Hydraulic Silent Buffer Damping Detachable 304 Stainless Steel Hinge for Cabinet Door

-

Transport Package:

-

Plastic bag +carton or as customer's request

-

Trademark:

-

Customizable

-

Origin:

-

Guangdong, China

-

Type:

-

Damping Hinge Stainless Steel Hinges 60° Hinge

-

Surface Treatment:

-

Bright Treatment Customizable

-

Material:

-

304 Stainless Steel

- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Cupboard Door Windoor Furniture Table

-

Color:

-

Customizable Black Sliver Gold

-

Style:

-

Hydraulic Modern Minimalist

-

Size:

-

Customizable

-

Other Attention:

-

None

-

Customize:

-

Yes

-

Weight:

-

Customizable

-

Output:

-

80000 Pieces/Month

-

Export Port:

-

Shanghai/Ningbo/Qingdao

-

Payment:

-

L/C T/T Western Union Paypal Money Gram

-

Model NO:

-

PL3-39-1

Soft Close Hinges Description

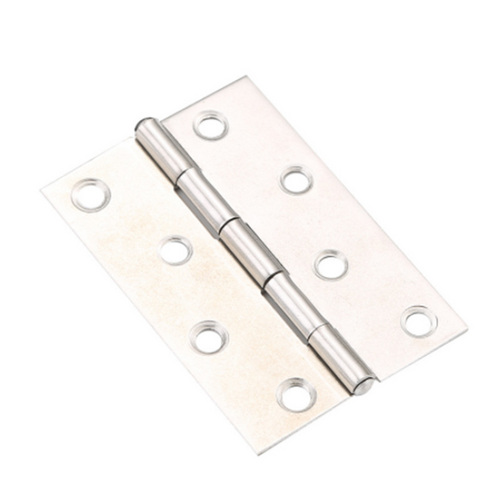

304 stainless steel material: This damping hinge is made of 304 stainless steel, which will not rust and prevent corrosion even if it is soaked in water. High hardness, fine workmanship, the surface is brightly treated, more beautiful, not only durable but also decorative.

Versatile use: This hydraulic soft-close hinge is ideal for connecting cabinet doors, wardrobe doors, TV cabinets, bookcases or other doors.

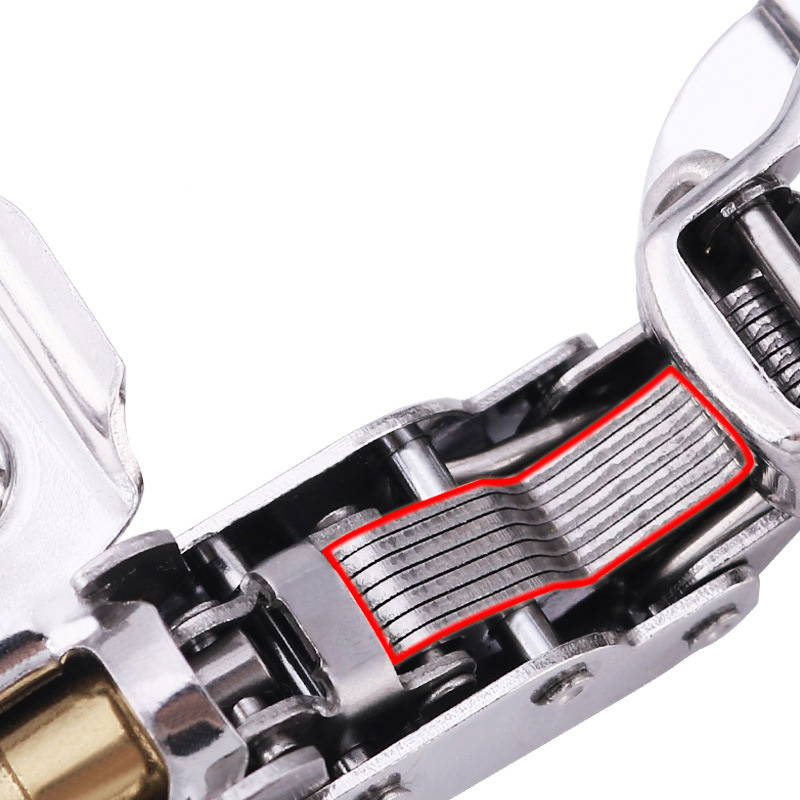

Strong cushioning capacity: This damping hinge is equipped with 7 cushioning arms inside, which has uniform force when opening and closing, and has strong cushioning capacity.

