Widen Turbine Type Diamond Grinding Wheel Saw Blade

-

Manufacturing Process:

-

Sintered

-

Application:

-

Ceramic Stone Refractory Material Concrete Custom

-

Blade Type:

-

Turbine Cutter Head Continuous Boundary Custom

-

Binding Agent:

-

Metal Alloy Custom

-

Weight:

-

0.4-0.9KG

-

Output:

-

100000 pieces/month

- Product Details

- {{item.text}}

Quick Details

-

Export Port:

-

Ningbo

-

Payment:

-

L/C T/T Western Union Paypal Money Gram Other

-

Model NO:

-

WFDSB-002

Diamond Saw Blade Description

Diamond grinding wheel generally come in different sizes and shapes , including ciurcular saw blade, grinding wheel.

Bestsuppliers we provide with this sintered widen turbine diamond grinding wheel saw blade in different colours. they are used for grinding concrete, granite, Marble, Quartz, and aslo other semiconductor materials are an essential tool in various industries, including construction industry. semicondoncutor industry, and gem industry, the widen turbine wheel blade features its durability and long life span, which can self-sharpen by erasing diamond grits during operation; meanwhile our diamond saw blade can work in both wet and dry condition.,and in wet situation , the diamond saw blade can perform even better.

Product Features

1.High cutting effiency

2. High performance in grinding concrete, grante

3.resistance to rust for a great durability

4.Good temperature resistance

What is a Diamond Saw Blade Used For

As we know , diamond is one of the hardest naturally materials ,so diamond saw blade is usually more robust that make it possible to cut even the hardest materials.The diamond blades are also used a lot in semiconductor manufacturing, which can imporve the wafering process and reduce the cost in device fabrication

As we know , diamond is one of the hardest naturally materials ,so diamond saw blade is usually more robust that make it possible to cut even the hardest materials.The diamond blades are also used a lot in semiconductor manufacturing, which can imporve the wafering process and reduce the cost in device fabrication

What are the three types of saw blades?

What are the three types of saw blades?

The common used diamon saw blades are in three types for constrcution site

1. Segmented Rim

the segmented rim blade is a popular blade for working site where there is no access to water source to cool blade , as with the diamond saw blade, the overheating problem occurs a lot . Thisa type of blade is divided into 10-14 segments with a deep groove in between each section. the deep groov can play an important role in constant heating transfer while working , and avoid the overheating problem.

2.Turbo rim blade

the turbo rim is for the fastest cuts in both wet or dry applications. it can easily create the fast and smooth cuts for tile and stones

3.continuous rim:

The continuous rim is used for the surface cutting of marble, granite and porcelain to make a perfect cutting.These blades are most ordinarily available in 4" to 14" diameters. the continous rim saw blade is mostly for wet cutting。

The Pros and Cons of Dry Cutting with Diamond Blade :

pros of dry cutting

1.sharp details: dry-cutting saw is known for detailing and finishing work, which can creat a smoother and flatter surface for decorative patterns.

2. longer-lasting blade: even though all diamond blades feature long last life, which is a truth . but those dry cutting saw blades are even more durable and heat-resistant.Since they have no water source to provide cooling

3. No water required; as the wet cutting requires a constant stream of pressurized water, dry cutting is more convenient for worker working in the environment where there is no water soruce or in the job site where need to stay dry.

4. more safe without water splashing: the dry cutting uses specialised diamond blade that can withstand overheating. so it will not generate the water spraying on the cutting surface , the contractor when in use of the dry cutting saw, he can carry on with constrcution work.

5.simplied cutting: dry cutting is a simply striaghtforward work, it can create shallow and straight cuts easily.

cons of dry cutting

1.No curved cuts: the dry cutting is not suitable for curved line treatment , as it can only creat the straight line

2. dust generation: the dust released during sawing will bring health issue to worker

3.intermittent use:dry cutting will have interval time between cuttings, so it will require more downtime,

Diamond Saw Blade Detail Show

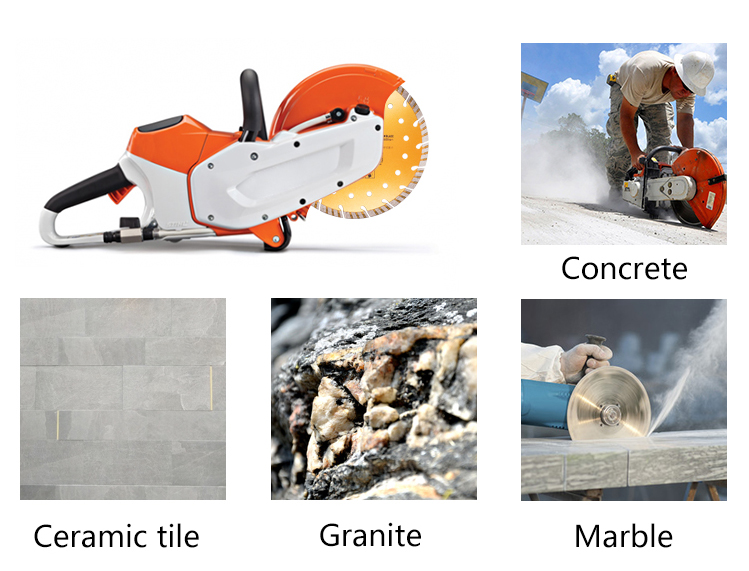

Diamond Saw Blade Application

Diamond grinding wheel saw blade is used widely in cutting stone, concrete, asphalt, bricks, coal balls, glass, and ceramics in the construction industry; cutting semiconductor materials in the semiconductor industry; and cutting gemstones, including diamonds, in the gem industry. Of course, it can be also used in abrasiving material. When cutting or grinding gemstones, you'd better use water and oil as a lubricant. If you wish to avoid imparting oiliness or greasiness to the material, you'd better use water to work. Nevertheless, both work to prevent overheating of the diamond saw blade while cutting.

Diamond Saw Blade Manufacturing Process

Company Profile

If you are interested in our products,Please feel free to contact us!

FAQ

1.What types of hardware, tools, and locks do you supply?

Answer: We provide a diverse range of hardware and tools, including a variety of locks such as padlocks, door locks, and specialty locks. Our tools cover both hand tools and power tools for various applications.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to evaluate the quality, durability, and functionality of our hardware, tools, and locks before committing to a larger order.

3.What is the minimum order quantity (MOQ) for your products?

Answer: The MOQ varies depending on the type of product. Please contact our sales team for specific information about MOQs for locks, tools, or other hardware.

4.How do you ensure the quality of your tools and hardware?

Answer: We implement stringent quality control measures at every stage of production to ensure that our locks and hardware meet the highest standards. Our team conducts thorough inspections and testing.