High Quality Ceramic Liner Cylinder For Oilfield Drilling Mud Pump China Factory

FOB Reference Price:

Get Latest Price

US $50 - $500

/Piece |

1 Piece(Min. Order)

-

Transport Package:

-

Packed in wooden case

-

Specification:

-

110,120,130,140,150,160,170,180,190

-

Origin:

-

China

Free Inquiry

Customized Request

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Manufacturing Process:

-

Forging Heat Treatment Carbonitriding chrome

-

Surface Treatment:

-

Spray-Paint Chrome plated inner sleeve

-

Operation Pressure:

-

Atmospheric Pressure Vacuum

-

Material:

-

Alloy Cast Steel High quality carbon steel chrome

-

Payment:

-

L/C T/T Other

-

Export Port:

-

Tianjin;Shanghai

-

Model NO:

-

F1600,F1300,F800

Quick Details

Products Descripition

- Our store provides bimetallic cylinder liners for petroleum mud pumps, cylinder liner is the main part of mud pump,Very easy to wear out due to harsh working environment. But our bimetallic steel sleeve is made of inner and outer sleeves.It has more outstanding advantages!

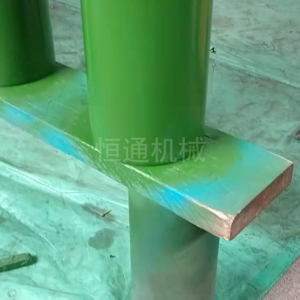

Product Show

Advantage Introduction

- 1.High quality forging materials

- The outer sleeve is made of high-quality carbon steel, and the inner sleeve is made of high-chromium wear-resistant alloy.

- 2.advanced technology

- We use a unique heat treatment process and carbonitriding,the hardness of the cylinder liner has been improved to over HRC62, which extends the service life. The normal service life has been extended to over 800 hours.

- 3.This steel sleeve has high corrosion resistance and wear resistance in harsh environments. The inner wall surface is smooth, long life and high strength.

Packaging&Shipping

Specification

The pump types provided include the following:

1.Gem pump:F-500,F-800,F-1000,F1300,F1600,FB-1300,FB-1600,D-375,D-700.

2.Lanshi Pump:3NB-1300C,3NB-1000,3NB-1000C,3NB-800.

3.Qingzhou Pump:SL3NB-1300A,QZ-1000,QZ-500,QZ-350,QZ-800,SL3NB-1600.

4.Honghua Pump: 3NB-1600F, HHF1300/1600.

5.American Pump: T-500, T-800, T-1000, T-1300, T-1600, A-350PT, A-560PT, A-600PT, A-850PT, A-1100P, A-1400PT,A-1700PT.

6.American Glendon Pump: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11.

7.National Oil Well Pumps: 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-200, 14-P-220, K-700, K-700A, K-500, K-500A.

8.Russian mud pumps: 8T-650, UNBT-600, UNBT-950, UNBT-1180L, UNBT-950A, UBT-400, BT-600, UB-590, UNB-600,8T-310, 8T-650.

Tips:Provide customized services!

Hot Searches