Ring gear for rotary kiln 35crmo Custom Girth Gear Rotary Kiln Parts Large Size

-

Transport Package:

-

Simple packaging, wooden box

-

Specification:

-

6000-10000mm

-

Trademark:

-

HTON

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

CHINA

-

Application:

-

Fastener Machinery Accessory Other

-

Standard:

-

GB EN API650 China GB Code TEMA Other

-

Surface Treatment:

-

Other

-

Production Type:

-

Mass Production Single Production Other

-

Machining Method:

-

Casting CNC Milling CNC Machining Other

-

Material:

-

Steel Alloy

-

Customized according:

-

Customized according to the picture

-

Payment:

-

L/C T/T

-

Export Port:

-

tianjin.shanghai

-

Output:

-

50

-

Model NO:

-

8600mm

Quick Details

-

Customized according:

-

Customized according to the picture

Products Descripition

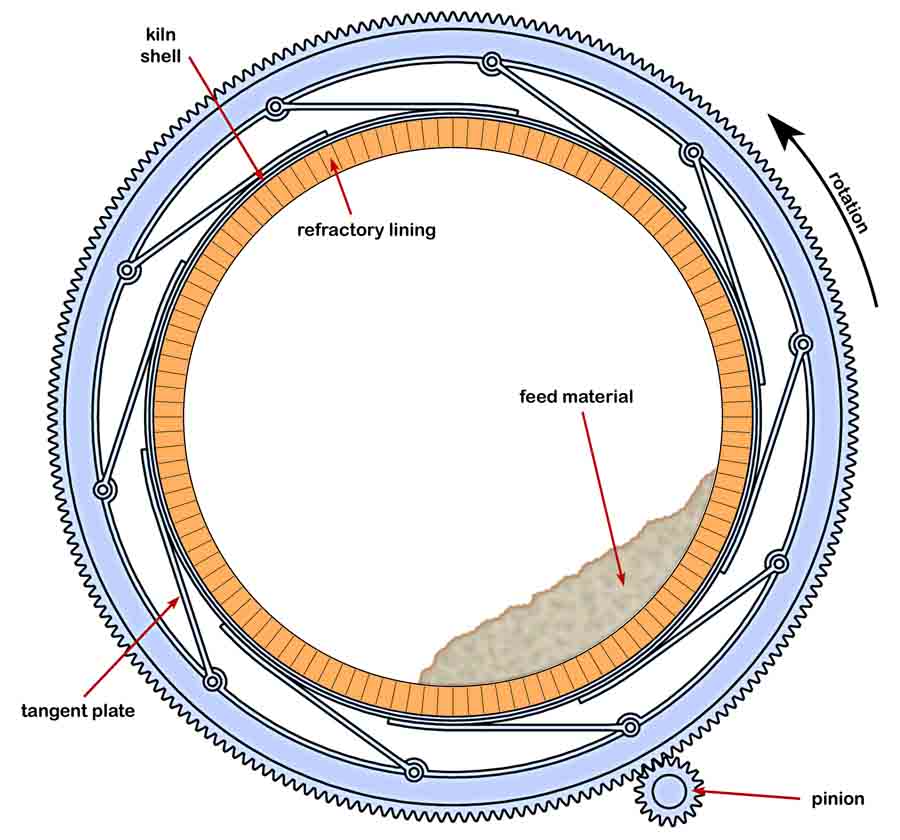

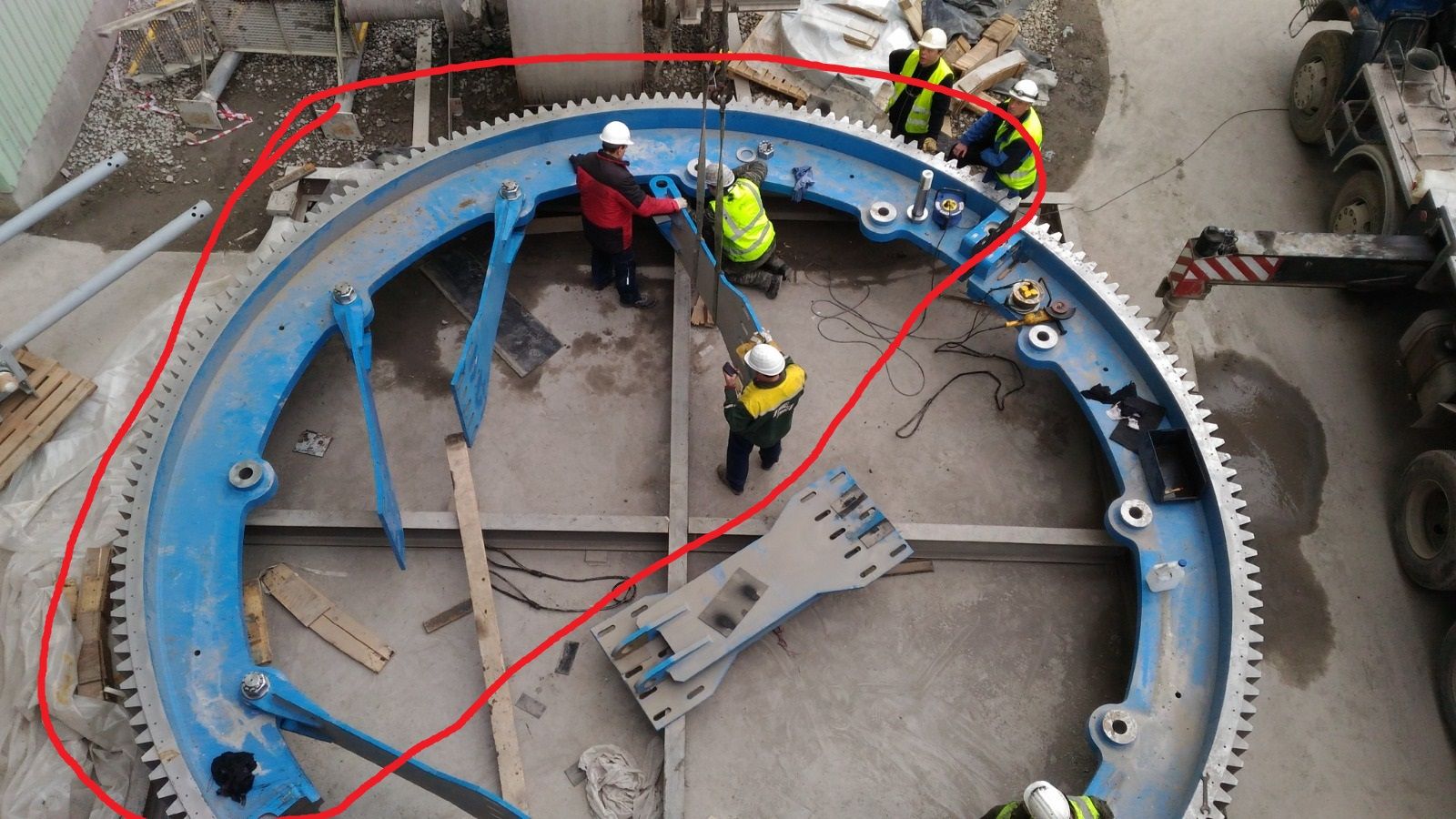

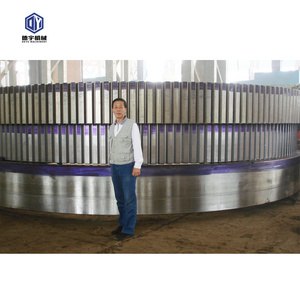

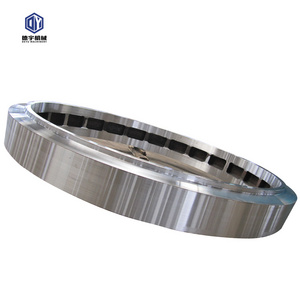

The large ring gear is one of the key components in the cement rotary kiln.Due to the needs of manufacturing capacity, transportation and installation, the Daken circle is composed of two half-couch crotch joints, connected together with opposite screws, and fixed tangentially to the kiln body by a spring plate.The installation quality of the large ring gear directly affects the stability of the transmission system and the stability of operation, which in turn affects the service life of the inner lining and the operating rate of the kiln.After the canine tooth ring is repaired and installed, the radial runout is not greater than 2mm, and the end face runout is not greater than 1.5mm, which requires very high accuracy.To complete the installation and correction of large ring gears with high quality, a scientific and feasible construction plan must be formulated

Specification

Weight: 10~60T

Main material: ZG45, ZG42CrMO

Suitable for industries: cement, electric power, metallurgy, chemical industry, non-metallic minerals and other industries

Product Show

Product Details:

Large gear, also known as large ring gear, is one of the key components of rotary kilns, ball mills and other

equipment. Its quality will directly affect the operation of rotary kilns and ball mills.

Due to the large modulus, large diameter, production, installation, transportation and other problems of large ring gears, two and a half ring gears are combined into one large ring gear.If you have processing requirements for large ring gears, you can call directly or consult online, and we will arrange someone to receive you!