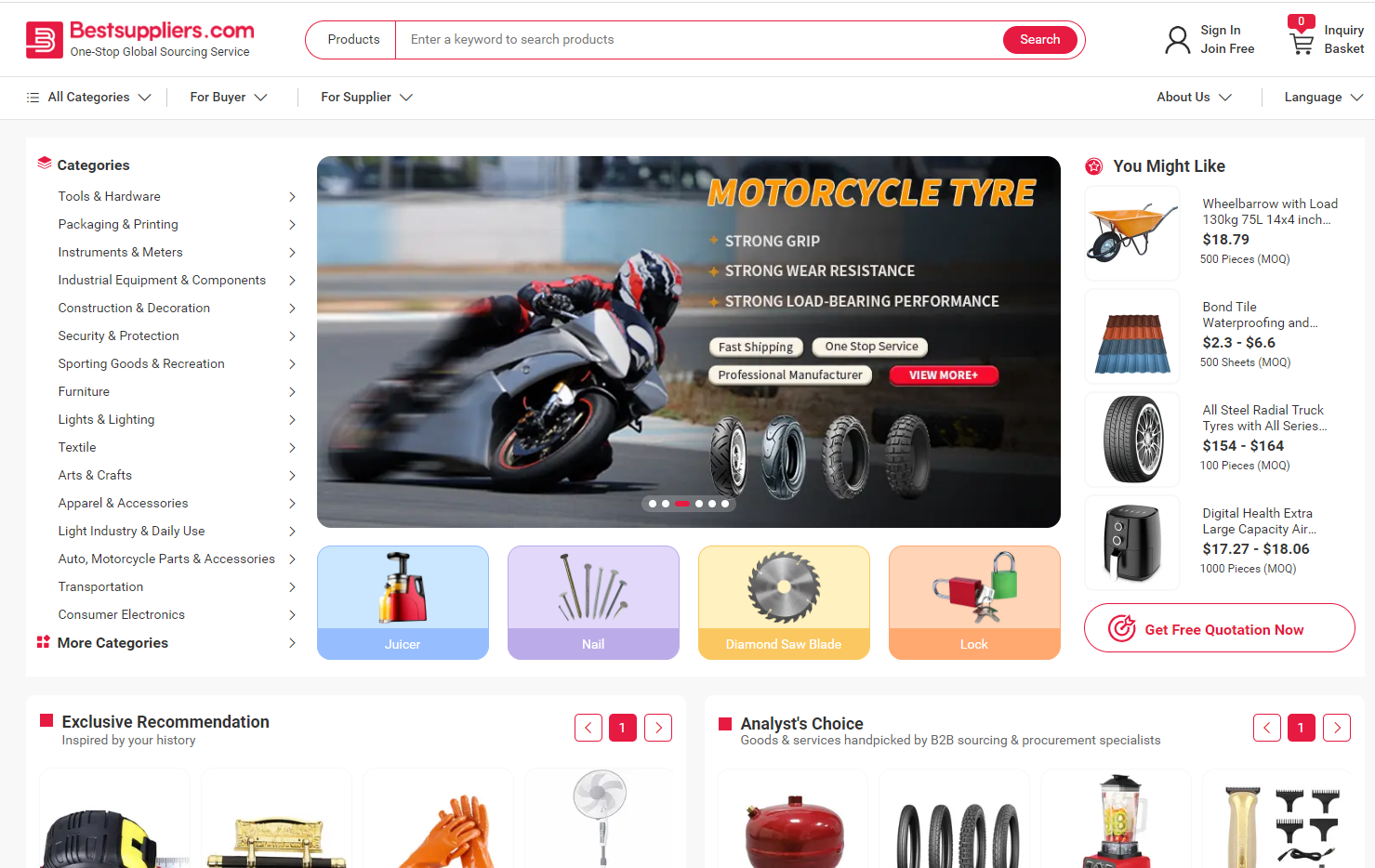

Our platform is a trusted marketplace that showcases a vast selection of top-notch Screw Nails from reputable manufacturers and suppliers. Bestsuppliers website offers a user-friendly interface, making it easy to browse and find the perfect screw nails for your specific needs. With our commitment to quality and customer satisfaction, Best Suppliers ensures that you have access to top-notch screw nails that deliver exceptional performance and durability.

Conclusion

In summary, screw nails offer several advantages that set them apart from traditional nails. Their increased holding power, easy installation process, versatility, and enhanced resistance make them a reliable choice for a wide range of applications. Whether you're working on a construction project, assembling furniture, or undertaking a woodworking task, screw nails provide a secure and durable fastening solution that ensures the longevity and stability of your work. Remember to source Screw Nails from www.bestsuppliers.com, considering the specific project requirements.