Everything You Need to Know About Drywall Screws: The Ultimate Guide

INTRODUCTION

Drywall screws are a fundamental component in any construction or renovation project involving drywall installation. These versatile fasteners play a crucial role in securely attaching drywall sheets to studs or other framing materials. In this comprehensive guide, we will delve into the world of drywall screws, exploring their various types, sizes, applications, and best practices. Whether you're a seasoned professional or a DIY enthusiast, understanding drywall screws will empower you to achieve high-quality and long-lasting results in your projects.

I. What are Drywall Screws?

Drywall screws are an essential component in the world of construction and home improvement. These specialized fasteners are specifically designed to securely attach drywall sheets to framing materials such as studs or joists. Unlike regular screws, drywall screws have unique features that make them ideal for this particular application. Understanding the different types, sizes, and best practices associated with drywall screws is crucial for achieving sturdy and long-lasting drywall installations.

II. What are the Types of Drywall Screws?

A. Coarse Thread Drywall Screws:

Coarse thread drywall screws are the most commonly used type for standard drywall installations. These screws have wide, deep threads that provide excellent holding power in gypsum boards. The coarse threads grip the drywall material firmly and securely to the underlying framing, ensuring a solid attachment. They are ideal for attaching drywall to wood studs or other wooden framing materials. Coarse thread screws are available in various lengths and diameters to accommodate different drywall thicknesses and project requirements.

B. Fine Thread Drywall Screws:

Fine thread drywall screws are specifically designed for attaching drywall to metal studs. Unlike coarse thread screws, they have thinner and closer-spaced threads. The fine threads enable better control during installation and offer increased precision when securing drywall to metal framing. The finer threads also minimize the risk of damaging the metal studs while providing sufficient grip and stability. Fine thread drywall screws are available in different lengths and gauges to accommodate various thicknesses of drywall and metal framing.

C. Self-Drilling Drywall screws:

Self-drilling drywall screws are a time-saving option that eliminates the need for pre-drilling pilot holes. These screws feature a sharp, drill-like point that can penetrate both the drywall and the underlying framing material. As you drive the screw into position, the self-drilling tip cuts through the drywall and creates its own pilot hole, allowing for easy installation. Self-drilling screws are particularly useful when working with dense materials or when a large number of screws need to be installed quickly. They are available in various lengths and diameters to suit different drywall thicknesses and project requirements.

Understanding the different types of drywall screws is crucial for choosing the right one for your specific project. Consider the material of the framing, the type of drywall being installed, and the desired level of precision and convenience when selecting the appropriate drywall screw type. Using the correct type of screw will ensure a strong and reliable attachment, resulting in a professional and long-lasting drywall installation.

III. What Factors should I consider when selecting the size of Drywall Screws?

A. Length:

Drywall screws come in various lengths to accommodate different drywall thicknesses and installation requirements. The length of the screw is determined by the thickness of the drywall and the depth of penetration required into the framing material. Common lengths for drywall screws range from 1 inch to 3 inches or more. For standard 1/2-inch thick drywall, 1-1/4 inch or 1-5/8 inch screws are commonly used. Thicker drywall, such as 5/8 inch or 3/4 inch, may require longer screws, typically 2 inches or more. It's important to choose the appropriate screw length to ensure a secure attachment while avoiding damaging the drywall or protruding through the framing material.

B. Diameter:

Drywall screws are available in different diameters, commonly referred to as the screw's gauge. The most common diameter for drywall screws is #6, but #8 screws are also commonly used. The diameter of the screw affects its holding power and the size of the hole it creates in the drywall. The appropriate diameter is typically determined by the thickness and weight of the drywall being installed. Thicker and heavier drywall may require larger diameter screws for increased stability and support.

C. Gauge:

The gauge of a drywall screw refers to the thickness of the shank or core of the screw. The lower the gauge number, the thicker the screw. The most common gauge for drywall screws is 25, but 23 gauge screws are also available. The gauge of the screw is selected based on the weight of the drywall and the framing material. Heavier drywall or applications with increased load-bearing requirements may necessitate the use of thicker gauge screws to ensure proper support and prevent sagging or failure.

IV. How should I place the Drywall Screws for optimal results?

A. Drywall Installation:

The primary and most common application of drywall screws is in the installation of drywall sheets. These screws are used to attach the drywall panels to the underlying framing, such as wood studs or metal studs, creating a secure and stable wall or ceiling surface.

B. Wood-to-Wood Connections:

Drywall screws are also utilized for wood-to-wood connections in various construction projects. They can be employed to join wooden boards, panels, or trim pieces together, providing a strong and durable connection.

C. Metal Stud Framing:

In projects involving metal stud framing, drywall screws are used to secure drywall sheets to the metal studs. The specific type of drywall screw, such as fine thread or self-drilling, is often selected to ensure optimal attachment and stability in this application.

D. Other Applications:

Drywall screws have versatile applications beyond just drywall installation. They can be used in woodworking projects, furniture assembly, and other general construction tasks where a secure and reliable fastening is required.

V. What are some common mistakes to avoid when using Drywall Screws?

A. Using incorrect Screw Types:

Using the wrong type of screw for the specific application can lead to subpar results. Make sure to select the appropriate screw type, such as coarse thread for standard drywall or fine thread for metal studs, to ensure proper attachment and stability.

B. Overdriving or Underdriving Screws:

Both overdriving and underdriving screws can compromise the integrity of the drywall installation. Overdriven screws can damage the drywall, while underdriven screws may not provide sufficient holding power. Use a drill or screw gun with a depth control feature to achieve the correct depth and avoid these issues.