A variety of styles: the base has fixed and self-unloading types. If you don't want to remove it after installing it, you can choose a fixed one; if you want to remove it and clean it after installing it, you can choose a self-disassembling type. Whether it is fixed or self-unloading, there are straight arms, middle bends, and big bends.

Wear-resistant and durable: the hinge cup is 13MM deep, the force area of the slot diameter is 24MM, and the cabinet door is firmly fixed; the stainless steel adjustable screws are more convenient to install; the spring assist arm made of manganese steel is thicker and wider, The force is uniform and will not be deformed; the surface is fixed with stainless steel rivets, which is more stable and not easy to rust; copper hydraulic pump, 60° buffer silent opening and closing.

Intimate service: This hinge has a variety of styles and specifications, you can contact us to choose the style and quantity you need to get a reasonable and favorable quotation.

Detailed Photos And Production Process

The hinges manufacturing involves a series of steps , each of these steps ensure its perfect performance in final finished hinges. So here are the main steps of how he door hinges are made:

1.Raw material thermal treatment:

Firstly , we need to know the hinge manufacturing involves a certain degree of thermal treatment,the raw metal material will firstly heated to make it molten in a smelting unit,for the purpose of forming into various shapes and change its chemical composition.

2.Casting:

The casting is an important machining working step, during the casting process , the metal is melted and then put into the mold to solidify the determined form. After casting , the pieces will be under finishing treatment to have an aesthetic feature.

3.Extrusion:

Extrusion is a working technique that can force the metal against a specially shaped die under high pressure. The extruded hinges are usually stronger in mechanical property than stamped hinges.

4.Deformation:

Deformation of metal into a certain hinge shape is a complex process, that include bending, spinning, rolling, or forging it.The metal needs to be drawn and elongated , and stretched until it obtain a desired form.

5.Cutting:

Removing excess material from metal workpiece is another way to shape it into a hinge component. The cutting is usually accomplished by sawing, drilling , or shearing or laser and waterjet cutting.

6.Secondary production process of hinges:

The secondary production process involves treatment for protection against deterioration and wear.Every time a hinge is used,some of its metal is worn away. Thus some manufacturers will assemble hinge with ball bearing in the middle of each joint.The ball bearings ensure a smoother glide when the hinge is in motion, while for aesthetic consideration, the hinges before sending to customers , will also have a series of finishing treatments such as polishing, burnishing , painting to increase decorative appeal.

Slow Close Hinge Application

This hinge is suitable for drawers, dressers, wardrobes, bedroom doors, etc., and has a wide range of uses.

Product Category

Company Profile

If you are interested in our products,Please feel free to contact us!

FAQ

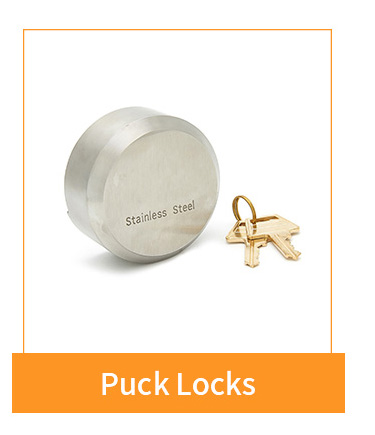

1.What types of hardware, tools, and locks do you supply?

Answer: We provide a diverse range of hardware and tools, including a variety of locks such as padlocks, door locks, and specialty locks. Our tools cover both hand tools and power tools for various applications.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to evaluate the quality, durability, and functionality of our hardware, tools, and locks before committing to a larger order.

3.What is the minimum order quantity (MOQ) for your products?

Answer: The MOQ varies depending on the type of product. Please contact our sales team for specific information about MOQs for locks, tools, or other hardware.

4.How do you ensure the quality of your tools and hardware?

Answer: We implement stringent quality control measures at every stage of production to ensure that our locks and hardware meet the highest standards. Our team conducts thorough inspections and testing.