20kg Cooking Gas Cylinder Manufacture for Sale

-

Transport Package:

-

Carton

-

Origin:

-

Zhejiang China

-

Material:

-

Steel Plate

-

Weight:

-

20.0(kg)

-

Working Pressure:

-

18 Bar

-

Water Capacity:

-

45.6L

- Product Details

- {{item.text}}

Quick Details

-

Widely Used:

-

Cooking or Camping

-

Wall Thickness:

-

3.0mm 2.75mm

-

Valve:

-

Brass Valve

-

Output:

-

5000Pcs/Week

-

Export Port:

-

Shanghai,Ningbo and so on

-

Payment:

-

L/C T/T D/P Western Union Paypal Money Gram Other

-

Model NO:

-

B-GP-01-18

20KG Gas Cylinder Description

A 20kg 45.6L gas cylinder is a medium-sized cylinder commonly used for household or industrial applications. The cylinder is made of high-quality steel and can withstand high pressure, ensuring safe and reliable storage of gas. The cylinder has a capacity of 20kg or 45L, making it suitable for a wide range of uses, including cooking, heating, and welding. The cylinder is designed with a valve and a regulator, which makes it easy to control the gas flow and adjust the flame as needed. It is also equipped with a safety device that automatically shuts off the gas flow in case of an emergency. The cylinder is available in different colors and can be customized with logos or labels upon request. Overall, a 20kg 45L gas cylinder is a durable and versatile solution for gas storage needs.

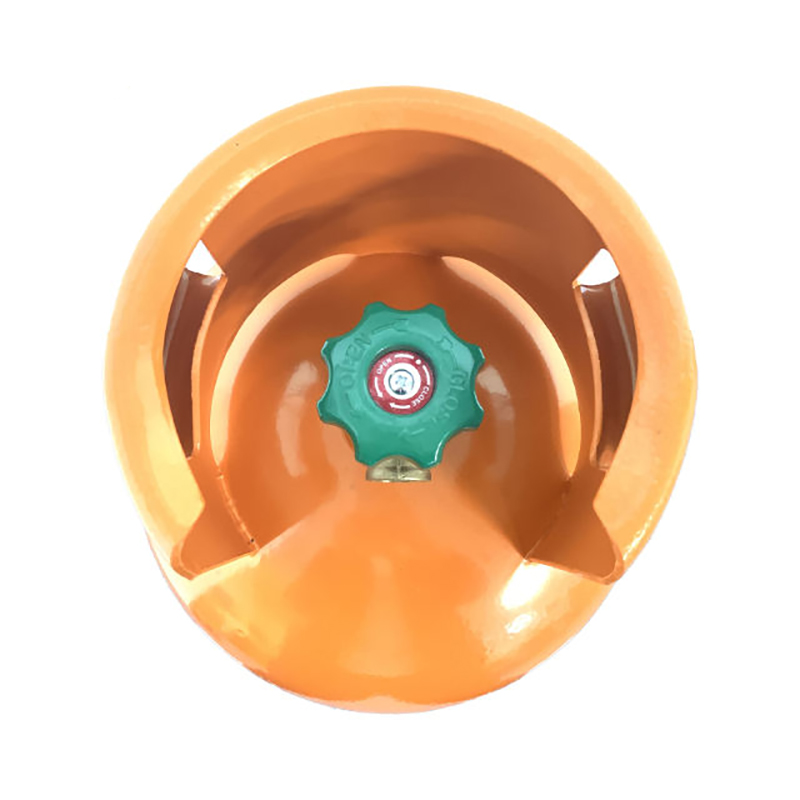

20KG Gas Cylinder Detail Show

An empty steel gas cylinder is composed of several parts, each with its own function. As a supplier, it is important to understand these components and their functions to ensure the quality and safety of the gas cylinder.

Cylinder Body: The cylinder body is the main component of the gas cylinder. It is made of high-quality steel and is designed to withstand high pressure.

Valve of gas cylinder: The valve is responsible for controlling the flow of gas into and out of the cylinder. It is usually made of brass or stainless steel and is designed to prevent gas leaks.

Pressure Relief Device: The pressure relief device is a safety feature that prevents the cylinder from exploding due to overpressure. It is typically a small disc or plug that is designed to release gas when the pressure inside the cylinder exceeds a certain level.

Handle/Collar: The handle or collar is attached to the cylinder body and is used to carry or lift the cylinder. It is usually made of plastic or metal and provides a secure grip.

Base Ring: The base ring is located at the bottom of the cylinder and provides stability when the cylinder is standing upright. It is typically made of metal and is designed to prevent the cylinder from tipping over.

Understanding these components and their functions is essential to ensure the safe and effective use of gas cylinders. As a supplier, we take pride in providing high-quality gas cylinders that meet international safety standards.

20KG Gas Cylinder Productive Process

The production process of a 20kg gas cylinder typically involves the following steps:

Raw material procurement: The main materials used in the production of gas cylinders are steel plates. The steel plates are sourced from trusted suppliers and must meet certain quality standards.

Cutting and forming: The steel plates are cut into the required size and shape, and then pressed into a cylindrical shape using a hydraulic press.

Welding: The two edges of the cylinder are welded together using a high-powered welding machine. This creates a seamless joint that is strong and leak-proof.

Heat treatment: The cylinder is then subjected to a heat treatment process, which helps to reduce any internal stresses and improve its strength and durability.

Surface treatment: The cylinder is cleaned, polished, and painted or coated with a layer of anti-corrosion material to protect it from rust and other types of damage.

Valve and accessory installation: The cylinder valve and other accessories, such as safety devices and pressure gauges, are installed according to the customer's requirements.

Quality control: The finished cylinder undergoes a series of rigorous tests to ensure that it meets the required quality standards. This includes testing for leaks, pressure resistance, and other performance factors.

Packaging and shipping: The cylinders are packaged in a secure manner to prevent damage during transport and shipped to customers.

The entire production process is closely monitored to ensure that all cylinders meet the highest quality standards and are safe for use in a variety of applications.

ODM/OEM

Company Profile

Lanxi Kingway International Trade Co., Ltd. was established in 2006 in Hangzhou City, Zhejiang Province. For many years, Kingway has been committed to supplying commercial lighting, home lighting, customized lighting, and has engaged in combined industry and trade as well as independent exporting. Our main products include lamps, plugs, sockets, luminaire lighting, solar lighting and ect.

Payment & Shipping

FAQ

1. What types of electrical components do you supply?

Answer: We supply a comprehensive range of electrical components, including plugs, sockets, lighting fixtures, and solar lighting solutions for various applications.

2. Can I request samples of electrical components before placing a bulk order?

Answer: Yes, we encourage clients to request samples to evaluate the quality, compatibility, and functionality of our electrical components before making larger commitments.

3. What certifications do your electrical components have?

Answer: Our electrical components comply with relevant international standards, and we can provide certifications and documentation upon request.

4. How do you ensure the quality of your electrical components?

Answer: Quality control is a crucial part of our production process. We conduct thorough inspections and testing to ensure that our electrical components meet industry standards and customer expectations.

5. What is the lead time for production and shipping of electrical components?

Answer: Production and shipping times depend on the type and quantity of the product ordered. We provide estimated timelines upon order confirmation.

6. What payment terms do you offer for electrical components?

Answer: Payment terms are negotiable and typically involve an initial deposit and final payment upon shipment. We accept various payment methods, including bank transfers and letters of credit.