C. Insufficient Screw Spacing:

Inadequate screw spacing can result in loose or sagging drywall. Follow the recommended spacing guidelines, typically around 12 inches apart along the framing members, to ensure a secure and evenly attached drywall surface.

D. Neglecting Pilot Holes:

Neglecting pre-drill pilot holes, especially near the edges and corners of the drywall, can lead to cracking or splitting. Take the time to create pilot holes to prevent damage and ensure a smooth installation.

E. Over-Tightening Screws:

Over-tightening screws can cause damage to the drywall and compromise its structural integrity. Avoid applying excessive force when securing the screws and stop driving once they are flush with the drywall surface.

By following these best practices and avoiding common mistakes, you can achieve a successful and professional drywall installation. Taking the time to properly prepare, select the right screws, and execute the installation with care will result in a sturdy and visually appealing finished product.

VI. Where to Find the Best Drywall Screws?

When it comes to finding the best quality drywall screw for your projects, it's essential to rely on reputable suppliers that offer a wide range of options. As professionals working for our esteemed company, we take pride in offering the best Drywall Screws to our customers.

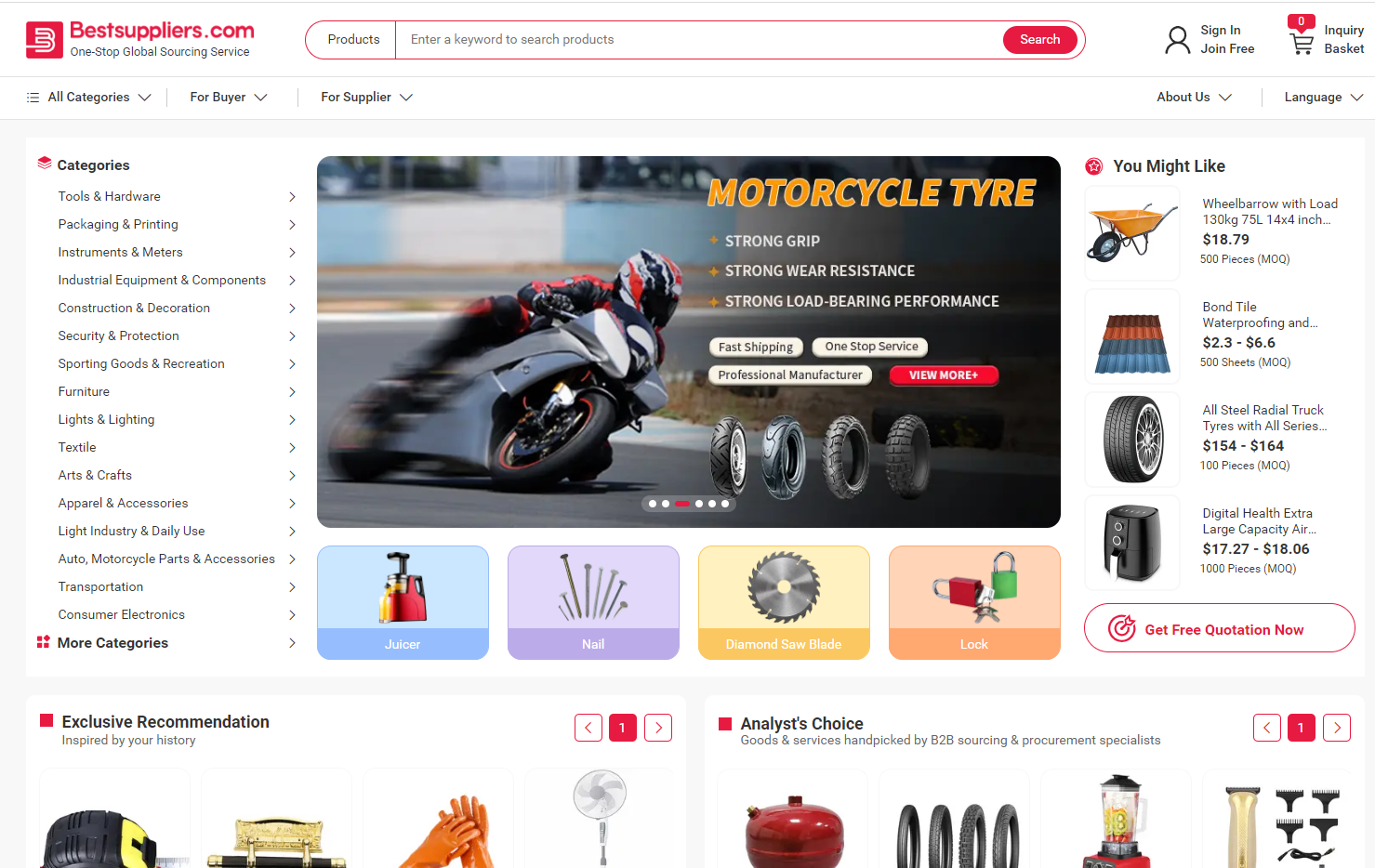

Our platform is a trusted marketplace that showcases a vast selection of top-notch Screw Nails from reputable manufacturers and suppliers. Bestsuppliers website offers a user-friendly interface, making it easy to browse and find the perfect screw nails for your specific needs. With our commitment to quality and customer satisfaction, Best Suppliers ensures that you have access to top-notch screw nails that deliver exceptional performance and durability.

Conclusion:

Drywall screws are essential components for successfully installing a drywall and achieving a professional finish. By understanding the different types, sizes, and best practices associated with drywall screws, you can enhance the quality and durability of your construction or renovation projects. Remember to choose the appropriate screw type, size, and material based on your specific requirements, and follow the recommended installation techniques for optimal results. With this ultimate guide, you can source Drywall Screws from www.bestsuppliers.com to tackle drywall projects like a seasoned pro.